Ethynylphenyl-terminated silicon-containing aryl propargyl ether resin and its synthesis, ternary resin and its preparation, composite material and its preparation

A technology of ethynyl phenyl, propargyl ether, which is applied in the fields of polymer chemistry, polymer physics and polymer material modification, and can solve the problems of poor thermal stability and low mechanical properties of composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0085] In Example 3 and Example 4, the cyanate raw material was purchased from Yangzhou Tianqi New Materials Co., Ltd., bisphenol A cyanate monomer was selected, the product model was CE01MO, and bisphenol E cyanate monomer was selected. The product model is CE09MO.

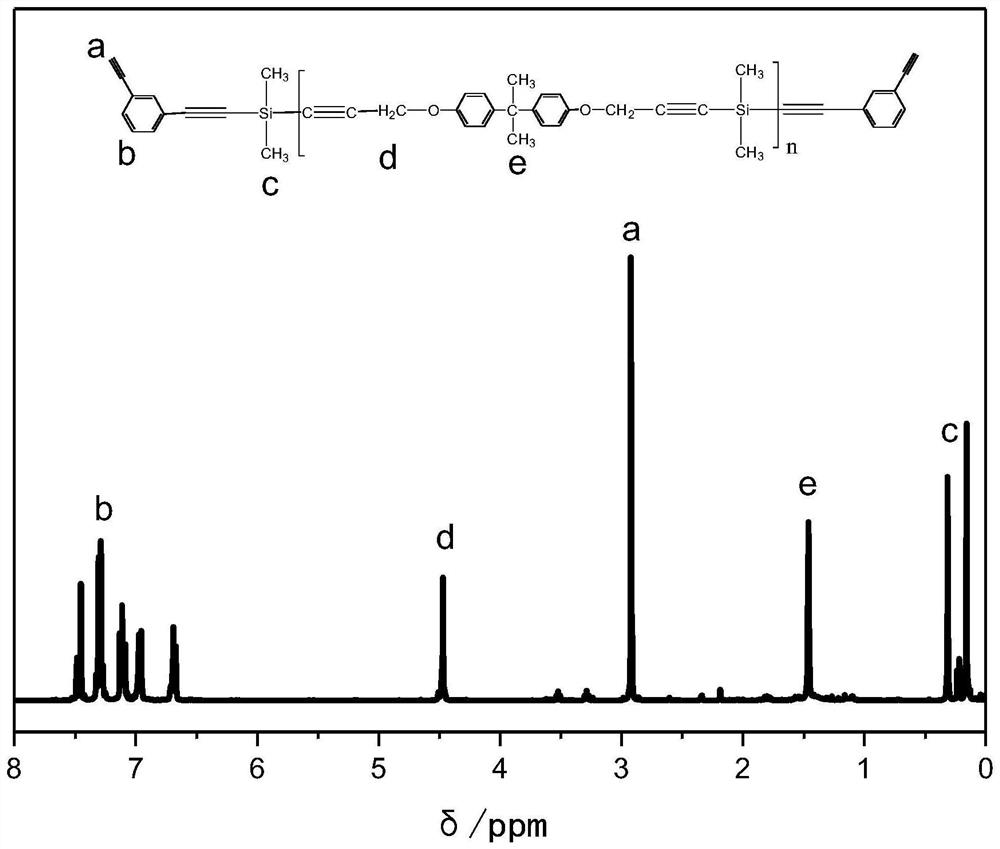

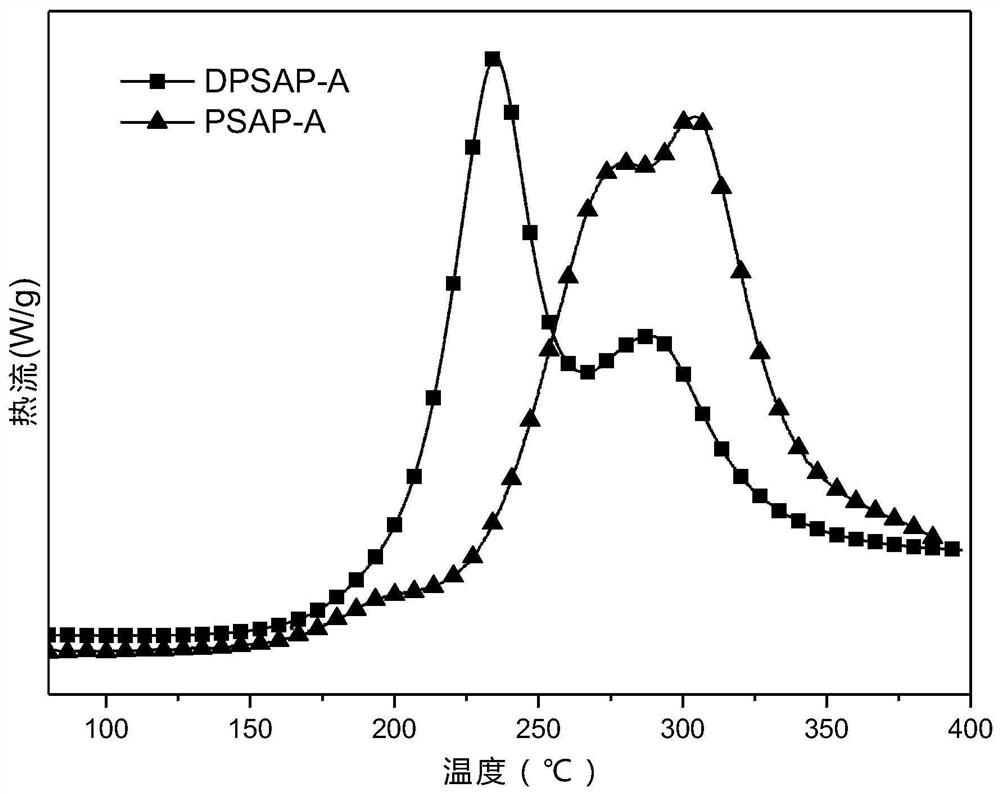

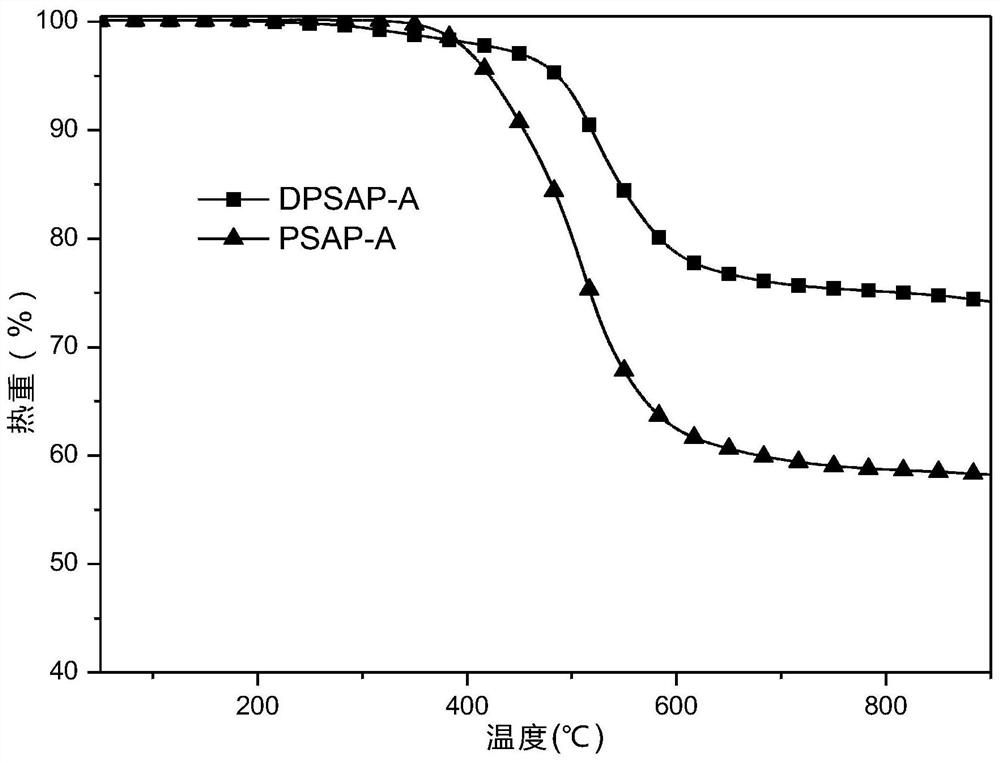

[0086] In the data testing part, the structure of the resin is tested by a hydrogen nuclear magnetic resonance instrument. The curing reaction temperature of resin can be tested by differential scanning calorimeter (DSC), and the initial temperature of curing reaction (T i ), and curing reaction peak temperature (T p ), curing reaction end temperature (T f ) and the exothermic enthalpy of the curing reaction (ΔH). The curing process of the resin can be determined by referring to the results of the resin DSC test. The thermal stability of the thermally cured resin can be tested in a nitrogen atmosphere with a thermogravimetric analyzer (TGA), and the 5% thermal weight loss temperature (T d5 ) and 800℃ residua...

Embodiment 1

[0092] Synthesis of ethynylphenyl-terminated silicon-containing bisphenol A propargyl ether resin:

