A kind of lithium-ion battery ternary cathode material and preparation method thereof

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, electrical components, secondary batteries, etc., can solve the problems of poor electrolyte contact, poor electrochemical performance, and low cycle capacity, and achieve improved electrochemical performance, The effect of low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of lithium ion battery ternary cathode material provided by the invention comprises the following steps:

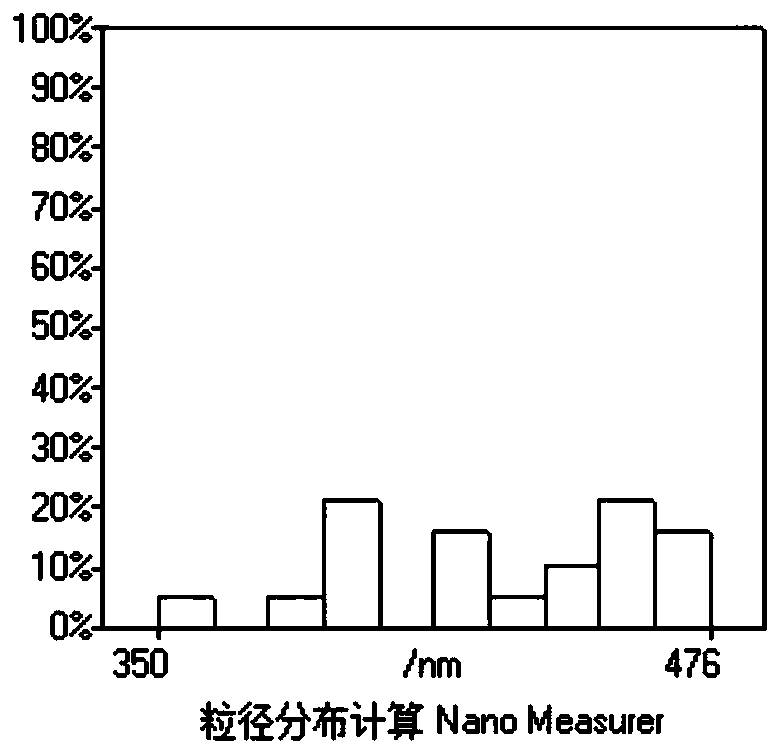

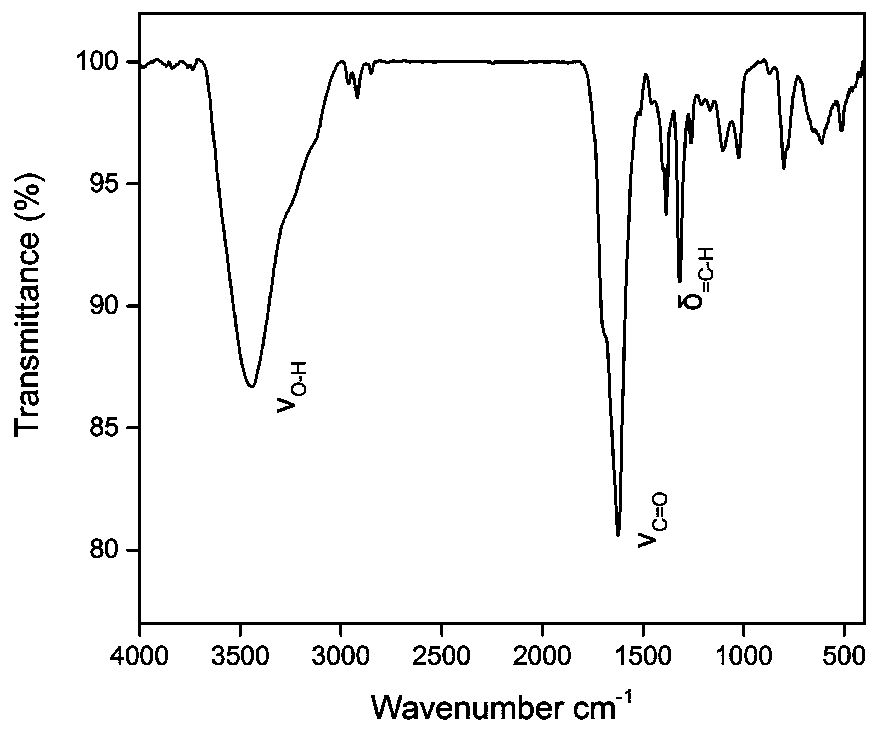

[0037](1) After mixing carbon spheres, nickel salts, cobalt salts and manganese salts, add absolute ethanol, and stir to obtain a mixed suspension; wherein, the surface of the carbon spheres contains oxygen-containing functional groups, and its diameter is 300nm-700nm; The carbon spheres are prepared according to the following method: disperse the carbon source in deionized water to obtain a transparent and uniform solution, and perform a hydrothermal reaction to obtain a carbon sphere template. The preferred preparation process of carbon spheres is: using glucose or sucrose as a carbon source, stirring, preferably ultrasonic stirring, for 20-60 minutes, so that the carbon source is dispersed in deionized water to obtain a transparent and uniform solution, in which the glucose or sucrose The mass concentration is 5%-10%, at 150°C-220°C, prefe...

