A kind of method that prepares hot-melt adhesive by lac waste slag glue and waste polyester

A technology of waste polyester and waste slag, which is applied in the direction of adhesives, etc., can solve the problems of long preparation process, waste of resources, and increased costs, and achieve the effects of reducing manufacturing costs, improving fluidity, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

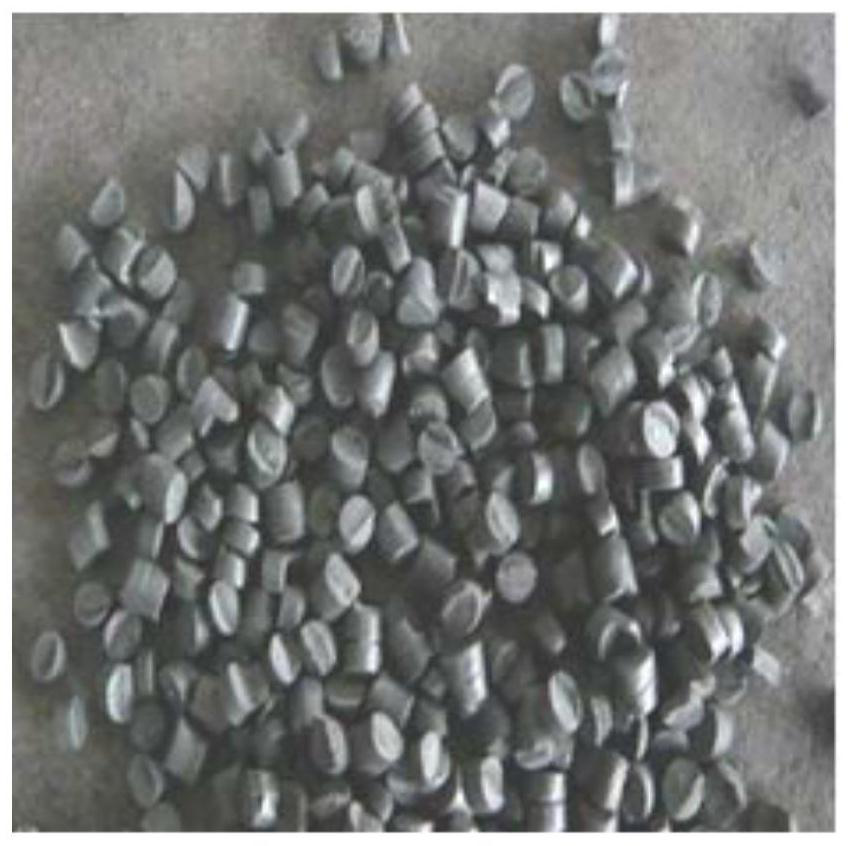

Image

Examples

Embodiment 1

[0059] Gum lac and discarding waste slag preparation polyester hot-melt adhesive, a raw material which comprises: dehydrating waste slag shellac gum 20g, waste PET 100g, 20g of ethylene glycol (ethylene glycol / polyester waste is 0.6 molar ratio), zinc acetate 0.7g, glycidyl ester of polymerized rosin, 10g, glycidyl ester of rosin 15g, tackifying resins 13.2g [(3) ~ (4) step 8% of the total feeding amount], light calcium carbonate 13.2g [(3) - step (4) the total feeding amount of 8%], antioxidant 1010 0.33g [(3) ~ (4) step total feeding amount of 0.2%]. Preparation of Hot Melt specific steps are as follows:

[0060] Preparation of (1) dehydration of waste slag shellac gum

[0061] Extracted from the gum or shellac particles shellac gum production line made aleuritic acid residue discarded gum shellac, a vacuum oven at 85 ℃ 8h remove water and dried in vacuo to prepare a dehydrated waste slag shellac gum, referred to as WS. Black viscous liquid at room temperature (melting point l...

Embodiment 2

[0074] Gum lac and discarding waste slag preparation polyester hot-melt adhesive, a raw material which comprises: dehydrating waste slag shellac gum 50g, waste PET 100g, 30g of ethylene glycol (ethylene glycol / polyester waste is 0.9 molar ratio), manganese acetate 1.2g, 13g glycidyl ester of polymerized rosin, rosin glycidyl 7g, tackifying resins 20.1g [(3) ~ (4) step total feeding amount of 10%], light calcium carbonate 20.1g [(3) - step (4) the total feeding amount of 10%], antioxidant 0.80g [(3) ~ (4) step total feeding amount of 0.4%].

[0075] Specifically Step 1, except that the same Example:

[0076] Step (1) was dried in vacuo at 78 deg.] C 12h;

[0077] Step (4) the grafting of CPC / coupling reaction temperature was 180 ℃, the reaction time is 2H;

[0078] Step (5) The mixture was poured into hot water of 40 ℃.

[0079] The hot melt adhesive was measured softening point of 112 ℃, MFR of 31g / 10min, the shear strength of 5.1MPa.

Embodiment 3

[0081] Gum lac and discarding waste slag preparation polyester hot-melt adhesive, a raw material which comprises: dehydrating waste slag shellac gum 70g, waste PET 100g, 4Og glycol (ethylene glycol / polyester waste is 1.2 molar ratio), zinc acetate 1.0g, glycidyl ester of polymerized rosin, 16g, glycidyl ester of rosin 10g, tackifying resins 28.4g [(3) ~ (4) step total feeding amount of 12%], light calcium carbonate 28.4g [(3) - step (4) the total feeding amount of 12%], antioxidant 1.42g [(3) ~ (4) step total feeding amount of 0.6%].

[0082] Specifically Step 1, except that the same Example:

[0083] Step (1) was dried in vacuo for 16h 70 ℃;

[0084] Step (4) the grafting of CPC / coupling reaction temperature was 170 ℃, the reaction time is 3H;

[0085] Step (5) The mixture was poured into hot water of 50 deg.] C.

[0086] The hot melt adhesive was measured softening point of 106 ℃, MFR of 35g / 10min, the shear strength of 5.6MPa.

[0087] Wherein the step of black viscous liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com