[0093] The first step: the 500mL four-neck flask 1 equipped with mechanical stirring, reflux condenser, thermometer, constant pressure funnel and nitrogen inlet and outlet is vacuum pumped and roasted three times, feeds nitrogen, and takes by weighing 6.6g (0.275mol) of magnesium powder and 50mL Add THF into a four-necked flask, slowly add a solution of 28.6g (0.263mol) bromoethane and 50mL THF dropwise, control the temperature below 25°C, heat to 45°C after dropping, and keep warm for 2h to obtain ethyl bromide Magnesium Grignard reagent, cooled to room temperature with an ice-water bath; weigh 38.0g (0.125mol) of bisphenol A dipropargyl ether and dissolve it in 50mL of THF, slowly drop the solution into the reaction flask, control the temperature below 25°C, After dropping, heat to 65°C, reflux for 2h, and cool to room temperature; weigh 32.27g (0.25mol) of dimethyldichlorosi...

Embodiment 2

[0108] Preparation of ethynylphenyl-terminated silicon-containing bisphenol A propargyl ether resin by butyllithium method:

[0109] Step 1: Vacuum bake a 500mL four-neck flask equipped with mechanical stirring, reflux condenser, thermometer, constant pressure funnel and nitrogen gas inlet and outlet three times, and then blow nitrogen gas into it. Weigh 30.42g of bisphenol A dipropargyl ether and 100mL of THF into the four-neck flask I, stir evenly; use a liquid nitrogen / ethanol bath to cool down to -10°C, extract 80mL of 2.5M n-butyllithium solution, and pass Slowly add dropwise through a constant pressure dropping funnel; after the dropwise addition, warm up to room temperature and react for 2 hours; cool down to -10°C with a liquid nitrogen / ethanol bath; weigh 25.8g of dimethyldichlorosilane and dissolve it in 100mLTHF, The dropping funnel was slowly added dropwise to the reaction flask I; the temperature was raised to room temperature for 0.5h; the intermediate product wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com