Embodiment 1

[0047] Dissolve 2.4g of glucose in 30ml of deionized water, stir it for 1 hour, put it in a 50ml hydrothermal kettle at 180°C for 10 hours, centrifuge, wash with water and ethanol, and then freeze-dry to obtain the carbon sphere template.

[0048] According to the metal content of 200mg, add a certain amount of NiCl in 80ml absolute ethanol 2 ·6H 2 O, CoCl 2 ·6H 2 O, MnCl 2 4H 2 O, wherein the ratio of the three metal elements is 8:1:1, while adding 200 mg of carbon sphere template, and then stirring the suspension obtained by ultrasonication. Then slowly add 80ml of ammonia solution with a concentration of 0.07mol / L, continue to stir for 4h, centrifuge and wash, and dry in a blast dryer at 60°C.

[0049] The dried precursor was calcined at 500 °C for 3 h in the air atmosphere to obtain the metal oxide, and then a certain amount of anhydrous Li was added 2 CO 3 , to ensure that the atomic ratio of Li to metal in the material is 1.1:1, after grinding, the temperature is ...

Embodiment 2

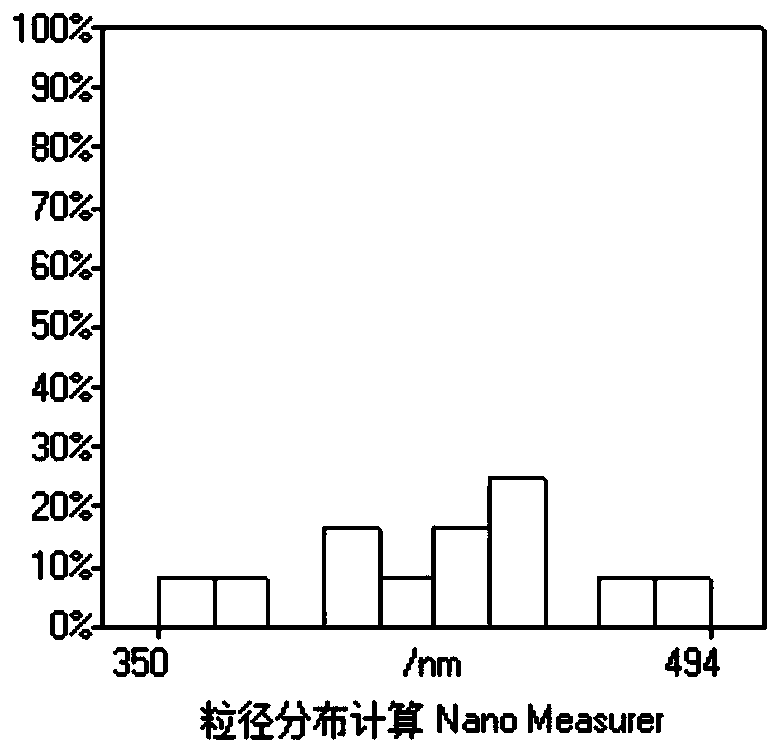

[0063] Dissolve 2.4g of glucose in 30ml of deionized water, stir it for 1 hour, put it in a 50ml hydrothermal kettle at 180°C for 10 hours, centrifuge, wash with water and ethanol, and then freeze-dry to obtain the carbon sphere template.

[0064] According to the metal content of 200mg, add a certain amount of NiCl in 80ml absolute ethanol 2 ·6H 2 O, CoCl 2 ·6H 2 O, MnCl 2 4H 2 O, wherein the ratio of the three metal elements is 1:1:1, while adding 200 mg of carbon sphere template, and then stirring the suspension obtained by ultrasonication. Then slowly add 80ml of ammonia solution with a concentration of 0.07mol / L, continue to stir for 4h, centrifuge and wash, and dry in a blast dryer at 60°C.

[0065] The dried precursor was calcined at 500 °C for 3 h in the air atmosphere to obtain the metal oxide, and then a certain amount of anhydrous Li was added 2 CO 3 , ensure that the atomic ratio of Li to metal in the material is 1.2:1, heat up to 750°C after grinding and ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com