Novel functional ceramic membrane material and preparation method thereof

A technology of functional ceramics and membrane materials, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve problems such as insufficient adsorption capacity and water purification, insufficient ceramsite pores and specific surface area, and insufficient microbial affinity , to achieve the effects of improving pollutant treatment and microbial affinity, increasing pore and specific surface area, and enhancing adsorption and catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

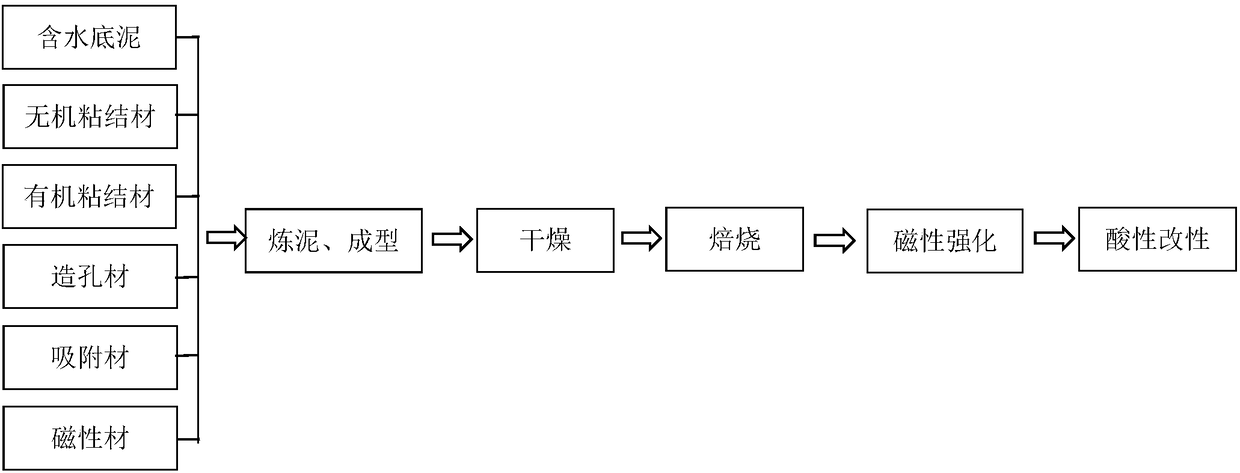

[0042] The preparation steps of the functional ceramic membrane material of the present invention include: a raw material preparation step; mud refining and extrusion molding steps; drying; high-temperature roasting; wherein, magnetic materials are added to the raw materials. The amount of magnetic material added is added according to different raw materials and needs, and its added amount can be between 0.1%-20% by weight of raw materials.

[0043] As a further improvement of the present invention, the high-temperature baked ceramic membrane material is placed in a static magnetic field, an alternating magnetic field, a pulsating magnetic field, and a pulsed magnetic field generator for magnetization treatment for more than 0.0001 second. The time of the magnetization treatment usually depends on the voltage of the magnetic field generator, the power of the magnetic field generator, the amount of magnetic material or its precursor added in the ceramic membrane material, and th...

preparation example 1

[0057] Step 1: Stir and mix the water-containing sediment, kaolin, carboxymethyl cellulose, cornstarch, reduced iron powder, and zeolite powder in a certain river course in Ma'anshan. The mixing ratio is shown in Table 2;

[0058] Step 2: Mud refining and extrusion molding;

[0059] Step 3: Dry at 80°C for 5 hours;

[0060] Step 4: Roasting at 1150°C for 5 hours under nitrogen protection;

[0061] Step 5: 0.01T pulsed magnetic field is strengthened for 0.1s;

[0062] Step 6: Soak in 1M sulfuric acid at 70° C. for 4 hours to obtain material A.

[0063] Table 2: Preparation parameters of material preparation examples and comparative examples

[0064]

preparation example 2

[0066] Material preparation example 1 same method:

[0067] Step 1: Stir and mix water-containing sediment, kaolin, carboxymethyl cellulose, corn starch, ferrous sulfate, and zeolite powder in a certain river course in Ma'anshan, and refer to Table 2 for the mixing ratio;

[0068] Step 2: Mud refining and extrusion molding;

[0069] Step 3: Dry at 80°C for 4 hours;

[0070] Step 4: Roasting at 1150° C. for 6 hours under nitrogen protection;

[0071] Step 5: The static magnetic field of 0.01T is strengthened for 1s;

[0072] Step 6: Soak in 1M sulfuric acid at 70°C for 4 hours to obtain material B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com