Process for attaching cloth to special-shaped metal loudspeaker box

A special-shaped metal and speaker technology, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of low attachment efficiency and single fabric structure, and achieve the effects of good consistency, firm connection and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

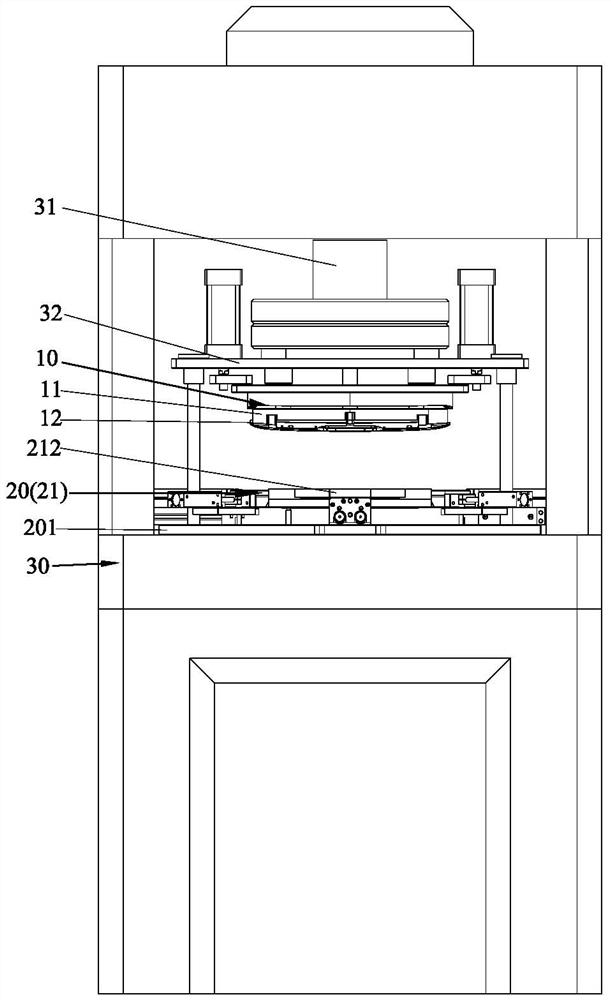

[0056] Please refer to Figure 1 to Figure 7 Shown, it has shown the concrete structure of preferred embodiment of the present invention, is a kind of special-shaped metal sound box shell cloth sticking process.

[0057] see figure 1 As shown, the special-shaped metal speaker shell cloth attachment process includes the following steps:

[0058] Step 1, cutting to obtain PU cloth 60 and metal sheet 70 whose size is suitable for the sound box shell 50;

[0059] Step 2, stamping the metal sheet 70 to produce a plurality of barbs 71; stamping the speaker shell 50 to produce a plurality of shrapnel 51;

[0060] Step 3, attach one side of the metal sheet 70 to the inner side of the PU cloth 60, and insert the barb 71 into the PU cloth 60 to complete the connection between the metal sheet 70 and the PU cloth 60;

[0061] Step 4, attaching a hot melt adhesive film 80 on the other side of the metal sheet 70 to form a semi-finished cloth 40;

[0062] Step 5. Place the semi-finished ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com