Cathode material, preparation method thereof and battery using cathode material

A technology of composite oxides and precursors, applied in the field of preparation, lithium-nickel-manganese-cobalt-fluorine composite oxide materials and their precursors, and lithium-ion secondary batteries, can solve the problem of poor cycle performance of positive electrode materials, Difficult to control and other problems, to achieve the effect of easy control of sedimentation ratio, good layered structure and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A preparation method of lithium-nickel-manganese-cobalt-fluorine composite oxide, which comprises:

[0029] (1) Add the mixed solution of nickel salt, cobalt salt and manganese salt and the precipitant solution containing fluorine ions into the reaction kettle for reaction and precipitation. After the reaction is completed, rinse the precipitated product with deionized water for 3 times, and suction filter , dried at 80°C for 2-12 hours to make a precursor;

[0030] (2) Mix the precursor and the lithium-containing compound at a ratio of 1:1 to 1.1, and sinter at high temperature in an oxygen-containing atmosphere.

[0031] The present invention may also include grinding and sieving the sintered product after high-temperature sintering.

[0032] The mixed solution of nickel salt, cobalt salt and manganese salt refers to a mixed solution in which nickel salt, cobalt salt and manganese salt are dissolved in deionized water in a certain proportion to form 2 mol / l.

[0033...

Embodiment 1

[0063] Be 1: 1: 1 by weighing manganese sulfate, nickel sulfate, cobalt sulfate and prepare 28L of the mixed solution of nickel salt, cobalt salt, manganese salt of 2mol / L; 20L of precipitant solution containing fluoride ion in concentrated ammonia water, where F - The concentration is 0.1mol / L, NH 3 The concentration is 1.2mol / L, and the pH is 11.5.

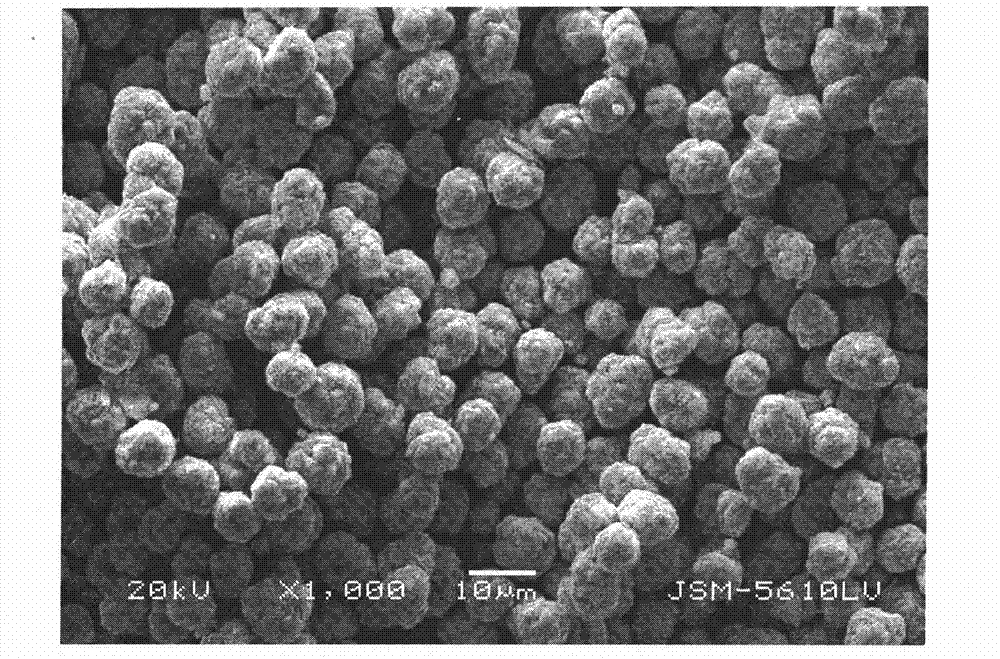

[0064] Add the mixed solution of nickel salt, cobalt salt and manganese salt and the precipitant solution into the reaction kettle, keep the stirring speed at 500 rpm, and feed nitrogen at a speed of 50 mL / min. Control the pH value at 11.5, react for 20 hours, release the reaction product, wash and dry. get the precursor.

