Carbon fiber reinforced PMI (Polymethacrylimide) foam-pyramid sandwich plate composite structure and preparation method thereof

A composite structure and pyramid technology, applied in the direction of metal layered products, chemical instruments and methods, layered products, etc., can solve problems such as softening and failure, and achieve the effects of improved mechanical properties, excellent comprehensive properties, and low manufacturing process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

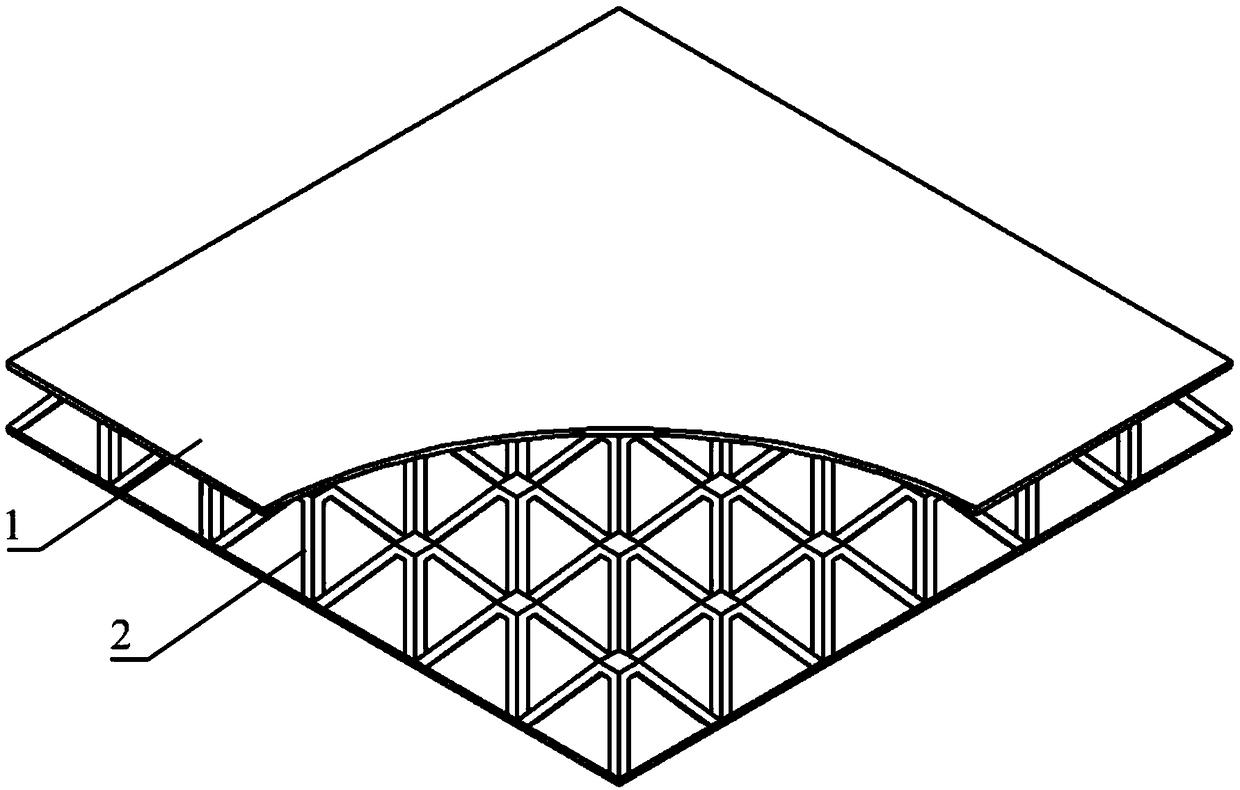

preparation example Construction

[0032]The present invention is a carbon fiber reinforced PMI foam-pyramid sandwich panel composite structure and a preparation method thereof. First, a pyramid lattice core is prepared; the pyramid lattice core and the panel are welded to form a pyramid lattice sandwich panel; carbon fiber or recycled carbon fiber is used as a Reinforcing material, using methacrylonitrile and methacrylic acid as comonomers, adding initiator, crosslinking agent, foaming agent, nucleating agent, etc. to prepare foamable polymer; filling foamable polymer into pyramid The pores of the lattice sandwich panel are freely foamed and heat treated in an oven to prepare carbon fiber reinforced PMI foam that completely fills the pores of the pyramid lattice sandwich panel, and then naturally cooled to room temperature to obtain carbon fiber reinforced PMI foam-pyramid lattice sandwich panel. Composite structure. Specific steps are as follows:

[0033] S1. Use the punched diamond mesh or the flattened str...

Embodiment 1

[0047] (1) The punched 316 stainless steel diamond mesh is formed by molding technology to form the pyramid lattice core 2, and then the 316 stainless steel panel 1 and the pyramid lattice core 2 are cleaned with metal cleaning agent to remove oil stains and rust, and brazing is used to remove oil stains and rust. The panel 1 is connected with the pyramid lattice core 2 to form a pyramid lattice sandwich panel;

[0048] (2) Heat the carbon fiber strands in an air atmosphere at 400°C for 20 minutes, then immerse them in nitric acid with a mass concentration of 20% and boil for 10 minutes, then rinse them with deionized water until neutral, and finally cut them into 2mm short cuts carbon fiber.

[0049] (3) Mix 40 methacrylonitrile, 40 methacrylic acid, 0.1 azobisisobutyronitrile, 0.5 acrylamide, 2.0 propylene glycol, and 0.5 urea according to the ratio by weight, and pass 1000 r at a water bath temperature of 15 °C. / min mixer speed mixing for 1h to stir the reaction solution ...

Embodiment 2

[0055] (1) The flattened TC4 titanium alloy mesh is formed by folding technology to form the pyramid lattice core 2, and then the TC4 titanium alloy panel 1 and the pyramid lattice core 2 are cleaned with metal cleaning agent to remove oil stains and rust, and laser Weld the panel 1 and the pyramid lattice core 2 to form a pyramid lattice sandwich panel;

[0056] (2) Rinse the regenerated carbon fiber precursor with deionized water to neutrality, and finally cut it into 3mm chopped carbon fibers.

[0057] (3) Mix 50 methacrylonitrile, 50 methacrylic acid, 0.2 azobisisobutyronitrile, 0.6 methacrylamide, 2.0 formamide, and 1.0 methylurea according to the ratio by weight, and put them in a water bath at 20°C. Under the temperature, the reaction solution was stirred evenly by mixing at 2000r / min mixer speed for 2h;

[0058] (4) adding carbon fibers with a ratio of 10 parts by weight to the reaction solution, placing the mixed solution in an ultrasonic disperser at a frequency of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com