Carbon material preparation method

A carbon material and carbonization temperature technology, which is applied in the field of preparation of heteroatom-doped carbon materials, can solve the problems of difficulty in controlling the pore structure of carbon materials, low heating rate of carbonization by soft template method, and difficulty in obtaining mesoporous carbon materials. Narrow mesopore pore size distribution, improved hydrophilicity, and fewer steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

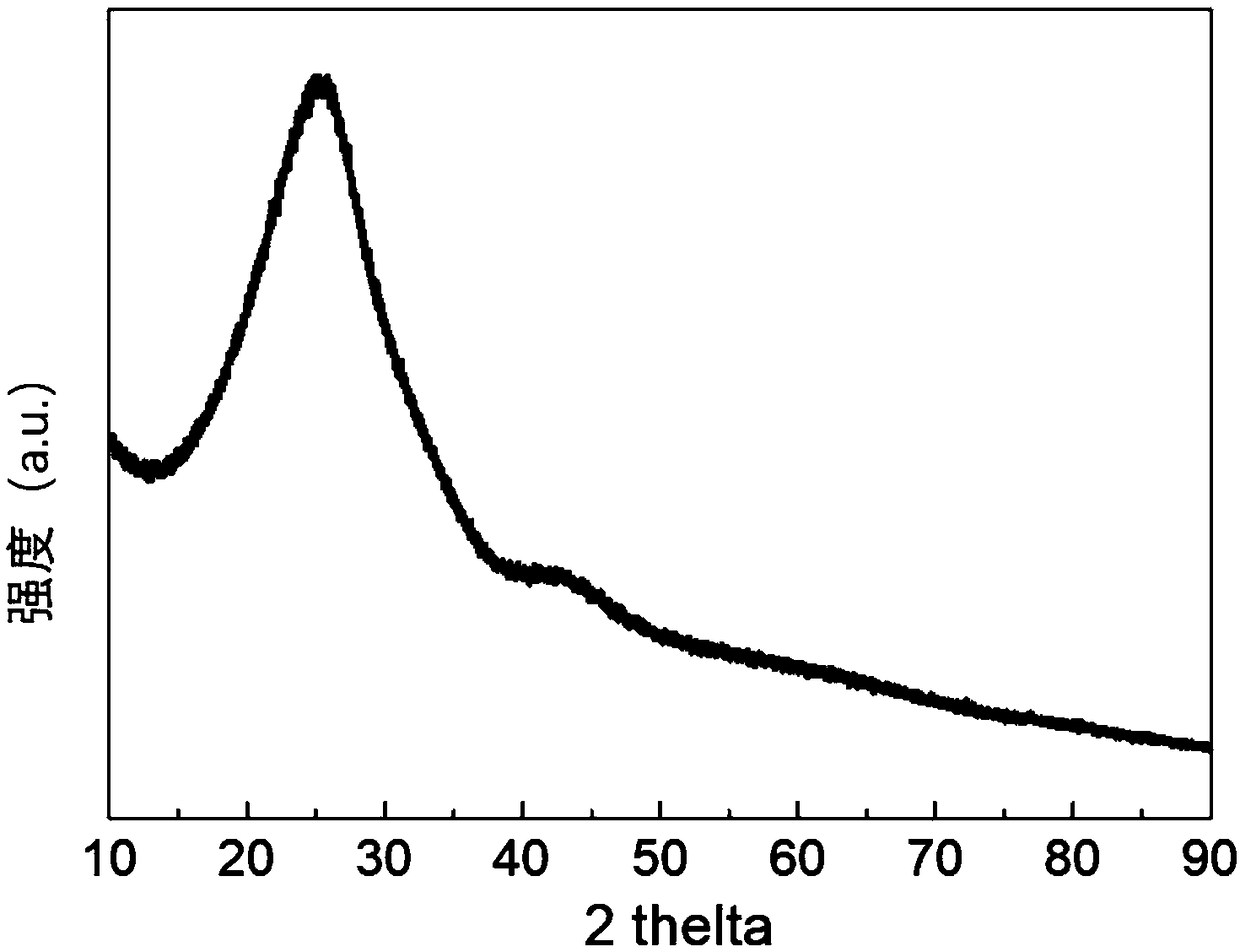

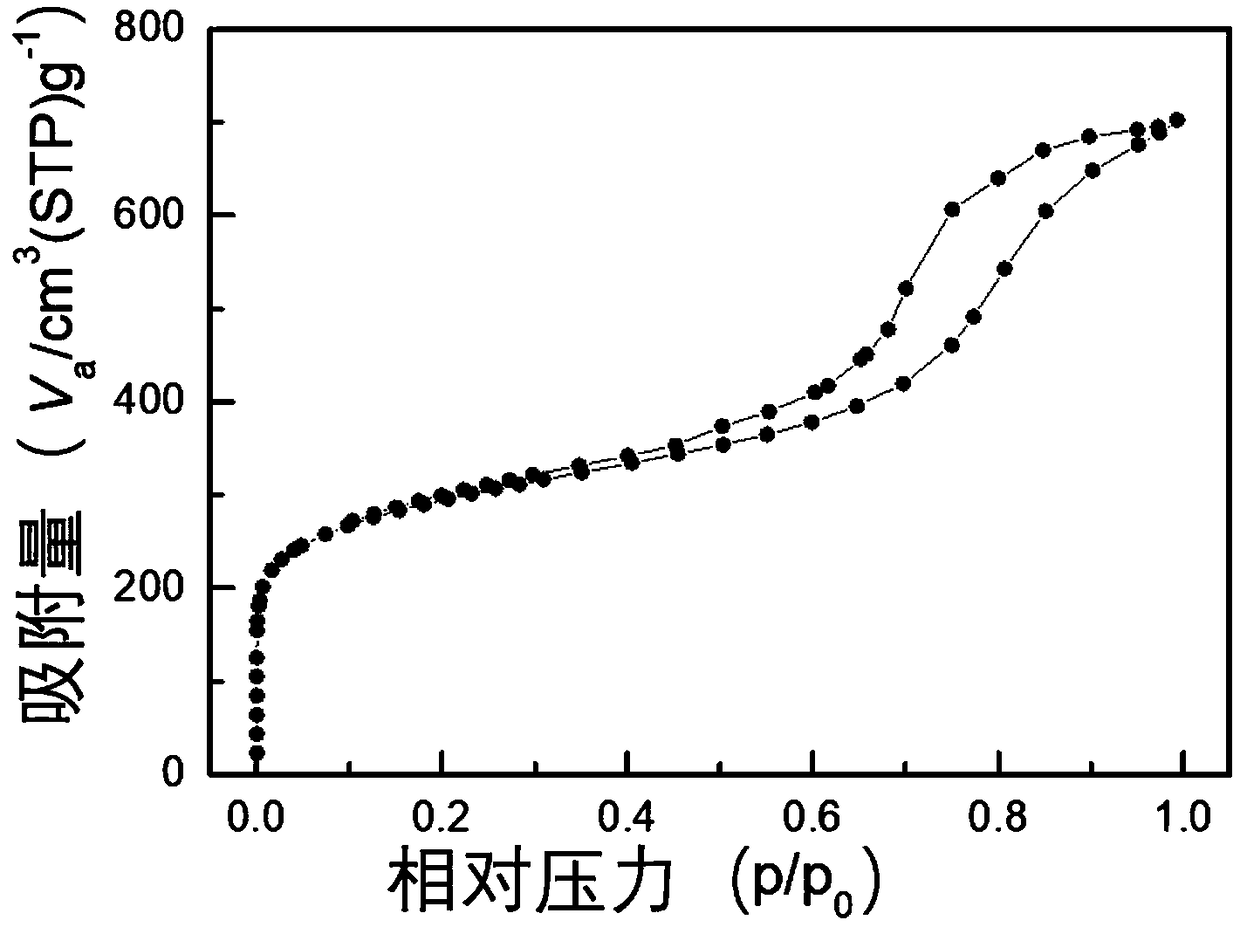

[0028] The preparation method of the oxygen-doped carbon material provided by the present invention includes: 1) selection and preparation of the precursor: selecting a suitable precursor or synthesizing a special precursor; preparation of the oxygen-doped carbon material: 2) high-temperature carbonization: The precursor is placed in a crucible and covered with a crucible lid, and then placed in a muffle furnace. Under an air atmosphere, a heating program is set to raise the temperature to the carbonization temperature at a certain heating rate, and then cool down to the carbonization temperature after a certain period of time. After washing and drying at room temperature, the oxygen-doped carbon material is obtained.

[0029] During the entire preparation process, the relative ratio of the mass of the precursor to the volume of the crucible, the structure and type of the precursor, the heating rate of carbonization, the carbonization temperature and the holding time will affec...

Embodiment 1

[0032] This embodiment provides a method for preparing an oxygen-doped carbon material and the prepared oxygen-doped carbon material.

