Positive electrode material, preparation method thereof and lithium ion battery

A cathode material and matrix material technology, applied in the field of lithium ion batteries, cathode materials and their preparation, can solve the problems that restrict the industrial application of ultra-high nickel layered single crystal cathode materials, the deterioration of first cycle capacity and cycle capacity, Li/Ni Mixed row and other problems, to achieve the effect of effective control of first efficiency and cycle stability, high capacity, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

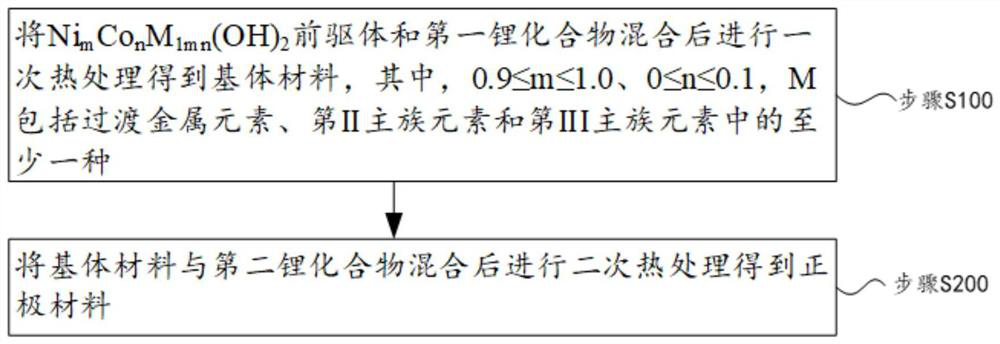

[0106] The application also provides a preparation method of positive electrode material, such as figure 1 As shown, it is a flow chart for the preparation of the positive electrode material of the present application, including the following steps:

[0107] Step S100, Ni m co n m 1-m-n (OH) 2 The precursor and the first lithium compound are mixed and subjected to a heat treatment to obtain a matrix material, wherein, 0.9≤m≤1.0, 0≤n≤0.1, M includes at least transition metal elements, II main group elements and III main group elements A sort of.

[0108] Step S200 , mixing the matrix material with the second lithium compound and performing a second heat treatment to obtain the positive electrode material.

[0109] This application is approved by Ni m co n m 1-m-n (OH) 2 The precursor and the first lithium compound are subjected to a heat treatment to realize the effective control of the lattice lithium in the matrix material and ensure that the material has a good laye...

Embodiment 1

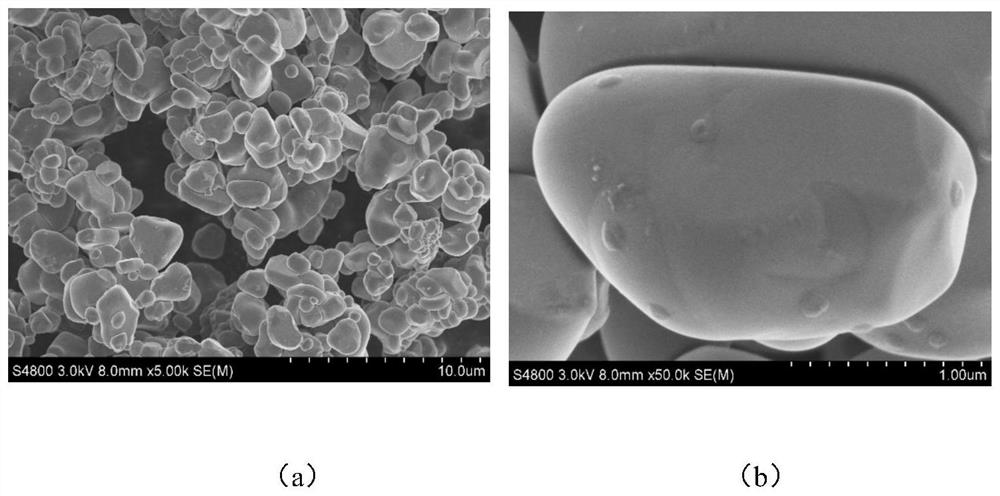

[0155] In this embodiment, the positive electrode material is prepared according to the following method:

[0156] (1) The precursor LiNi 0.94 co 0.055 mn 0.005 o 2 , Lithium hydroxide and tungsten oxide were added to the high mixer, and mixed at high speed for 30 minutes; the molar ratio of precursor and lithium salt was Li / A=1.07 (A=Ni, Co and Mn), and tungsten oxide was 0.94 co 0.055 mn 0.005 o 2 The mass proportion in the mixture is 0.05%, and then heat-treated at 800°C for 10 hours, and after crushing and pulverizing, the matrix material is obtained;

[0157] (2) Weigh a certain proportion of distilled water and base material, wash with water for 0.1h, carry out suction filtration and vacuum drying to the washed material to obtain material M2;

[0158] (3) According to the mass ratio of 1:0.01:0.01, the material M2, lithium hydroxide and tungsten oxide were respectively weighed and added into a high-mixer, and after mixing evenly, they were kept at 500° C. for 5 ho...

Embodiment 2

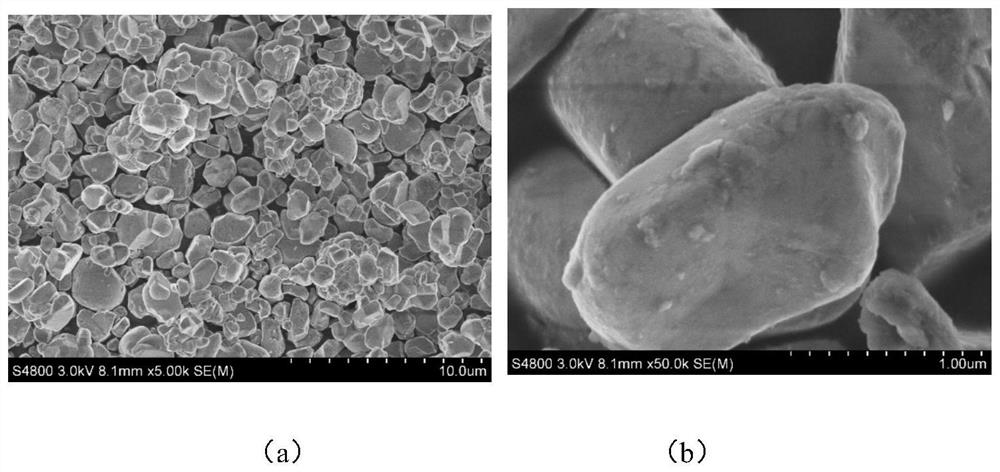

[0160] In this embodiment, the positive electrode material is prepared according to the following method:

[0161] (1) The precursor LiNi 0.94 co 0.055 mn 0.005 o 2 , lithium hydroxide and zirconium oxide were added to the high mixer, and mixed at high speed for 30 minutes; the molar ratio of precursor and lithium salt was Li / A=1.07 (A=Ni, Co and Mn), strontium hydroxide 0.94 co 0.055 mn 0.005 o 2 The mass proportion in the mixture is 0.15%, and then heat-treated at 700°C for 8 hours, and after crushing and pulverizing, the matrix material is obtained;

[0162] (2) Weigh a certain proportion of distilled water and base material, wash with water for 0.1h, carry out suction filtration and vacuum drying to the washed material to obtain material M2;

[0163] (3) According to the mass ratio of 1:0.002:0.01, the material M2, lithium hydroxide and tungsten oxide were respectively weighed and added into a high-mixer, and after mixing evenly, they were kept at 350° C. for 5 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com