Super controlled release type polycarboxylate slump retention agent and preparation method thereof

An ultra-slow-release polycarboxylic acid technology, applied in the field of ultra-slow-release polycarboxylic acid slump-retaining agent and its preparation, can solve the problems of high numerical value and complex production process, and achieve simple feeding procedures, simple process, and reduction The effect of low water rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

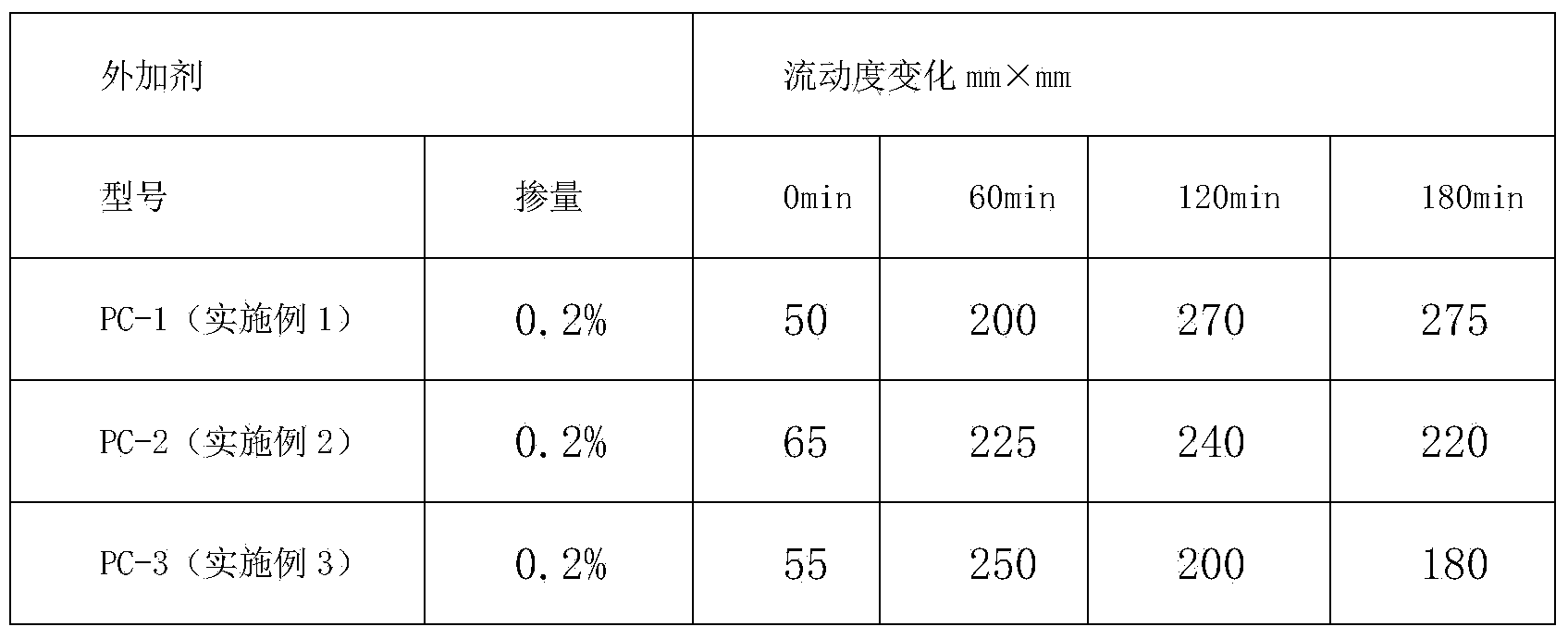

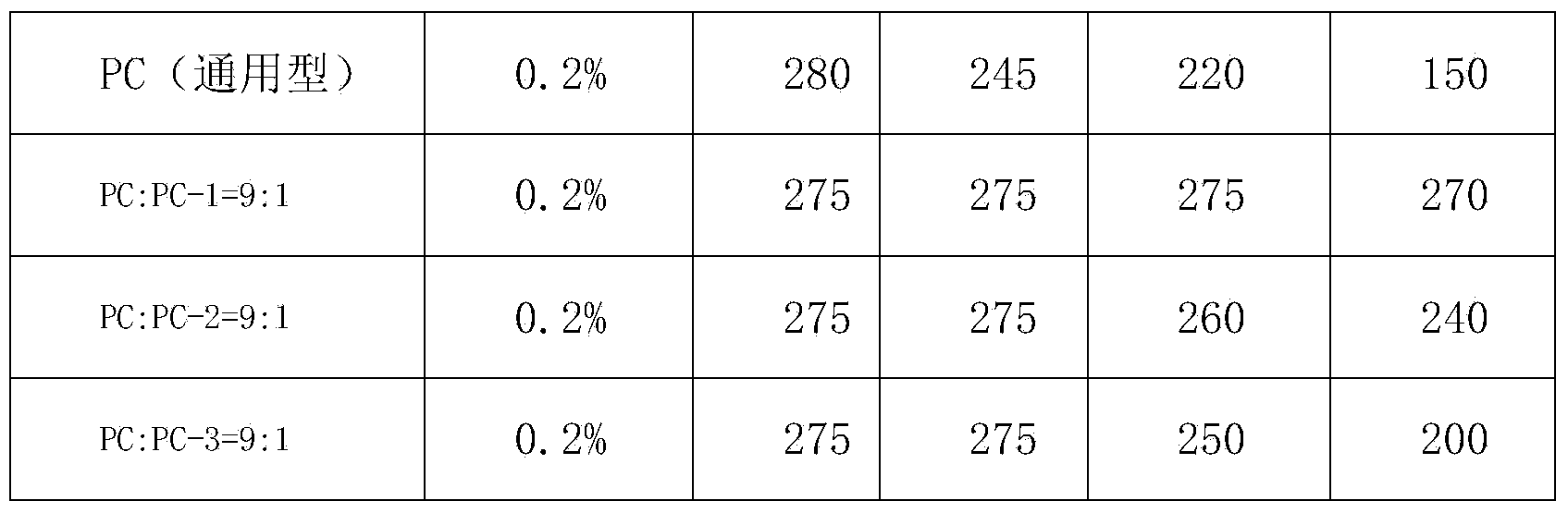

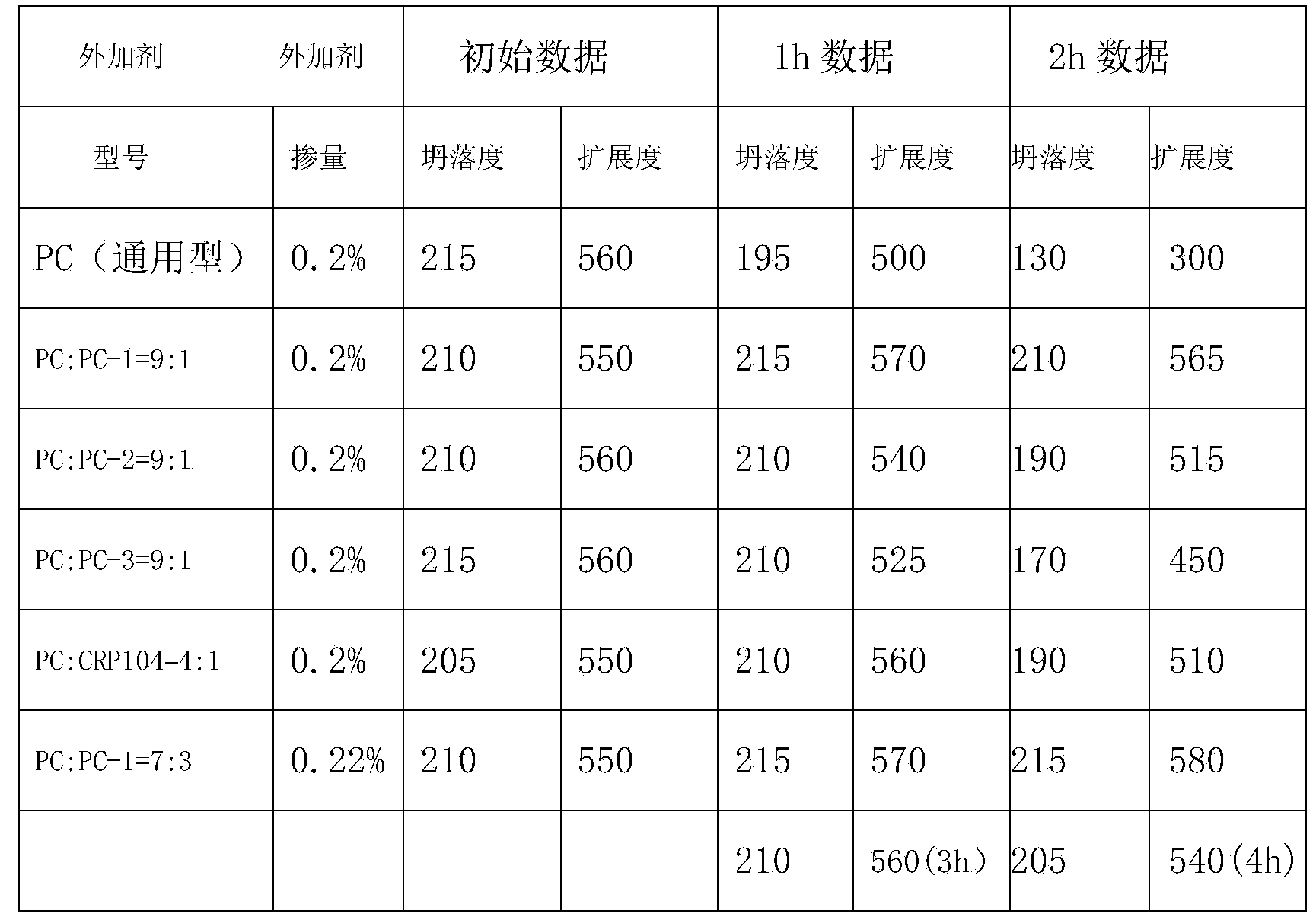

Examples

Embodiment 1

[0023] Put 120.00 parts of isopentenyl polyoxyethylene ether with a molecular weight of 2400 and 75 parts of water into a reaction container, raise the temperature, stir at a temperature of 50±5°C to completely dissolve the reactants, and then add polyethylene glycol into the container. Diol maleic acid monoester 12g, add dropwise the aqueous solution of 7.2 parts of acrylic acid + 1.09 parts of sodium methacrylate + 22.75 parts of hydroxypropyl acrylate + 31.04 parts of water and 45.00 parts of 