A method for gas upgrading in scrap steel preheating system

A technology for coal gas and scrap steel, applied in the field of metallurgy, can solve the problems of increasing enterprise equipment investment, long-term maintenance costs, inability to be widely used in terms of practicability and economy, and increasing the burden on the gas dust removal system, so as to shorten the smelting cycle and improve the enterprise Economic benefits, the effect of shortening the steelmaking cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

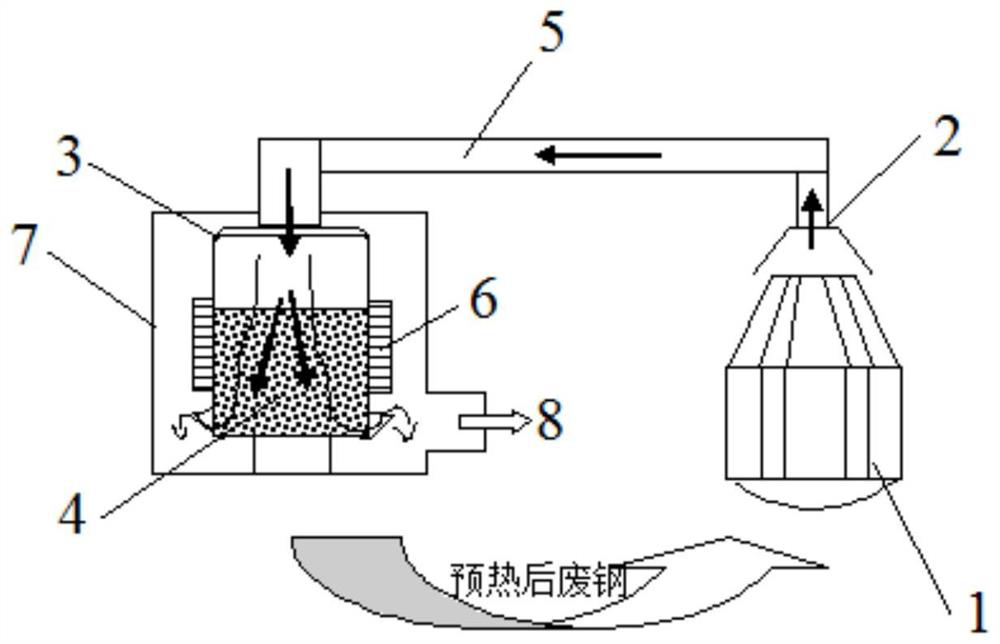

[0040] A method for gas upgrading in a converter scrap steel preheating system, such asfigure 1 As shown, the high-temperature gas generated by the converter 1 during the steelmaking process is recovered through the converter flue gas hood 2 , and the high-temperature gas is used to preheat scrap steel and charge 4 in the scrap heating furnace 3 . The 1500-1700°C high-temperature gas produced in the converter 1 steelmaking process contains 58% CO, 28% CO 2 , and 2% O 2 , and the rest are N 2 、H 2 , the amount of coke is added according to 0.1% of the mass of scrap steel, and the amount of limestone is added according to 5% of the total mass of steelmaking. Coke and limestone are evenly mixed in scrap steel, and added to scrap steel heating furnace 3 for preheating. When the recovered high-temperature gas When the temperature is very high, that is, around 708°C, CO can occur 2 (g)+C(s)=2CO(g), CO in gas 2 Converted to CO, when the limestone starts to decompose at 838°C afte...

