Machining tool of polycrystalline diamond tool bit

A technology of polycrystalline diamond and tool processing, which is applied in the direction of stone processing tools, metal processing equipment, stone processing equipment, etc., and can solve the problem of coating failure, inability to achieve high precision and long life, and non-existence of bonding force of diamond coating tools, etc. problem, to achieve the effect of a wide range of industrial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

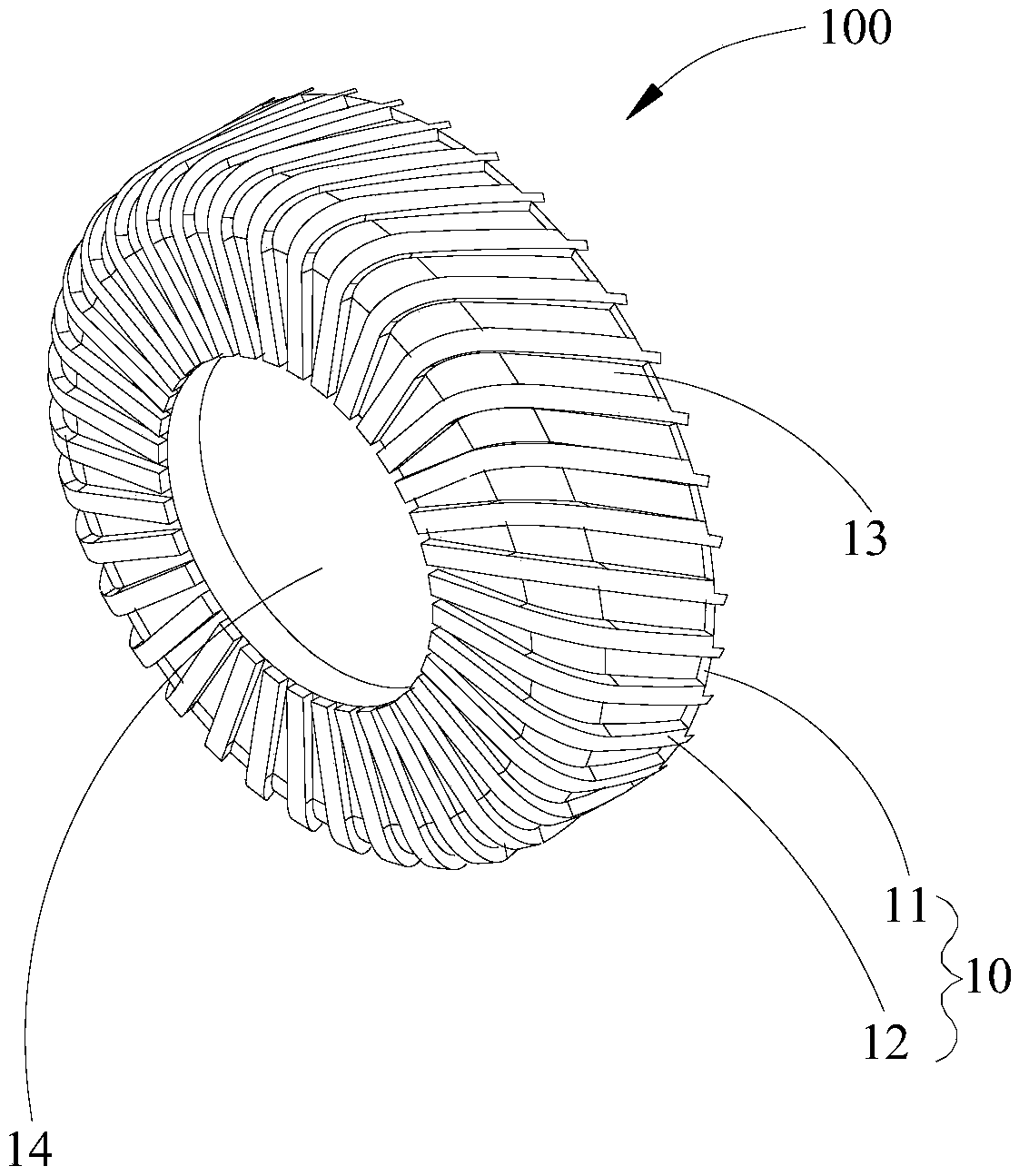

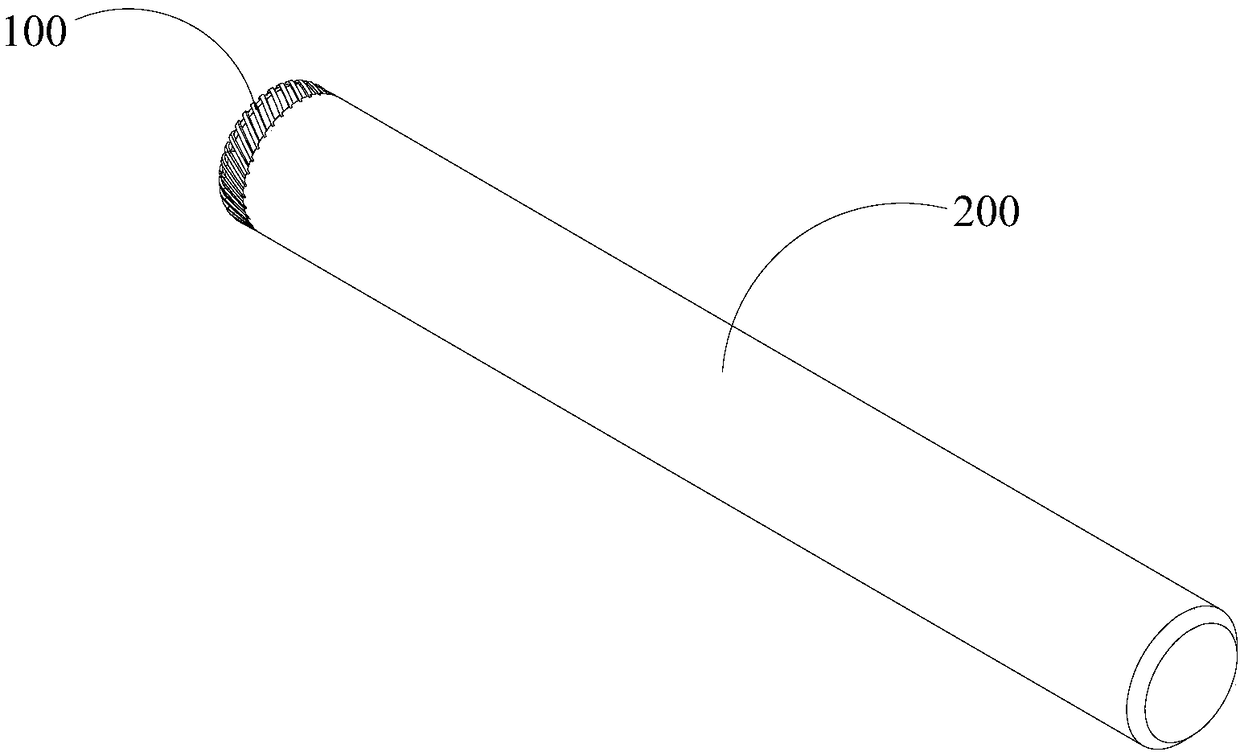

[0041]The present invention provides a processing tool with a polycrystalline diamond cutter head 100, which includes a cutter head 100 and a handle 200 connected to the cutter head 100. The cutter head 100 includes a base layer and a polycrystalline diamond covering the base layer. A crystalline diamond cutting layer 10, the polycrystalline diamond cutting layer 10 includes a cutting body 11 and 32-36 cutting edges 12 evenly distributed in a ring on the cutting body 11, and chip removal grooves are formed between adjacent cutting edges 12 13. The cutter head 100 and the cutter handle 200 are cylinders.

[0042] As mentioned above, the end of the base layer away from the polycrystalline diamond cutting layer 10 and the handle 200 are welded to the end of the handle 200 by welding to realize welding and fixing, so that the cutter head 100 and the handle 200 form an integral structure. It should be noted that the polycrystalline diamond cutting layer 10 is formed by molding and ...

Embodiment 2

[0064] A kind of polycrystalline diamond cutter head processing tool, comprising: a cutter head 100 and a handle 200 connected to the cutter head 100, the cutter head 100 includes a base layer and a polycrystalline diamond cutting layer 10 covering the base layer , the polycrystalline diamond cutting layer includes a cutting body 11 and 32-36 cutting edges 12 uniformly distributed on the cutting body in a ring shape.

