Layered nanosheet ferrierite molecular sieve as well as preparation method and application thereof

A technology of ferrierite and nano-flakes, which is applied in the direction of molecular sieves and alkali exchange compounds, molecular sieve catalysts, nanotechnology, etc., can solve the problems of high price, large sample grain size, and no record of molecular sieve application fields, etc., and achieve high selectivity, Mild crystallization conditions and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention also provides a method for preparing the layered nano-sheet ferrierite molecular sieve, which is characterized in that the method comprises the following steps:

[0028] (1) Aluminum source, water source and alkali source are stirred until completely dissolved to obtain mixture A;

[0029] (2) Add the silicon source to the solution A in batches, and stir thoroughly to obtain the mixture B;

[0030] (3) adding the first template agent R1 and the second template agent R2 into the solution B, and mixing uniformly to obtain a gel;

[0031] (4) The obtained gel is subjected to segmental dynamic crystallization in a closed container, and after the crystallization is completed, the layered nano-sheet ferrierite molecular sieve is obtained through suction filtration, drying and roasting.

[0032] In one embodiment of the present invention, in step (3), the first template R1 is pyridine, pyrrole, furan, piperidine, pyrrolidine, tetrahydrofuran or cyclohexy...

Embodiment 1

[0055] Prepare layered ferrierite with the following molar composition in the gel: SiO 2 :Al 2 o 3 :R1:R2:Na 2 O:H 2 O is 30:1:9.1:0.3:6.1:1210; R1 is pyrrole, and R2 is tetraethylammonium hydroxide.

[0056] The sodium metaaluminate of 5.4g and the sodium hydroxide of 16g are dissolved in the deionized water of 540g, make it dissolve completely through continuous stirring, mark as solution A; The silica sol (25% silicon dioxide) of 240g is added gradually to In solution A, stir well and mark it as solution B; add 20g of pyrrole and 5.8g of tetraethylammonium hydroxide (25% aqueous solution) into solution B, make it fully mixed, and mix for 60 minutes to obtain the desired gel. The resulting gel was aged at 70°C for 12h, and then crystallized at 170°C for 3 days. After the crystallization is completed, it is filtered by suction, dried at 120°C for 4 hours, and calcined at 550°C for 4 hours to obtain a layered nano-sheet ferrierite molecular sieve.

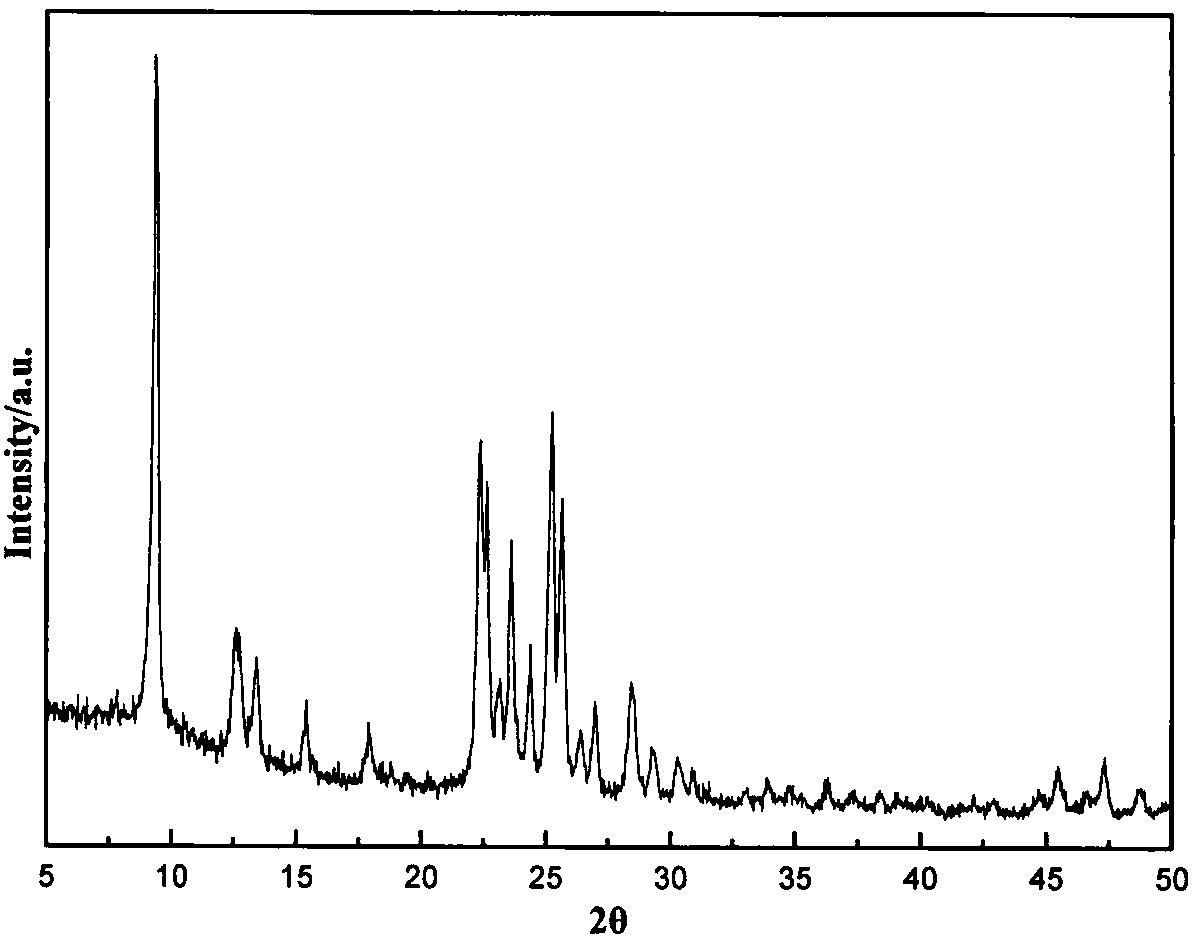

[0057] figure 1 B...

