Graphene-reinforced PMI foam-pyramid sandwich panel composite structure and preparation method thereof

A technology of composite structures and pyramids, applied in the direction of metal layered products, chemical instruments and methods, layered products, etc., can solve the problems of foam strength and stiffness reduction, etc., and achieve the improvement of mechanical properties, increase of tensile strength, and high specific strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

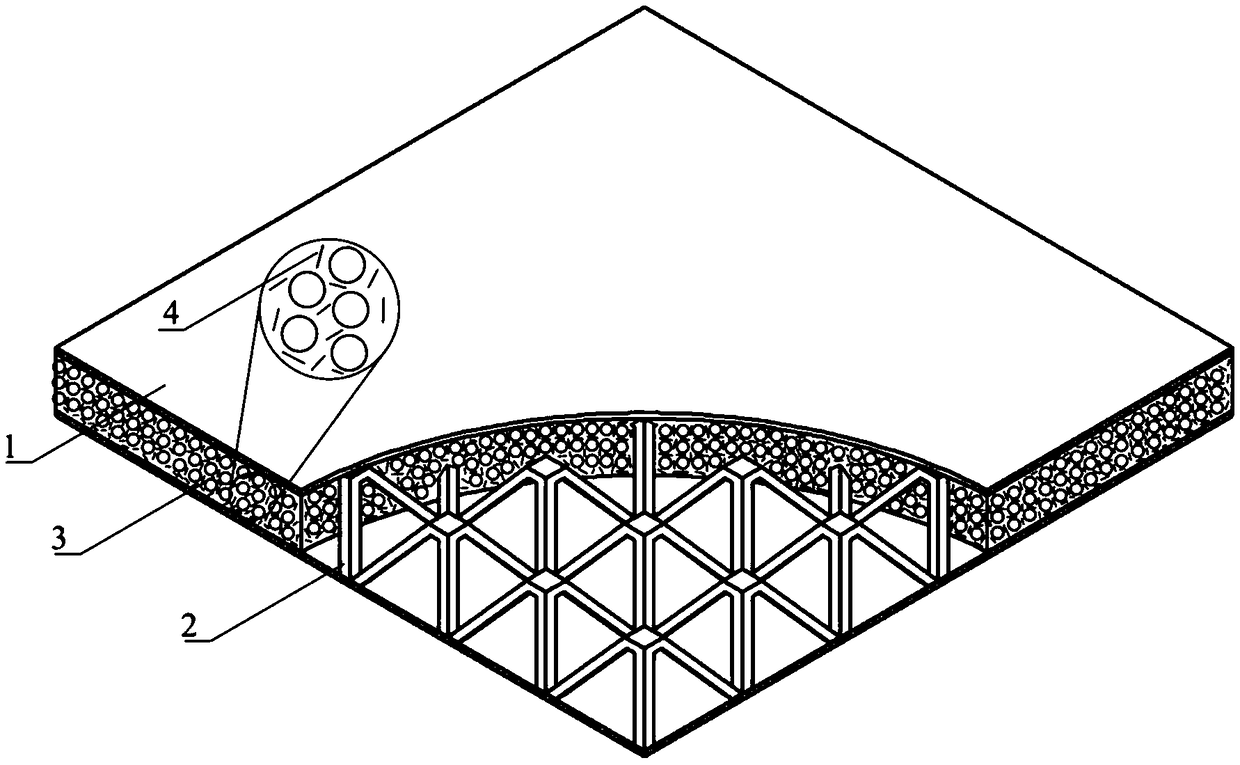

[0032] A kind of graphene reinforced PMI foam-pyramid sandwich plate composite structure of the present invention and preparation method thereof, first prepare pyramid lattice core 2, pyramid lattice core 2 and panel 1 are welded into pyramid lattice sandwich plate; Utilize graphite Alkene is used as a reinforcing material, and methacrylonitrile and methacrylic acid are used as comonomers, and initiators, crosslinking agents, foaming agents, and nucleating agents are added to prepare foamable polymers; the foamable polymers are filled into The pores of the pyramid lattice sandwich plate are freely foamed and heat-treated in an oven to prepare graphene-enhanced PMI foam that is completely filled in the pores of the pyramid lattice sandwich plate, and then naturally cooled to room temperature to obtain graphene-enhanced PMI foam-pyramid lattice Sandwich panel composite structure. Specific steps are as follows:

[0033] S1. Form the pyramidal lattice core 2 by molding or folding...

Embodiment 1

[0046] (1) The punched 316 stainless steel rhombic mesh is formed into a pyramid lattice core 2 by molding technology, and then the 316 stainless steel panel 1 and the pyramid lattice core 2 are cleaned with a metal cleaning agent to remove oil and rust. The panel 1 is connected with the pyramid lattice core body 2 to form a pyramid lattice sandwich panel;

[0047] (2) Mix 40 methacrylonitrile, 40 methacrylic acid, 0.1 azobisisobutyronitrile, 0.5 acrylamide, 2.0 propylene glycol, and 0.5 urea according to the ratio of parts by weight. / min mixer speed and mix for 1h to stir the reaction solution evenly;

[0048] (3) Graphene with a weight and number ratio of 2 is added in the reaction solution, the mixed solution is placed in an ultrasonic disperser at a frequency of 5 kHz, ultrasonically dispersed for 20 min, and now the graphene can be uniformly dispersed in the reaction solution;

[0049] (4) Pour the reaction solution into a glass mold, then put it into a water bath, and ...

Embodiment 2

[0053] (1) The flattened TC4 titanium alloy expanded mesh is folded to form a pyramid lattice core 2, and then the TC4 titanium alloy panel 1 and the pyramid lattice core 2 are cleaned with a metal cleaning agent to remove oil and rust. Welding connects the panel 1 and the pyramid lattice core body 2 to make a pyramid lattice sandwich panel;

[0054] (2) Mix 50 methacrylonitrile, 50 methacrylic acid, 0.2 azobisisobutyronitrile, 0.6 methacrylamide, 2.0 formamide and 1.0 methyl urea according to the ratio of parts by weight. Under the temperature, the reaction solution is stirred evenly by mixing at a speed of 2000r / min for 2 hours;

[0055] (3) the graphene that is 10 is added in the reaction solution by weight part ratio, the mixed solution is placed in the ultrasonic disperser under 30kHz frequency, ultrasonic dispersion 30min, now graphene can be evenly dispersed in the reaction solution;

[0056] (4) Pour the reaction solution into a glass mold, then put it into a water ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com