[0065] Specifically, there may be 36 cutting edges 12 .

[0066] The base layer is made of tungsten carbide-based hard alloy material, and the cutting layer 10 is made of a composite of artificial diamond micropowder and functional metal powder, wherein the particle size of the artificial diamond micropowder is 360 μm, and the functional metal powder is cobalt powder, nickel powder, Chromium powder and tungsten carbide powder are mixed powders with a mass ratio of 0.5:3:3:3.5, and the mass percentage of cobalt in tungsten carbide-based cemented carbide does not ...

Embodiment 3

[0074] A kind of polycrystalline diamond cutter head processing tool, comprising: a cutter head 100 and a handle 200 connected to the cutter head 100, the cutter head 100 includes a base layer and a polycrystalline diamond cutting layer 10 covering the base layer , the polycrystalline diamond cutting layer includes a cutting body 11 and 32-36 cutting edges 12 uniformly distributed on the cutting body in a ring shape. Specifically, there may be 36 cutting edges 12 .

[0075] The base layer is made of tungsten carbide-based hard alloy material, and the cutting layer 10 is made of a composite of artificial diamond micropowder and functional metal powder, wherein the particle size of the artificial diamond micropowder is 380 μm, and the functional metal powder is cobalt powder, nickel powder, Chromium powder and tungsten carbide powder are mixed powders with a mass ratio of 0.5:3:3:3.5, and the mass percentage of cobalt in tungsten carbide-based cemented carbide does not exceed 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com