Embodiment 2

[0059] To prepare layered ferrierite, the molar composition of the gel is as follows: The molar composition in the gel is as follows: SiO 2 :Al 2 o 3 :R1:R2:Na 2 O:H 2 O is 33:1:13.3:0.33:8.3:1660; R1 is pyrrolidine, and R2 is tetraethylammonium hydroxide.

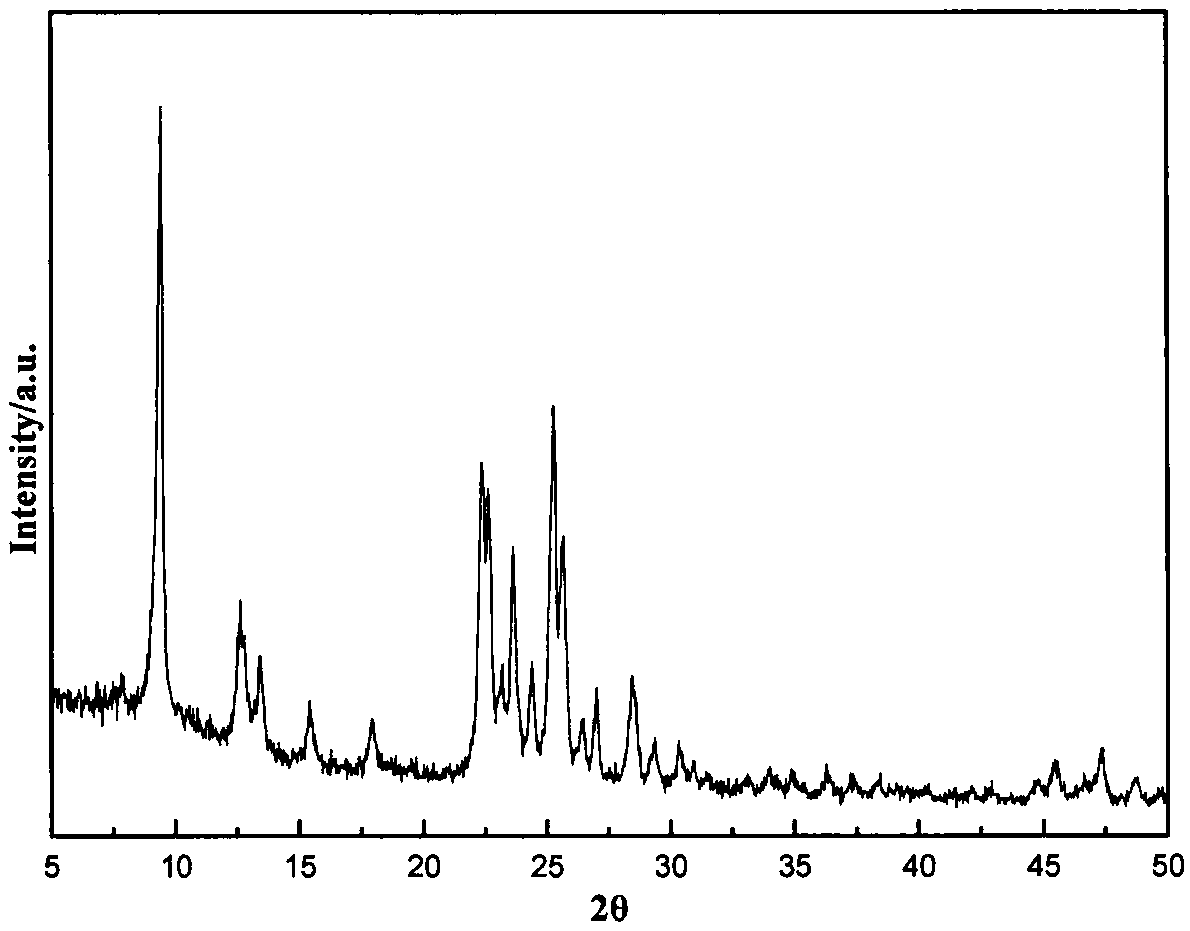

[0060] Dissolve 4.9g of sodium metaaluminate and 20g of sodium hydroxide in 720g of deionized water, and dissolve it completely with continuous stirring, marking it as solution A; gradually add 240g of silica sol (25% silicon dioxide) to the solution In A, stir well, marked as solution B; 28.4g of pyrrolidine and 5.8g of tetraethylammonium hydroxide (25% aqueous solution) are added in solution B, make it fully mix uniformly, mix 45 minutes, obtain the obtained Gel required. The obtained gel was aged at 70°C for 12h, and then crystallized at 170°C for 3 days. After the crystallization is completed, it is filtered by suction, dried at 120°C for 4 hours, and calcined at 550°C for 4 hours to obtain a layered nano-sheet f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com