5% ammonium persulfate solution, and control the dripping Acceleration, drop at 120±10 minutes and 150±10 minutes respectively, keep the temperature at 50±5°C, and continue the reaction for 1 hour. After cooling, add about 5 parts of 30% sodium hydroxide solution to adjust the pH to 6.5±0.5 to obtain the 50% polycarboxylate high-performance concrete water reducer of the present invention.

Embodiment 2

[0025] Put 120.00 parts of isopentenyl polyoxyethylene ether with a molecular weight of 2400 and 75 parts of water into a reaction container, raise the temperature, and stir at a temperature of 65±5°C to completely dissolve the reactants, and then add polyethylene glycol into the container. 12 parts of diol maleic acid diester, dropwise add 7.2 parts of acrylic acid + 1.09 parts of sodium methacryl sulfonate + 22.75 parts of vinyl acetate + 31.04 parts of water and 45.00 parts of 5% ammonium persulfate solution, dropwise Acceleration, drop at 120±10 minutes and 150±10 minutes respectively, keep the temperature at 50±5°C, and continue the reaction for 1 hour. After cooling, add about 5 parts of 30% sodium hydroxide solution to adjust the pH to 6.5±0.5 to obtain the 50% polycarboxylate high-performance concrete water reducer of the present invention.

Embodiment 3

[0027]Put 120.00 parts of isopentenyl polyoxyethylene ether with a molecular weight of 2400 and 71 parts of water into a reaction container, raise the temperature, stir at a temperature of 50±5°C to completely dissolve the reactants, and then add polyethylene glycol into the container. A total of 12g of diol maleic acid monoester and polyethylene glycol maleic acid diester is added dropwise with an aqueous solution of 7.2 parts of acrylic acid+1.09 parts of sodium methacrylate sulfonate+22.3 parts of hydroxyethyl acrylate+30.59 parts of water and 45.00 parts of 5% ammonium persulfate solution, control the dropping speed, finish dropping at 120±10 minutes and 150±10 minutes respectively, keep the temperature at 50±5°C, and continue the reaction for 1 hour. After cooling, add about 5 parts of 30% sodium hydroxide solution to adjust the pH to 6.5±0.5 to obtain the 50% polycarboxylate high-performance concrete water reducer of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com