Nano-compound deodorant and preparation method thereof

A nano-composite and deodorant technology, applied in the field of deodorants, can solve the problems of high manpower and material costs, low removal efficiency, long processing time, etc., and achieve the effect of simple operation, high removal rate and long action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

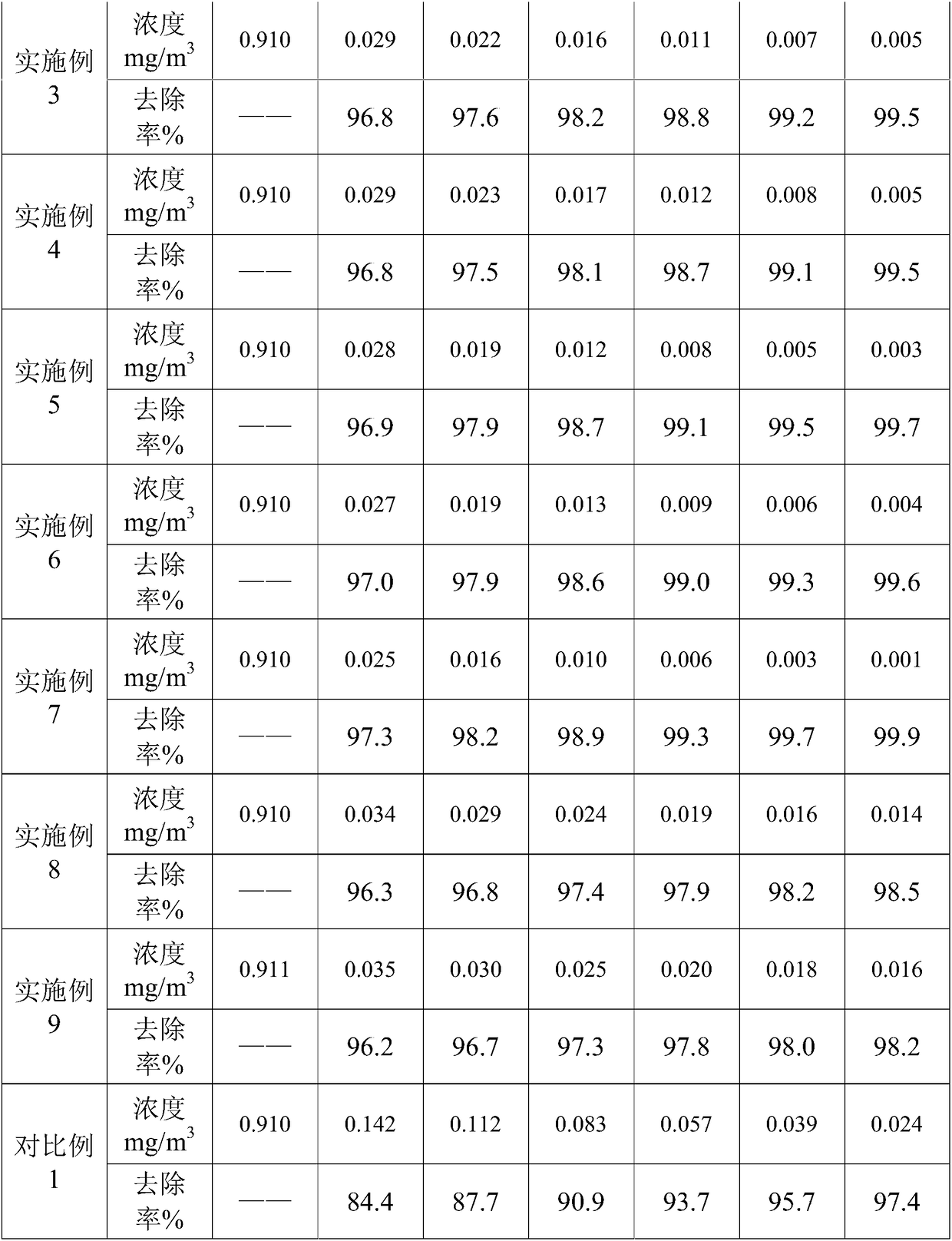

Examples

Embodiment 1

[0022] A nanocomposite deodorant comprising the following raw materials in parts by weight: 15 parts of ferric hydroxide, 5 parts of nano calcium peroxide, 0.5 part of surfactant, 1 part of basalt powder, 3 parts of alum and 1 part of dispersant; The dispersant is prepared by compounding sodium carboxymethylcellulose, sodium silicate and sodium polyacrylate, and its mass ratio is 1:2:0.3; the surfactant is composed of dodecylbenzenesulfonate with a mass ratio of 10:1 sodium dodecyltrimethylammonium bromide and sodium dodecyltrimethylammonium bromide; the nanometer calcium peroxide is a powder with a particle size of 25-200nm.

[0023] The preparation method of above-mentioned nanocomposite deodorant comprises the following steps:

[0024] S1. According to the above ratio, mix nano-calcium peroxide, ferric hydroxide and dispersant, and add 10 parts by weight of water to mix, first stir at 1400rpm for 7min, then add basalt powder, stir at 800rpm for 10min, and finally add alum, ...

Embodiment 2

[0026] A nanocomposite deodorant, comprising the following raw materials in parts by weight: 45 parts of ferric hydroxide, 25 parts of nanometer calcium peroxide, 5 parts of surfactant, 6 parts of occult powder, 7 parts of alum and 5 parts of dispersant; The dispersant is prepared by compounding sodium carboxymethylcellulose, sodium silicate and sodium polyacrylate, and its mass ratio is 1:4:0.8; the surfactant is composed of dodecylbenzenesulfonate with a mass ratio of 10:3 sodium dodecyltrimethylammonium bromide and sodium dodecyltrimethylammonium bromide; the nanometer calcium peroxide is a powder with a particle size of 25-200nm.

[0027] The preparation method of above-mentioned nanocomposite deodorant comprises the following steps:

[0028] S1. According to the above ratio, mix nano-calcium peroxide, ferric hydroxide and dispersant, and add 70 parts by weight of water to mix, first stir at 1600rpm for 4min, then add basalt powder, stir at 1200rpm for 5min, and finally ad...

Embodiment 3

[0030] A nanocomposite deodorant, comprising the following raw materials in parts by weight: 15 parts of ferric hydroxide, 5 parts of nanometer calcium peroxide, 0.5 part of surfactant, 1 part of basalt powder, 3 parts of alum, 1 part of dispersant and lemon essence 0.5 part; the dispersant is prepared by compounding sodium carboxymethylcellulose, sodium silicate, and sodium polyacrylate, and its mass ratio is 1:2:0.3; Dialkylbenzene sulfonate sodium and dodecyltrimethylammonium bromide are compounded; the nanometer calcium peroxide is a powder with a particle diameter of 25-200nm.

[0031] The preparation method of above-mentioned nanocomposite deodorant comprises the following steps:

[0032] S1. According to the above ratio, mix nano-calcium peroxide, ferric hydroxide and dispersant, and add 10 parts by weight of water to mix, first stir at 1400rpm for 7min, then add basalt powder, stir at 800rpm for 10min, and finally add alum, Ultrasonic oscillation at 600W for 8 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com