Cross-linkable fluororesin modified prepreg and thermosetting copper-clad plate prepared from same

A technology of cross-linked fluororesin and prepreg, which is applied in the field of communication materials to achieve broad application prospects, a good industrial production basis, and the effect of low thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

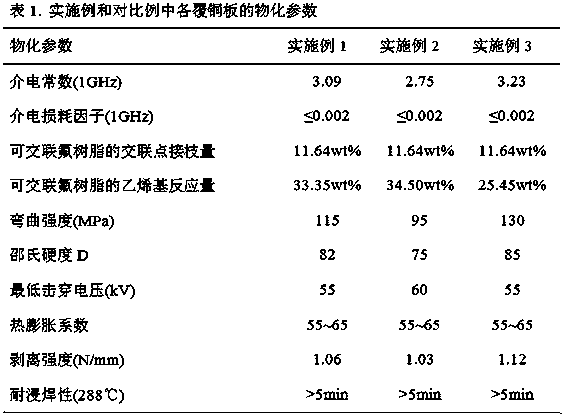

Examples

Embodiment 1

[0028]Add 9 parts of divinylbenzene and 0.28 parts of bipyridine to 85 parts of tetrafluoroethylene-perfluoroalkoxy vinyl ether copolymer emulsion (DuPont Teflon® PFAD 335D, solid content 60%), stir well, and repeat freezing -Degassing-dissolving step three times to remove the oxygen in the system; then, add 0.45 parts of CuBr to the above system, repeat the freezing-degassing-dissolving step three times in the same way to further remove the oxygen in the system, at 85 ℃, vigorously stir After reacting for 32 hours, stir-dialysis to obtain a dispersion of divinylbenzene grafted PFA; then add 5 parts of SiO 2 (Xinyi Hongrun), 20 parts of flame retardant magnesium hydroxide (USA Albemarle MAGNIFIN H-5), 60 parts of TiO 2 (Tianjin Zhongzheng Huamei Technology), 0.65 parts of silane coupling agent KH550 (Nanjing Shuguang Chemical General Factory) and 0.24 parts of azobisisobutylamidine hydrochloride (Runxing Optoelectronics V-50), stir evenly at 20°C and tighten Then add 150 part...

Embodiment 2

[0030] The preparation method of the dispersion and the compound paste of divinylbenzene grafted PFA is the same as in Example 1; the compound paste is scraped into a film with a thickness of about 0.29 mm on a clean glass plate, and the After baking for 2 minutes, continue to bake at 210°C for 20 minutes. After it naturally drops to room temperature, peel off the film from the glass sheet to obtain a semi-cured dielectric sheet; take 2 sheets of the semi-cured dielectric sheet, 1 sheet of PTFE film and 2 pieces of loz copper foil, at a pressure of 120~150kg / cm 2 , and laminated for 8 hours at a temperature of 330° C. to obtain a fluororesin-modified thermosetting polybutadiene-based copper clad laminate.

Embodiment 3

[0032] The dispersion liquid of divinylbenzene grafted PFA is identical with embodiment 1; Then add 5 parts of SiO 2 (Xinyi Hongrun), 20 parts of flame retardant magnesium hydroxide (USA Albemarle MAGNIFIN H-5), 60 parts of TiO 2 (Tianjin Zhongzheng Huamei Technology), 0.65 parts of silane coupling agent KH550 (Nanjing Shuguang Chemical General Factory) and 0.24 parts of azobisisobutylamidine hydrochloride (Runxing Optoelectronics V-50), stir evenly at 20°C and tighten Then add 150 parts of DMF solution (Sabic SA9000) of 45wt% vinyl-terminated polyphenylene ether modified and stir vigorously evenly, wait until it is flocculated and precipitated until white sticky precipitate no longer appears, then pour off the solvent to obtain a composite paste; Scrape the composite paste on a clean stainless steel plate to form a film with a thickness of about 0.81mm, bake at 70°C for 5 minutes, and then continue to bake at 230°C for 35 minutes, and wait for it to cool down to room temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com