Shot-blast cleaning device for outer wall of wind power tower drum

A shot blasting cleaning and wind power tower technology, which is applied to used abrasive treatment devices, abrasives, metal processing equipment, etc., can solve the problem of corrosion of the outer wall of wind power towers, stress concentration, low cleaning efficiency of attachments such as welding slag, etc. problems, to achieve uniform surface roughness and finish, prevent pollution, and achieve the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and examples, wherein the schematic embodiments and descriptions are only used to explain the present invention, but not to limit the present invention.

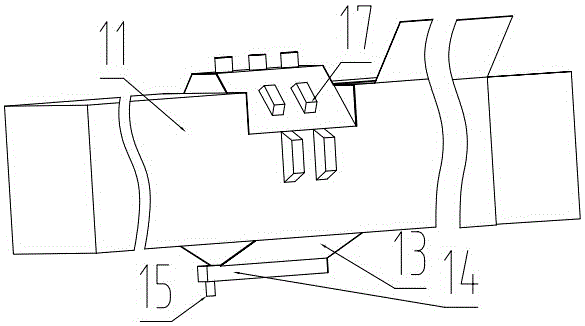

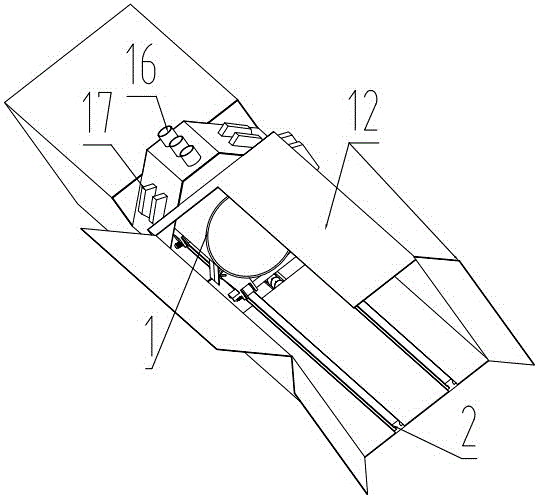

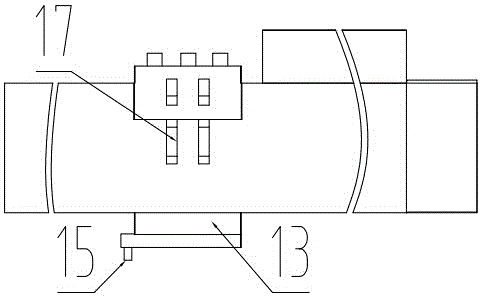

[0022] Such as Figure 1 to Figure 8 As shown, the shot blasting cleaning device for the outer wall of the wind power tower mainly includes a shot blasting device 17, a shot blasting room 11, a shot pool 13, a screw conveying device 14, a carrying vehicle 4 and a connection port; the lower side of the middle part of the shot blasting room 11 is designed There is a pill pool 13, the lower side of the pill pool 13 is designed with a screw conveying device 14, the bottom of the shot blasting room 11 is designed with a carrier car 4 and a steel rail 2, and the shot blasting room 11 and the screw conveying device 14 are designed with a connection port (dust removal and ventilation connection port) 16 and shot separation conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com