Mechanical equipment maloperation preventing system and control method

A kind of mechanical equipment, anti-misoperation technology, applied in the direction of digital control, program control, electrical program control, etc., can solve the problems of endangering the safety of mechanical equipment and low reliability of control circuits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

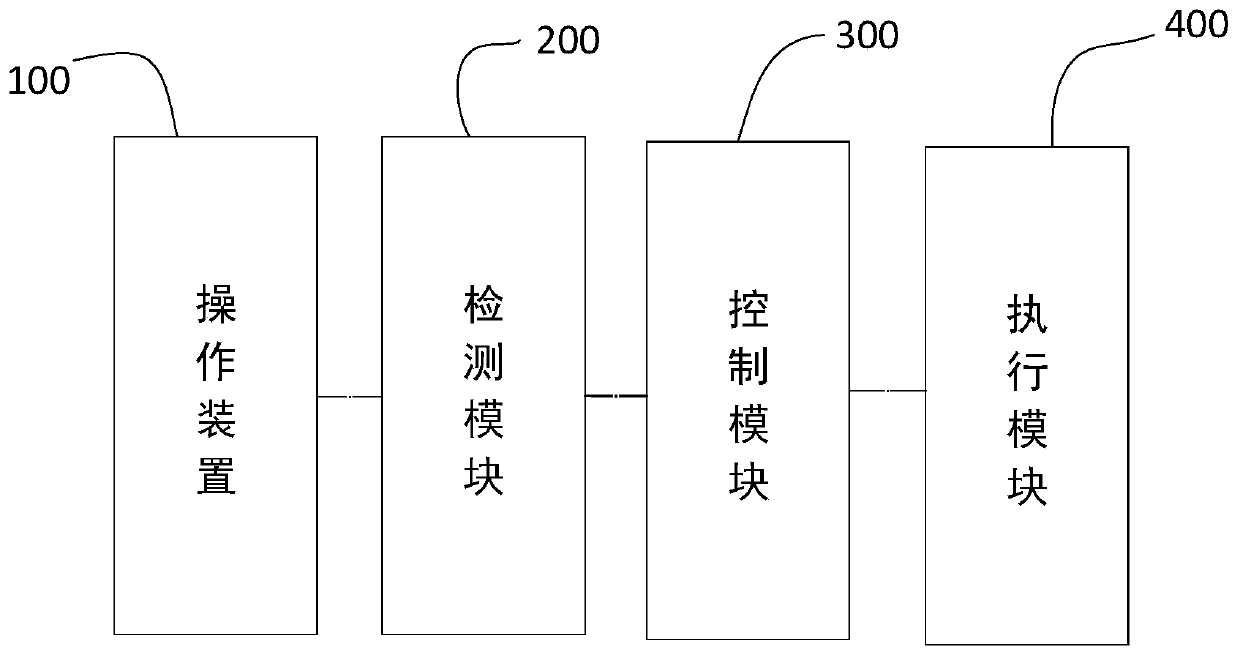

[0045] see figure 1, the mechanical equipment anti-maloperation system of this embodiment includes an operating device 100, a detection module 200, a control module 300, and an execution module 400; the operating device 100 is used for operating and controlling the mechanical equipment; Connected, used to detect the position status information of the operating device 100; the control module 300 is electrically connected to the detection module 200, used to obtain the position status information, and judge whether the position status information is abnormal; the execution module 400 is electrically connected to the control module 300, when judging As a result, when the position status information is abnormal, the control module 300 is further configured to send a control instruction to the execution module 400, and the execution module 400 controls the mechanical equipment after receiving the control instruction.

[0046] There are many kinds of mechanical equipment. When the m...