[0033] Weigh 2g of sulfuric acid-treated sucrose, place them in 15mL, 20mL, 30mL, and 50mL crucibles respectively, cover the crucible lids, put them into a muffle furnace, set the heating program: heat up to 900°C at a rate of 20°C / min, and They were respectively kept warm for 0 min, and were taken out after cooling, and a nitrogen-oxygen-doped mesoporous carbon material was obtained after grinding. The results showed that the yields of the obtained carbon materials were 43.1% (15mL crucible), 41.8% (20mL crucible), 40.2% (30mL crucible), 36.3% (50mL crucible).

Embodiment 2

[0035] This embodiment provides a nitrogen and oxygen doped mesoporous carbon material and a preparation method thereof.

[0036]Weigh 0.05 mol of p-phenylenediamine and dissolve in 30 mL of methanol, weigh 0.1 mol of sulfuric acid and dissolve in 50 mL of deionized water. In an ice-water bath, slowly drop the p-phenylenediamine methanol solution into the sulfuric acid solution, stir and react at room temperature for 1 hour, distill off the solvent under reduced pressure, and dry in vacuum to obtain the precursor p-phenylenediamine dihydrogensulfate. Put 2 g of p-phenylenediamine dihydrogensulfate obtained in a crucible, cover the crucible lid, put it into a muffle furnace, set the temperature rise program: raise the temperature to 900°C at a rate of 20°C / min, and keep warm for 0min, 30min, 60min, 90min, then lower the temperature to room temperature, take it out, and get a nitrogen-oxygen-doped mesoporous carbon material after grinding. According to different holding times, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| mesopore | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com