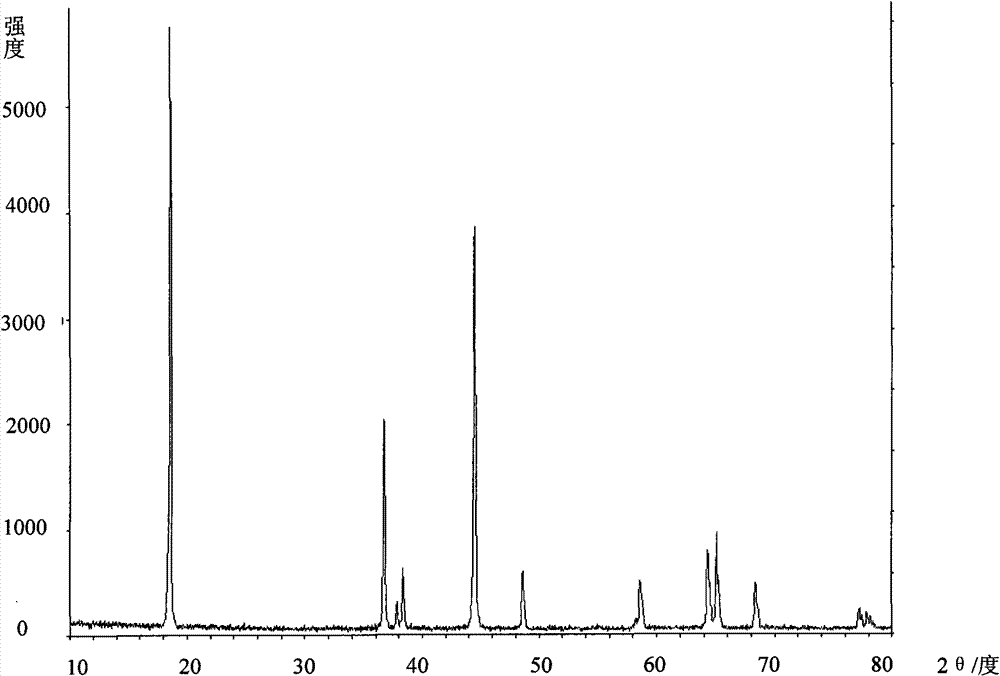

[0065] The precursor and lithium carbonate were mixed and sintered at a molar ratio of 1:1.05, kept at 650°C for 5 hours, then heated to 950°C for 20 hours, then slowly cooled to room temperature with the furnace temperature, taken out, ground and crushed for 200 Mesh sieve, the obtained lithium-nickel-ma...

Embodiment 2

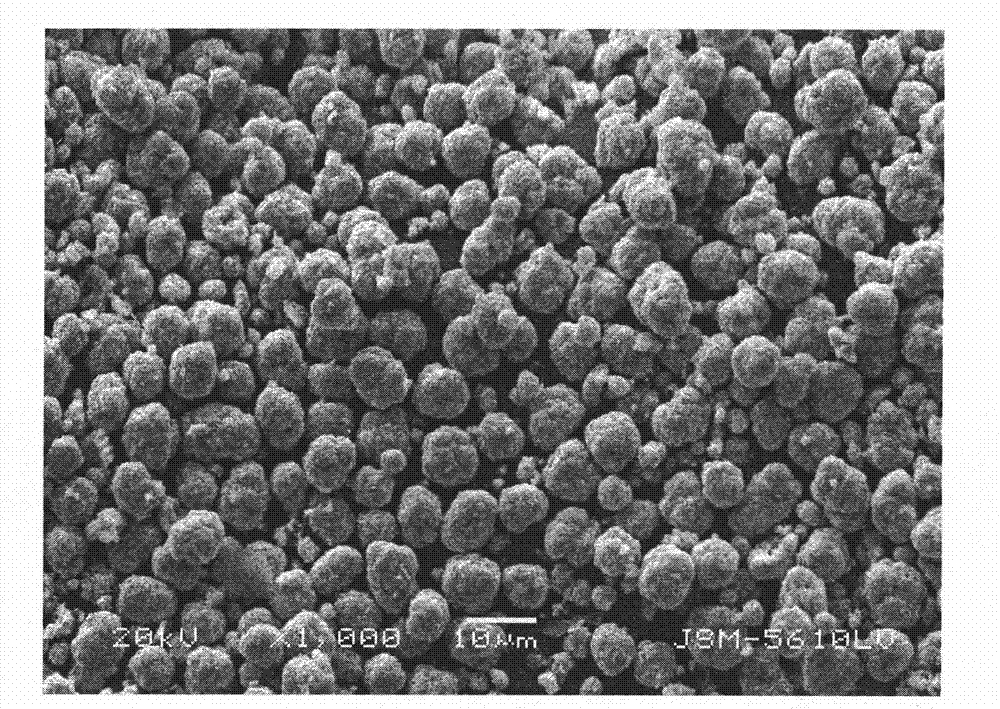

[0076] The difference from Example 1 is that the F in the precipitant containing fluoride ions - The concentration is 0.2mol / L. Others are the same as in Example 1, and the lithium-nickel-manganese-cobalt-fluorine composite oxide is prepared as G2. The battery is denoted as A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com