Embodiment 2

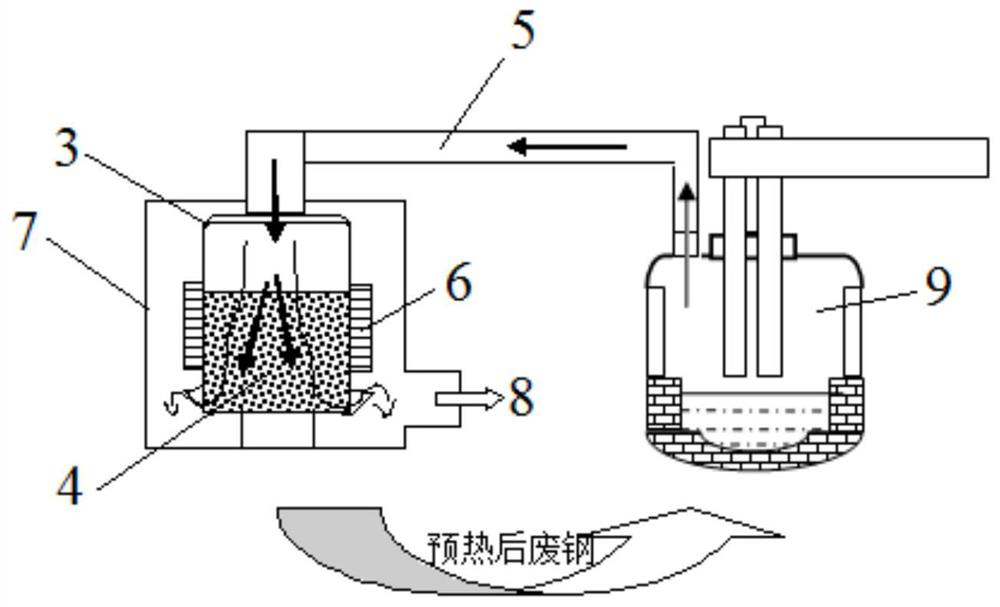

[0044] On the basis of Example 1, this embodiment adopts the high-temperature coal gas produced by electric furnace 9 to preheat scrap steel, as figure 2 As shown, the 1500-1700°C high-temperature gas produced during the steelmaking process of the electric furnace 9 contains 31% CO, 18% CO 2 , and 13% O 2 , and the rest are N 2 、H 2 , add electrode powder according to 1% of the total mass of scrap steel, and add limestone according to 7% of the total mass of steelmaking, and finally increase the concentration of CO to 72%, and reduce the concentration of oxygen to 0.6%.

Embodiment 3

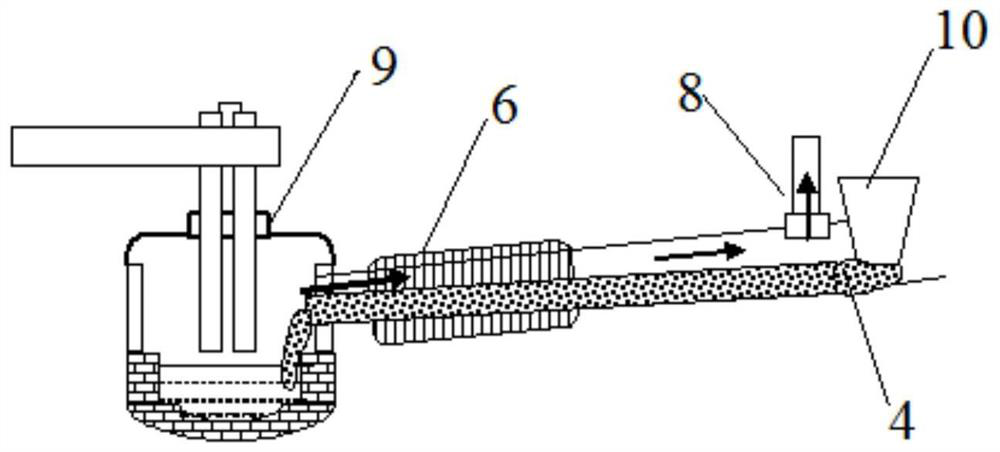

[0046] This embodiment is a gas upgrading method in the electric furnace scrap steel preheating system, which adopts continuous production, such as image 3 As shown, the high-temperature flue gas produced by the electric furnace 9 in the steelmaking process, that is, the electric furnace gas, is directly used to preheat the scrap steel and the charge 4, and an inlet for adding scrap steel is provided at the upper end of the side of the electric furnace 9, through which the electric furnace 9 itself generates The electric furnace gas preheats the steel scrap and charge 4 entering the electric furnace, and after preheating, the steel scrap and charge enter the electric furnace for smelting. Electric furnace gas generated at the beginning contained 28% CO, 22% CO 2 , and 5% O 2 , and the rest are N 2 、H 2 , coke powder is added at 1.2% of steel scrap, the particle size of coke powder is 3-40mm, dolomite is added at 3% of steelmaking quality, limestone is added at 5% of steelm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com