Resin composite film including cellulose microfiber layer

A technology of resin composite and microfiber, which is applied in the direction of polymer diaphragm, synthetic resin layered products, diaphragm structure, etc., which can solve the problems of difficulty in application and small fiber diameter control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0248] As a method for preparing a slurry for papermaking or coating, there are, for example, the following methods: (1) Mixing and dispersing a pre-prepared compound containing additives into a cellulose fine fiber slurry to prepare a papermaking slurry ; (2) While stirring the cellulose microfiber slurry, add various additives one by one. It should be noted that, in the case of adding a plurality of additives, in a system in which the additives aggregate each other (for example, a system in which a cationic polymer and an anionic polymer form an ionic complex), depending on the order of addition, there are Possibility of changes in dispersion state and zeta potential of papermaking slurry. However, the order and amount of addition are not particularly limited, and it is preferable to add by a method that can obtain the desired dispersion state and sheet properties of the papermaking slurry.

[0249] Examples of the stirring device for uniformly mixing and dispersing the abo...

Embodiment

[0395] Hereinafter, the present invention will be described in more detail using examples and comparative examples, but the present invention is not limited by these examples.

Embodiment approach I

[0397] "Measurement and Evaluation Methods of Physical Properties of Cellulose Fiber Sheets"

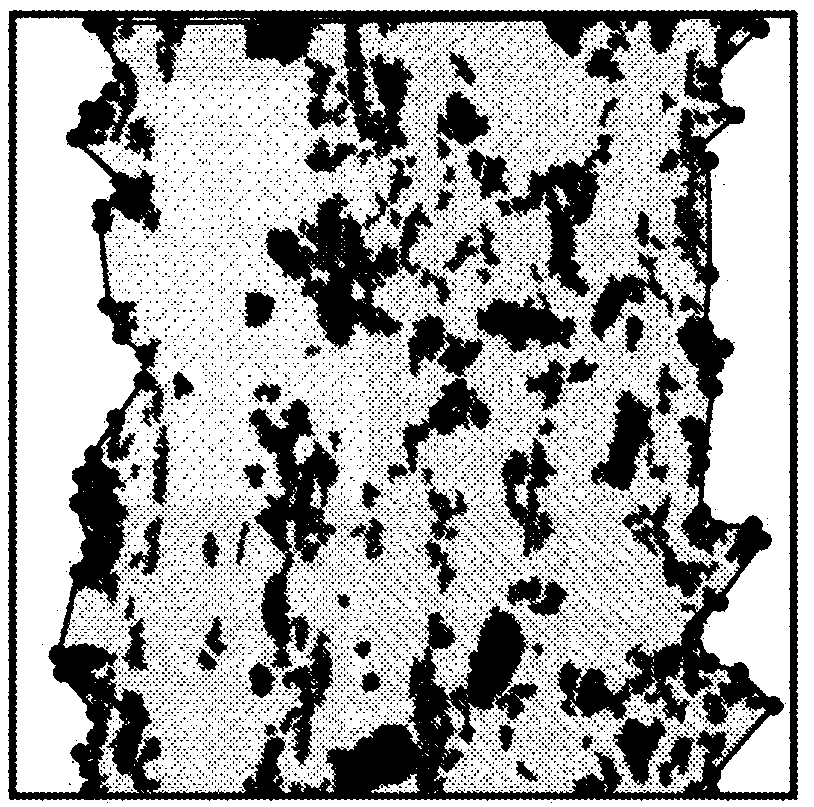

[0398]

[0399] In the fiber sheet, observation by a scanning electron microscope (SEM) was performed at 10 random positions from the surface of the cellulose fine fiber at a magnification corresponding to 1000 to 100000 times depending on the fiber diameter of the fine fiber. For the obtained SEM image, lines were drawn horizontally and vertically with respect to the screen, and the fiber diameters of fibers intersecting the lines were actually measured from the enlarged image, and the number of intersecting fibers and the fiber diameter of each fiber were counted. Thus, for each image, the number-average fiber diameter was calculated using the measurement results of the vertical and horizontal 2 series. Furthermore, the number-average fiber diameter was similarly calculated for the other two extracted SEM images, and the results for a total of 10 images were averaged.

[0400] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Secondary particle size | aaaaa | aaaaa |

| Average fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com