Embodiment 2

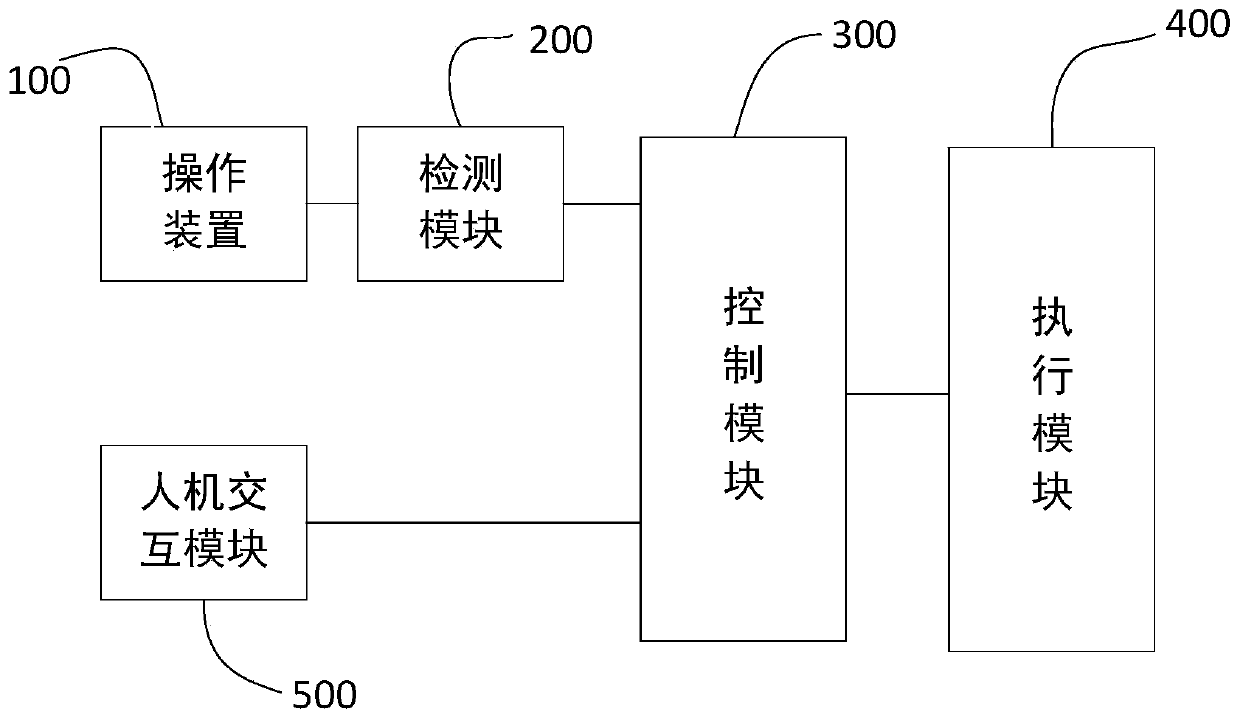

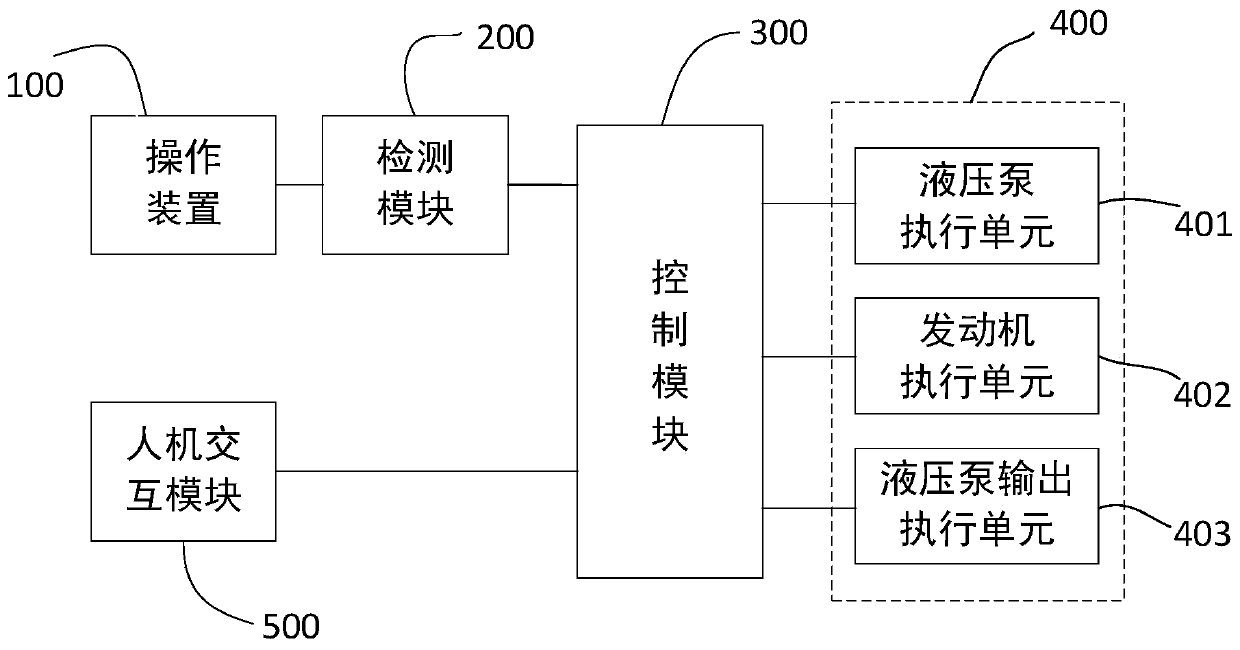

[0059] see figure 2 , The anti-misoperation system of mechanical equipment provided in this embodiment is based on the first embodiment and the following improvements have been made to the design of some components, and other structures have not been changed, and the structural design of the first embodiment can be referred to.

[0060] Specifically, the mechanical equipment anti-maloperation system of this embodiment also includes a human-computer interaction module 500, which is electrically connected to the control module 300 to display information sent by the control module 300, and to control the control module 300. control.

[0061] In the mechanical equipment anti-maloperation system of this embodiment, the operating device 100 is used to operate and control the mechanical equipment. When the mechanical equipment needs to be used, the operator enters the cab of the mechanical equipment, starts the mechanical equipment, that is, powers on the mechanical equipment. Afte...

Embodiment 3

[0064] see Figure 4 , this embodiment also provides a mechanical equipment anti-maloperation control method, including:

[0065] S100: start the mechanical equipment;

[0066] When the mechanical equipment needs to be used, the operator enters the cab of the mechanical equipment, starts the engine of the mechanical equipment, and powers up the mechanical equipment.

[0067] S200: Obtain the position status information of the operating device 100 of the mechanical equipment;

[0068] The detection module 200 electrically connected to the operating device 100 begins to detect the position status information of the operating device 100. When in the off state, the control module 300 determines that the position status of the operating device 100 is normal, and the control module 300 turns off the detection module 200, so that the detection module 200 stops detecting the position status information of the operating device 100, and the device operates normally.

[0069] S300: Ju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com