Hollow glass bead cladded with phenolic resin, and preparation method of hollow glass bead

A technology of hollow glass microspheres and phenolic resin, applied in chemical instruments and methods, inorganic pigment treatment, dyeing polymer organic compound treatment, etc., can solve the problems of poor compatibility between the surface and the medium, achieve good interface compatibility and easy operation Ease of operation and enhanced stress resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The coating process of phenolic resin on the surface of hollow glass microspheres is as follows:

[0021] 1. Hydroxylation treatment of hollow glass microspheres. Put 1 g of hollow glass microspheres into 20 mL of 20 wt % NaOH solution for 2 h, and control the temperature at 40 ° C;

[0022] 2. Separate the hollow glass microspheres in step 1 from the sodium hydroxide solution, and then drop them into a 100mL mixed solution containing phenol and formaldehyde, wherein the content of phenol is 0.01mol / L, and the molar ratio of phenol to formaldehyde is controlled at 1:1 , the temperature is controlled at 80°C, and the reaction is carried out for 2 hours under stirring;

[0023] 3. After the reaction, separate the hollow glass microspheres from the liquid, wash the microspheres with ethanol, and dry the microspheres at 50° C. to obtain hollow glass microspheres coated with phenolic resin.

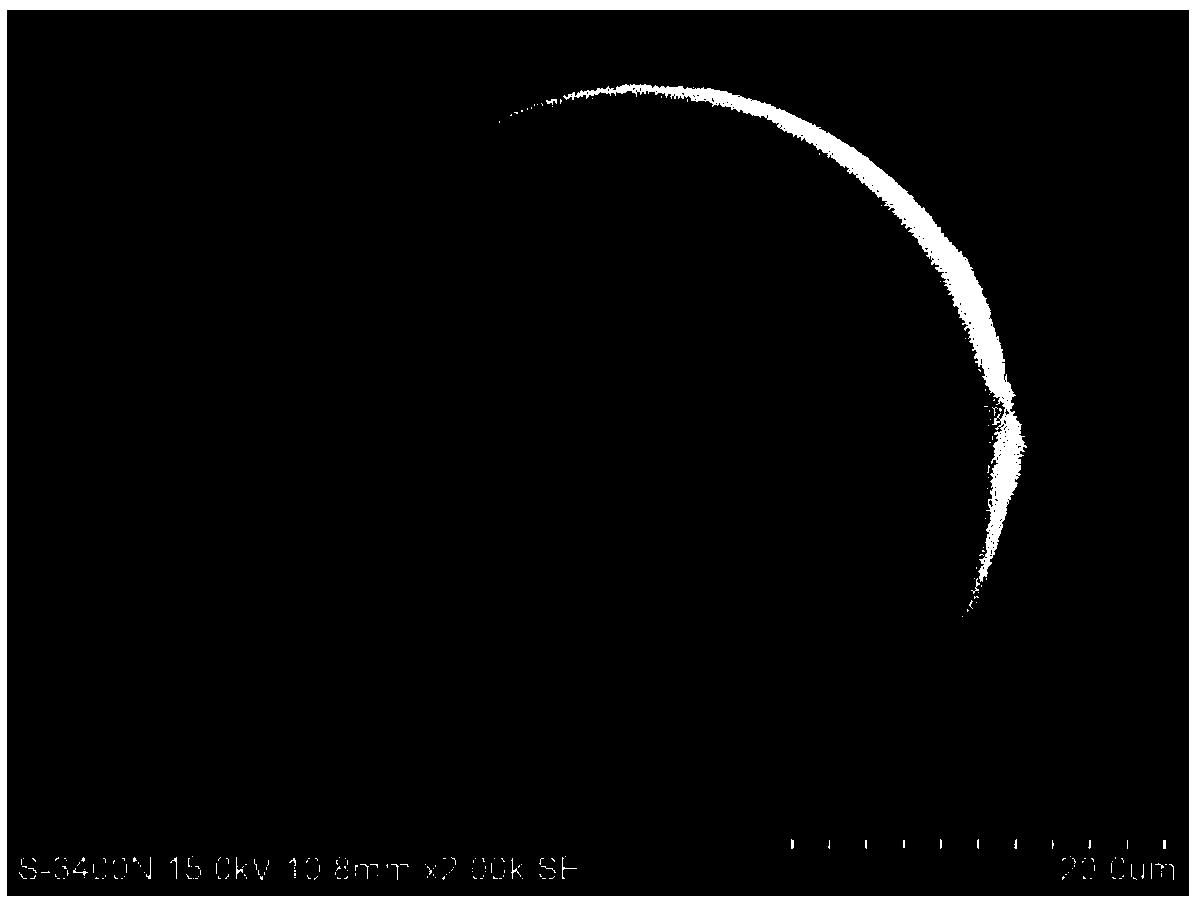

[0024] figure 1 is the SEM photograph of the obtained coated microspheres. SEM ...

Embodiment 2

[0026] The coating process of phenolic resin on the surface of hollow glass microspheres is as follows:

[0027] 1. Hydroxylation treatment of hollow glass microspheres. Treat 1 g of hollow glass microspheres in 20 mL of 30 wt % NaOH solution for 1 h, and control the temperature at 50 ° C;

[0028] 2. Separate the hollow glass microspheres in step 1 from the sodium hydroxide solution, and then put them into a 100mL mixed solution containing phenol and formaldehyde, wherein the concentration of phenol is 0.01mol / L, and the molar ratio of phenol to formaldehyde is controlled at 1:1.5 , the temperature is controlled at 70°C, and the reaction is carried out for 1 hour under stirring;

[0029] 3. After the reaction, separate the hollow glass microspheres from the liquid, wash the microspheres with ethanol, and dry the microspheres at 50° C. to obtain hollow glass microspheres coated with phenolic resin. The thickness of the resin coating at this time was about 3 μm as observed by...

Embodiment 3

[0031] The coating process of phenolic resin on the surface of hollow glass microspheres is as follows:

[0032] 1. Hydroxylation treatment of hollow glass microspheres. Treat 1 g of hollow glass microspheres in 20 mL of 25 wt % NaOH solution for 2 h, and control the temperature at 30 ° C;

[0033] 2. Separate the hollow glass microspheres in step 1 from the sodium hydroxide solution, and then drop them into a 100mL mixed solution containing phenol and formaldehyde, wherein the concentration of phenol is 0.01mol / L, and the molar ratio of phenol to formaldehyde is controlled at 1:2 , the temperature is controlled at 60°C, and the reaction is carried out for 1.5h under stirring;

[0034] 3. After the reaction, separate the hollow glass microspheres from the liquid, wash the microspheres with ethanol, and dry the microspheres at 50° C. to obtain hollow glass microspheres coated with phenolic resin. The thickness of the resin coating at this time was about 0.5 μm as observed by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com