Manufacturing process of polycrystalline diamond machining tool

A polycrystalline diamond and tool processing technology, which is applied in the field of tool processing, can solve the problems of weak bonding between diamond coating and cemented carbide substrate, large difference in thermal expansion coefficient between coating and substrate, and inability to achieve high precision and long life. , to achieve the effect of good dimensional stability, low scrap rate and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

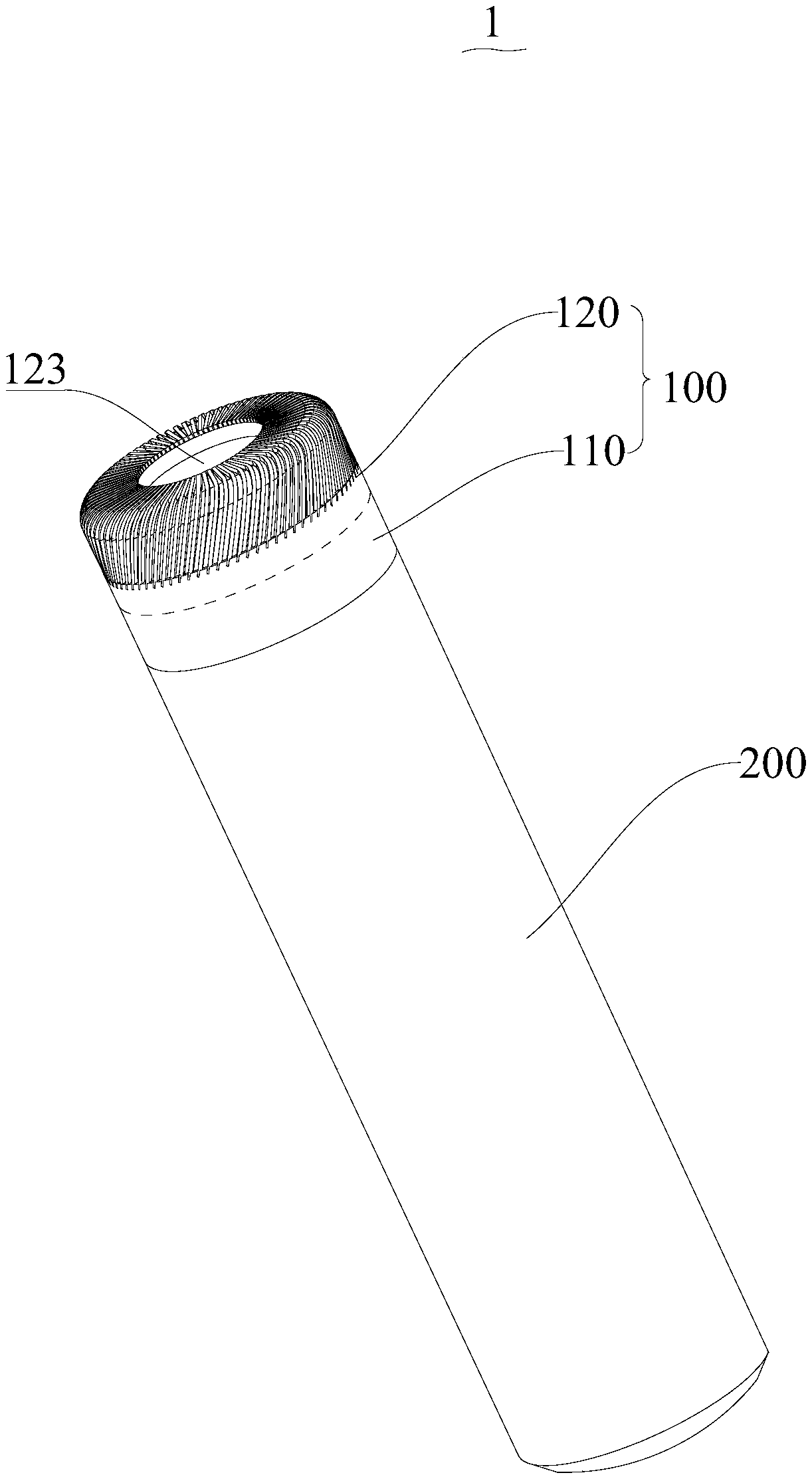

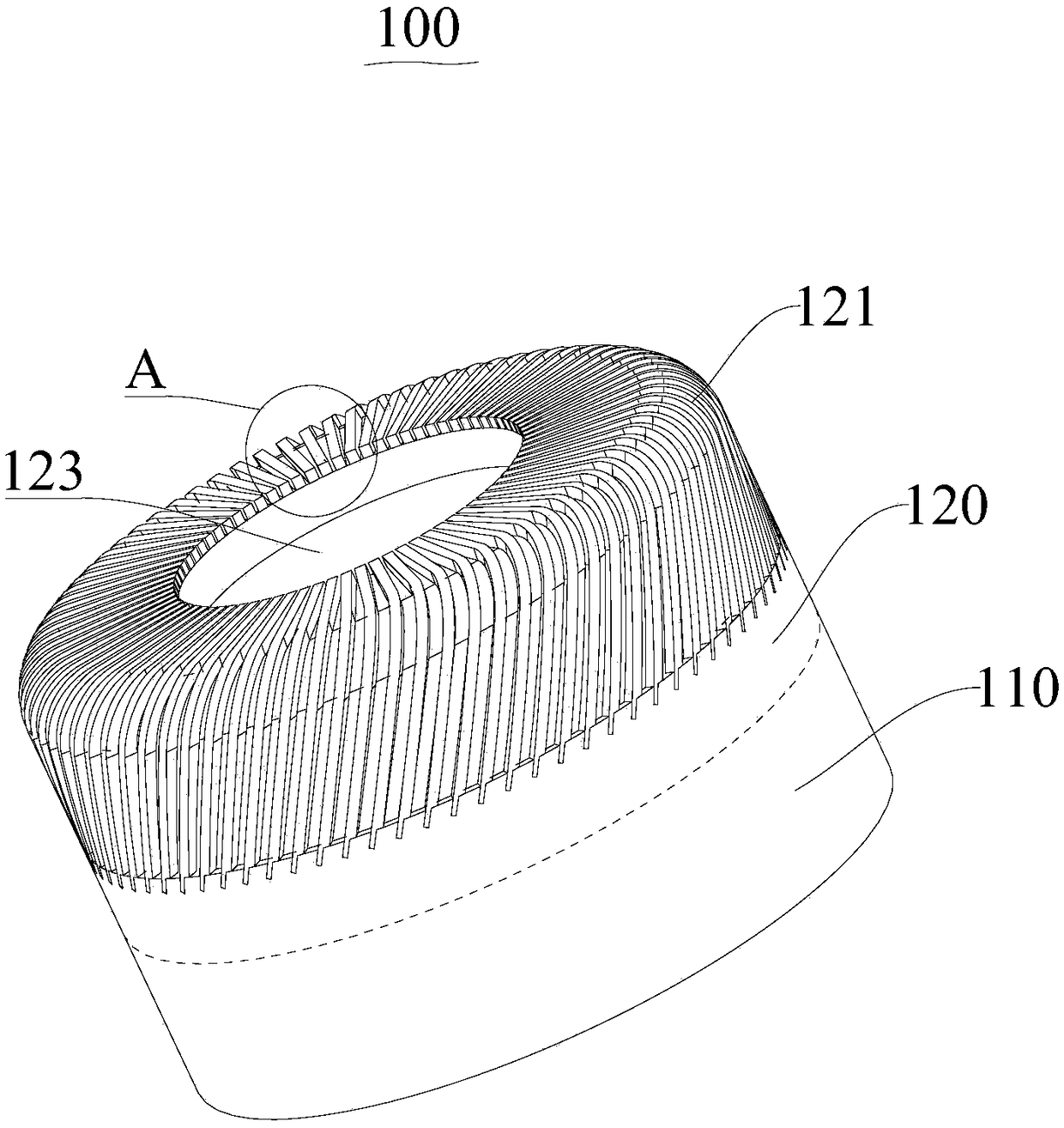

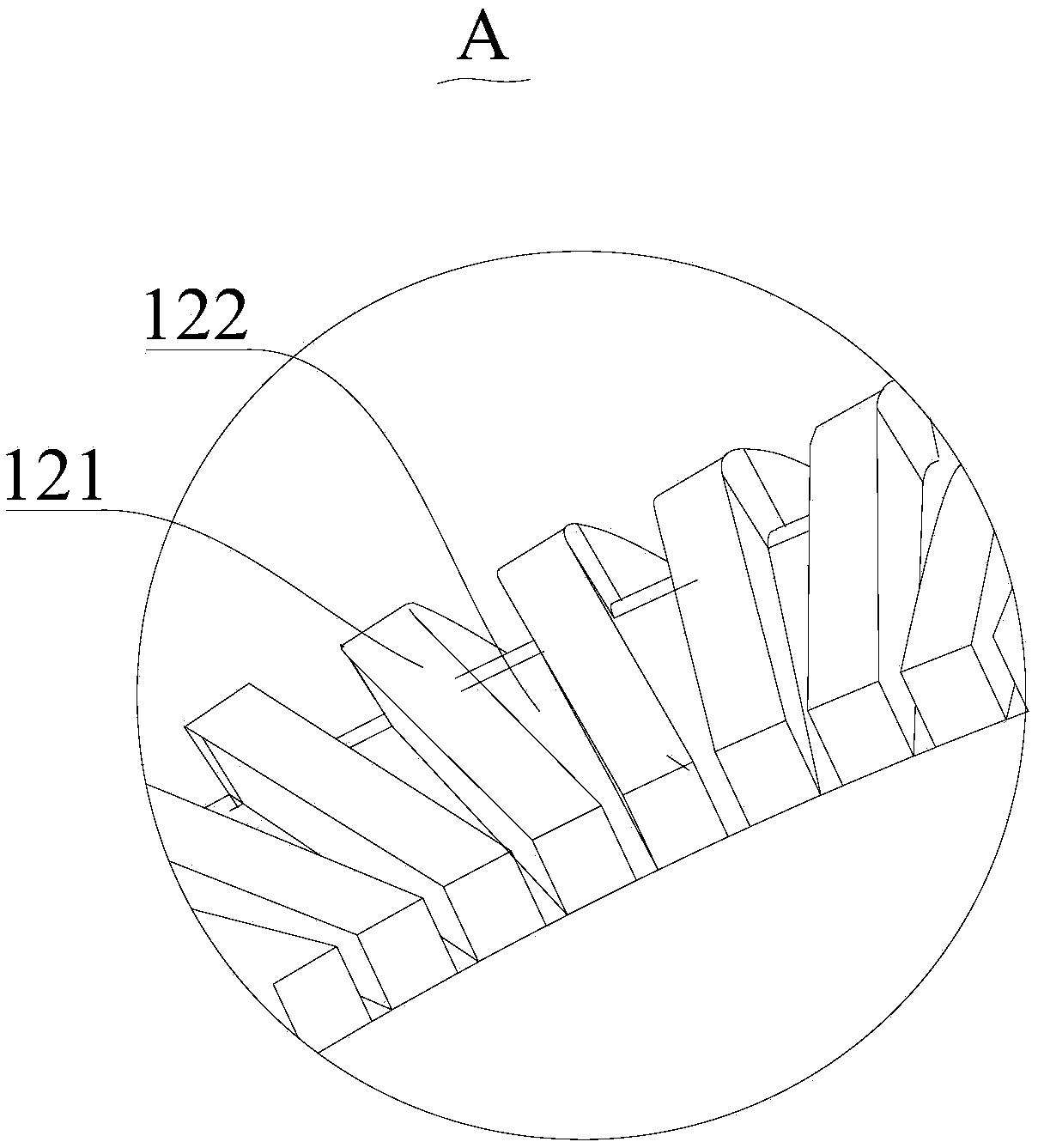

[0068] A manufacturing process of a polycrystalline diamond processing tool 1 includes the following steps:

[0069] (1) Provide 200 blanks of rigid tool holder and 100 blanks of polycrystalline diamond tool head. The 200 blanks of tool holder are made of tungsten carbide-based cemented carbide; the 100 blanks of polycrystalline diamond tool head are made by combining the base layer 110 and The polycrystalline diamond layer 120 is pressed and sintered. The base layer 110 is made of tungsten carbide-based cemented carbide. The polycrystalline diamond layer 120 is made of a composite