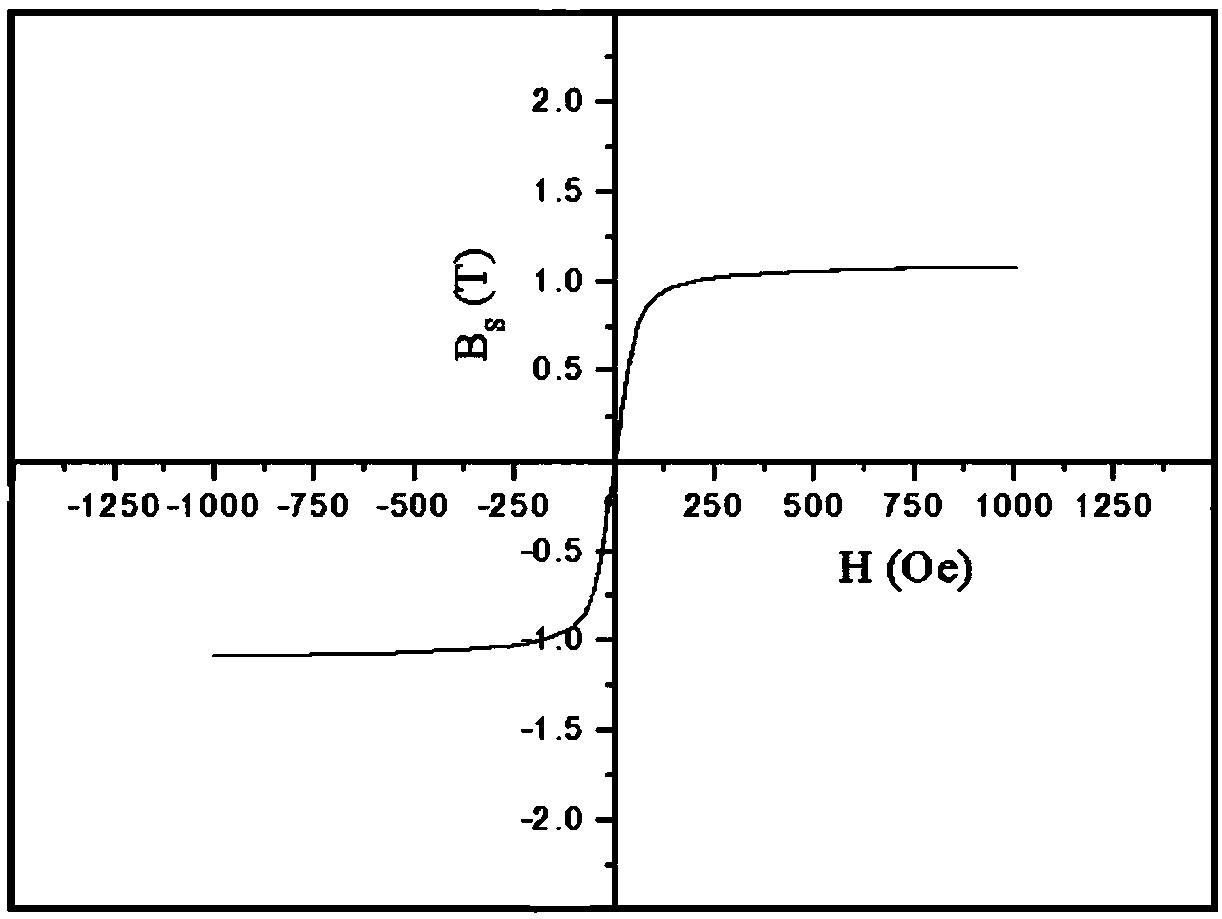

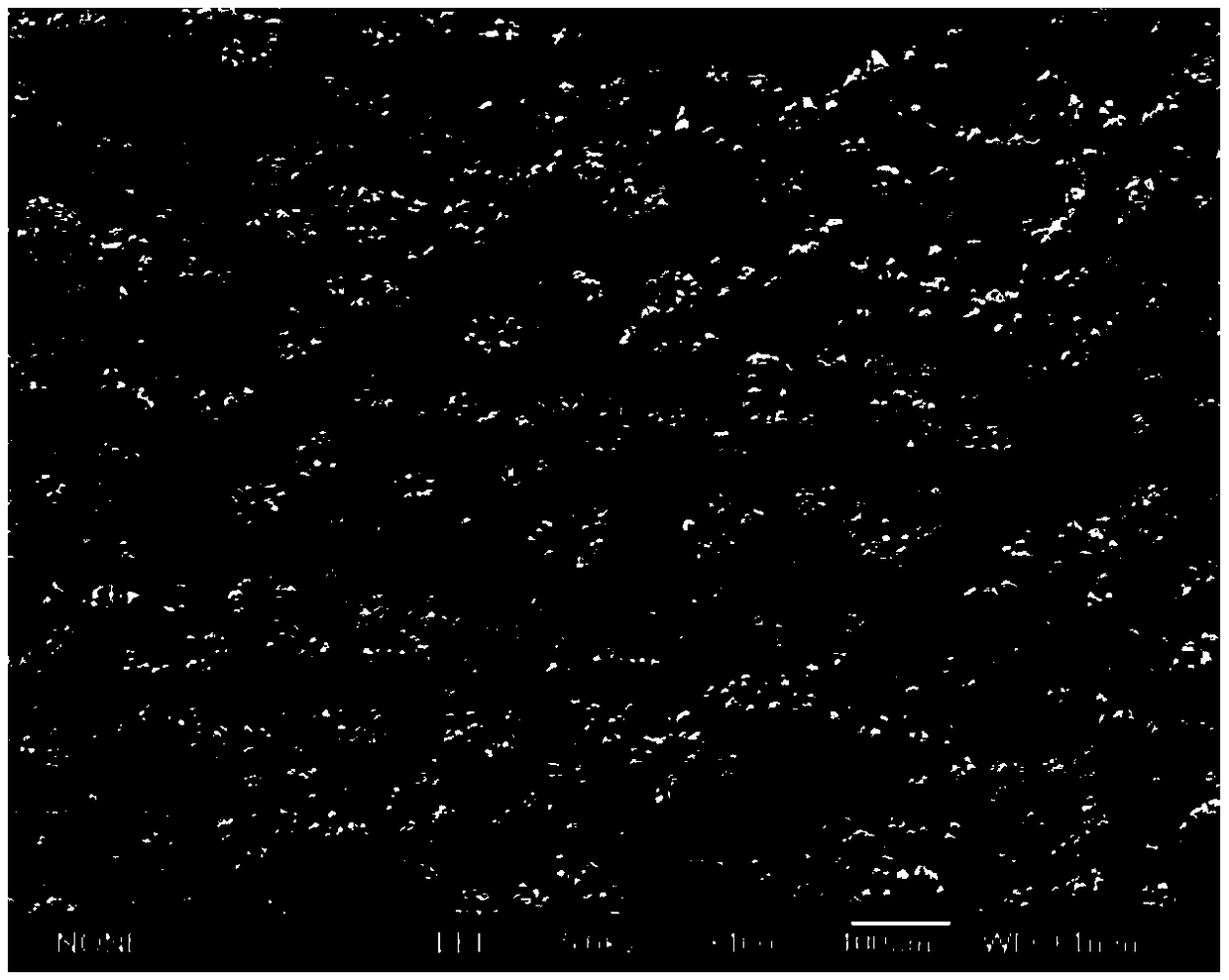

Technology for preparing coarsened nickel foil with electrodeposition method

An electrodeposition method and electrodeposition technology, which are applied in the field of nickel alloys, can solve the problems of consuming a lot of manpower and material resources, poor controllability of roughness, etc., and achieve the effect of uniform surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The specific steps of the process for preparing roughened nickel foil by electrodeposition in this embodiment are as follows:

[0021] 1) Pre-preparation: Use a cutting machine to cut the purchased metal nickel plate anode material into a cuboid plate with a length of 0.3m, a width of 0.04m, and a thickness of 1cm, and then arrange the cut nickel anode materials neatly, and use titanium oxide type Welding with welding rods, and then placing the welded nickel anode material in a dilute sulfuric acid solution with a concentration of 4% for acid activation to remove rust and oil stains on the surface of the nickel metal, which is conducive to improving the uniformity of the product during the electrodeposition process. After the acid treatment, the nickel anode material is washed with water to remove acid, and then dried by air to obtain the activated nickel anode material; the large nickel metal plate purchased is cut, and then welded for electrodeposition, which is conduc...

Embodiment 2

[0025] Using the preparation method in Example 1, the electrolytic solution of the electrodeposition method in this example includes the following mass volume concentration components: nickel sulfate 80g / L, nickel chloride 45g / L, boric acid 30g / L, surfactant 2.3g / L; The process parameters of electrodeposition are: electrolyte temperature 75°C, current density 78.2A / dm 2 , pH2.3, the rotation speed of the cathode roller is 1.33m / min.

[0026] Wherein, the surfactant is sodium lauryl sulfate, and the purity (wt%) of the prepared roughened nickel foil is 99.96%.

Embodiment 3

[0028] Using the preparation method in Example 1, the electrolytic solution of the electrodeposition method in this example includes the following mass volume concentration components: nickel sulfate 61.5g / L, nickel chloride 32.3g / L, boric acid 22.7g / L, surface active Agent 1.2g / L; the process parameters of electrodeposition are: electrolyte temperature 52.5 ℃, current density 61.2A / dm 2 , pH2.9, the rotation speed of the cathode roller is 1.21m / min. Wherein, surfactant is sodium lauryl sulfate, and the purity (wt%) of the prepared roughened nickel foil is 99.94%

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com