DoubLe-face tearabLe fabric for medicaL adhesive tape and processing method of fabric

A processing method and fabric technology, applied in the processing of textile materials, processing textile material carriers, liquid/gas/steam textile material processing, etc., can solve problems such as fuzzing and inconvenience, achieve reduction in fiber strength, simple operation, and convenient use and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

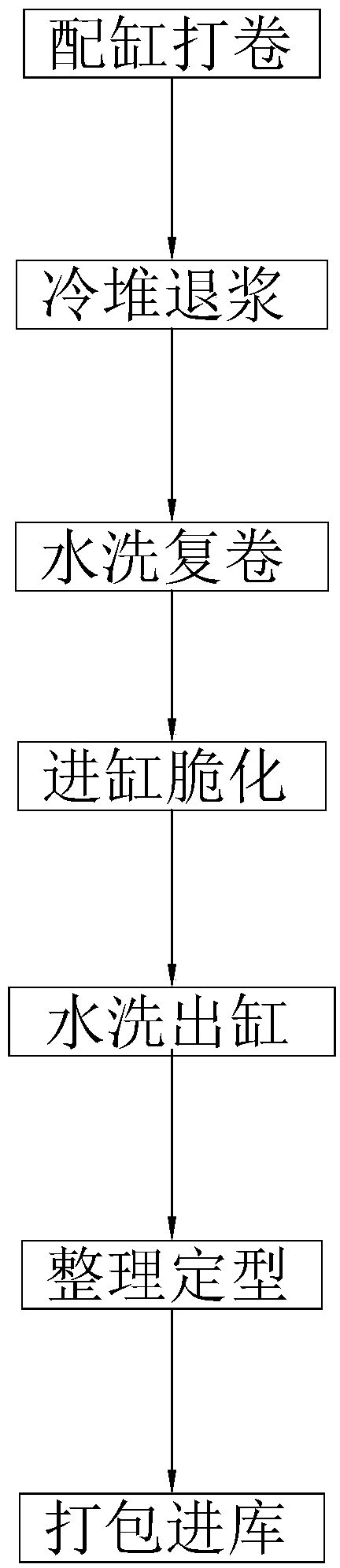

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: A double-sided tearable fabric for medical adhesive tape, including a fabric body formed by interlacing warp yarns and weft yarns, both warp yarns and weft yarns are made of polyester modified fibers. Among them, ordinary polyester fiber is made from purified terephthalic acid (PTA) or dimethyl terephthalate (DMT) and ethylene glycol (MEG) through esterification or transesterification and polycondensation reactions. Fiber polymer - polyethylene terephthalate (PET), fiber made by spinning and post-processing. It has the characteristics of strong and durable, good elasticity, not easy to deform, corrosion resistance, insulation, crisp, easy to wash and dry, and not easy to fluff.

[0036]In order to properly weaken the binding force between fiber molecules and reduce the fiber strength, in addition, the warp and weft yarns are all 100D polyester modified fibers. It is obtained by modifying the body and the fourth monomer. In addition, the third monomer ado...

Embodiment 2

[0039] Embodiment 2: A double-sided tearable fabric for medical adhesive tape, the difference from Embodiment 1 is that the third monomer is sodium terephthalic acid sulfonate, such as 2-sulfonic acid terephthalic acid Monosodium salt, which has the molecular formula C 8 h 5 NaO 7 S, its molecular formula contains 2 carboxyl groups; when added in the polymerization reaction, the hydrophilic group on the fiber can be increased at this time to increase the moisture regain of the fiber, thereby weakening the bonding force between the fiber molecules and making the crystallization more loose , the fiber strength is further reduced. And the fourth monomer is polyethylene glycol, its chemical formula is HO(CH 2 CH 2 O) n H, it not only has good water solubility, but also has good compatibility with many organic components; it also has excellent lubricity, moisture retention, dispersibility, adhesive, antistatic agent and softener.

Embodiment 3

[0040] Embodiment 3: a double-sided tearable fabric for medical adhesive tape, the difference from embodiment 1 is: the third monomer is sodium salt of isophthalic acid sulfonate, such as 5-thioisophthalic acid Monosodium, which has the molecular formula C 8 h 5 NaO 7 S, its molecular formula contains 2 carboxyl groups; when added in the polymerization reaction, the hydrophilic group on the fiber can be increased at this time to increase the moisture regain of the fiber, thereby weakening the bonding force between the fiber molecules and making the crystallization more loose , the fiber strength is further reduced. The fourth monomer is 1,4-dimethylolcyclohexane, 1,4-dimethylolcyclohexane, also known as bis(hydroxymethyl)cyclohexane, which is composed of dimethyl terephthalate The methanol solution of the ester (or ethylene glycol terephthalate) is produced by hydrogenation reduction under pressure and can be used as a lubricant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com