of synthetic diamond powder and functional metal powder. The particle size of the synthetic diamond powder It is 300μm, and the functional metal powder is a mixed powder of cobalt powder, nickel powder, chromium powder and tungsten carbide powder in a mass ratio of 0.5:3:3:3.5. The mass percentage of cobalt in tungsten carbide-based cemented carbide does not exceed 12% .

[0070] (2) First, polish the w...

Embodiment 2

[0079] A manufacturing process of a polycrystalline diamond processing tool 1 includes the following steps:

[0080] (1) Provide 200 blanks of rigid tool holder and 100 blanks of polycrystalline diamond tool head. The 200 blanks of tool holder are made of tungsten carbide-based cemented carbide; the 100 blanks of polycrystalline diamond tool head are made by combining the base layer 110 and The polycrystalline diamond layer 120 is pressed and sintered. The base layer 110 is made of tungsten carbide-based cemented carbide. The polycrystalline diamond layer 120 is made of a composite of synthetic diamond powder and functional metal powder. The particle size of the synthetic diamond powder It is 400μm, the functional metal powder is a mixed powder of cobalt powder, nickel powder, chromium powder and tungsten carbide powder in a mass ratio of 0.5:3:3:3.5. The mass percentage of cobalt in tungsten carbide-based cemented carbide does not exceed 12% .

[0081] (2) First, polish the weldi...

Embodiment 3

[0090] A manufacturing process of a polycrystalline diamond processing tool 1 includes the following steps:

[0091] (1) Provide 200 blanks of rigid tool holder and 100 blanks of polycrystalline diamond tool head. The 200 blanks of tool holder are made of tungsten carbide-based cemented carbide; the 100 blanks of polycrystalline diamond tool head are made by combining the base layer 110 and The polycrystalline diamond layer 120 is pressed and sintered. The base layer 110 is made of tungsten carbide-based cemented carbide. The polycrystalline diamond layer 120 is made of a composite of synthetic diamond powder and functional metal powder. The particle size of the synthetic diamond powder is It is 300μm, and the functional metal powder is a mixed powder of cobalt powder, nickel powder, chromium powder and tungsten carbide powder in a mass ratio of 0.5:3:3:3.5. The mass percentage of cobalt in tungsten carbide-based cemented carbide does not exceed 12% .

[0092] (2) First, polish th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com