Method for preparing aromatic acid ester and aliphatic ester through directional catalytic oxidation of lignin

An oxide and catalyst technology, which is applied in the field of heterogeneous directional catalytic oxidation of lignin, can solve the problems such as the preparation of aromatic esters by heterogeneous catalytic oxidation of lignin, etc., and achieves the effect of low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

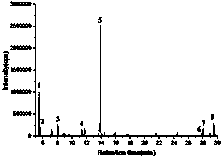

Image

Examples

Embodiment 1

[0015] Preparation of cerium oxide nanorods: 3.47 g of cerium nitrate hexahydrate was dissolved in 20 mL of deionized water, added to a 200 mL polytetrafluoroethylene liner, equipped with magnets, placed on a magnetic stirrer, and started to stir. Dissolve 50.4 g of sodium hydroxide in 140 mL of deionized water (9 mol / L), then add the sodium hydroxide solution dropwise to the cerium nitrate solution, after the addition of the sodium hydroxide solution is completed, continue to stir at room temperature for half an hour . After the stirring, put the polytetrafluoroethylene liner into the stainless steel reaction kettle, seal the reaction kettle, put it in an oven, and react at 100 °C for 72 h. After the reaction, cool to room temperature, the solution is centrifuged by a centrifuge to separate the solid, and the obtained solid is washed 5 times with deionized water and absolute ethanol respectively. The solid was dried in an oven overnight, and then calcined in a muffle furnace...

Embodiment 2

[0017] Preparation of cerium oxide nanospheres: Take 1.736 g of cerium nitrate hexahydrate and 0.294 g of trisodium citrate, dissolve them in 160 mL of deionized water, place them in a 200 mL polytetrafluoroethylene liner, configure magnets, and place them on a magnetic stirrer On, start stirring. Stir at room temperature for half an hour. After the stirring, put the polytetrafluoroethylene liner into a stainless steel reaction kettle, seal the reaction kettle, put it in an oven, and react at 200°C for 24 hours. After heating, cool to room temperature, the solution is centrifuged to separate the solid, and the obtained solid is washed 5 times with deionized water and absolute ethanol respectively. The solid was dried in an oven overnight, and then calcined in a muffle furnace at 500 °C for 3 h.

Embodiment 3

[0019] Preparation of cerium oxide nano-squares: 3.47 g of cerium nitrate hexahydrate was dissolved in 20 mL of deionized water, placed in a 200 mL polytetrafluoroethylene liner, equipped with magnets, placed on a magnetic stirrer, and started to stir, 33.6 g Sodium hydroxide was dissolved in 140 mL deionized water (6 mol / L), and then the sodium hydroxide solution was added dropwise to the cerium nitrate solution. After the sodium hydroxide solution was added dropwise, the stirring was continued for half an hour at room temperature, and the stirring was completed. Finally, put the polytetrafluoroethylene liner into a stainless steel reaction kettle, seal the reaction kettle, put it in an oven, and react at 100 °C for 24 h. After heating, cool to room temperature, the solution is centrifuged to separate the solid, and the obtained solid is washed 5 times with deionized water and absolute ethanol respectively. The solid was dried in an oven overnight, and then calcined in a muff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com