Preparation method of high-solid star-shaped acrylic polyurethane dispersion for varnish

A technology of acrylic polyurethane and overcoat varnish, applied in the direction of coating, can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

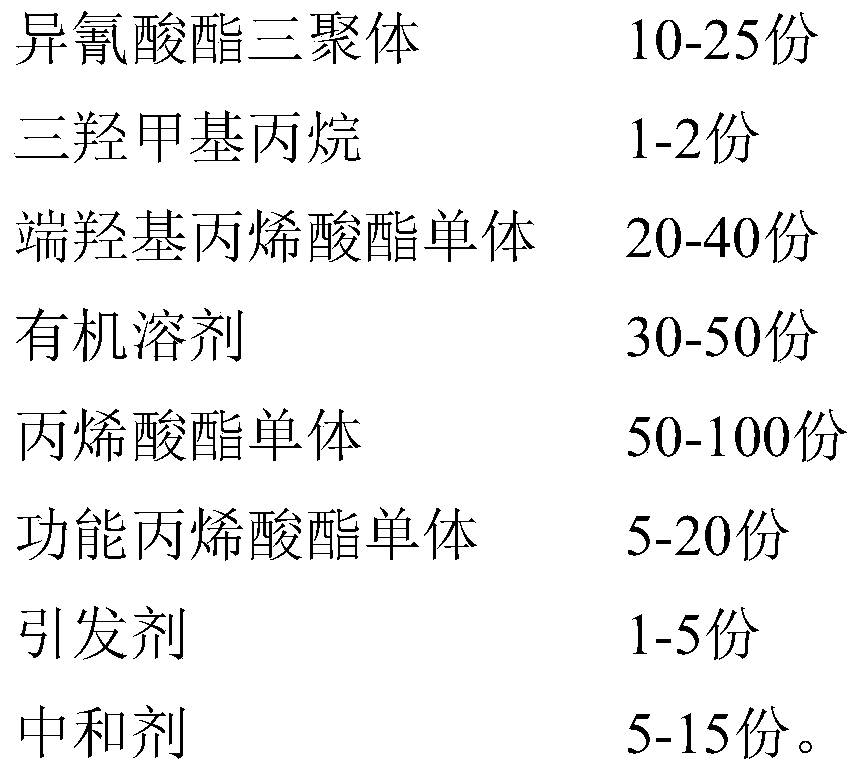

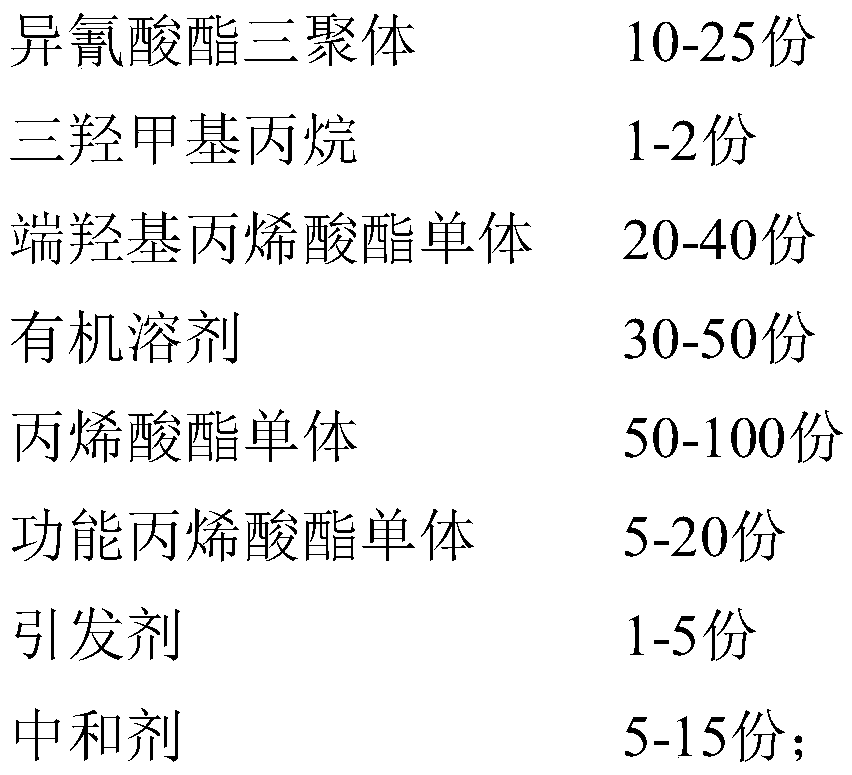

Method used

Image

Examples

Embodiment 1

[0031] (1) Heat 20g of hexamethylene isocyanate trimer and 1g of trimethylolpropane in a reactor to 50-60°C, react until the NCO content is 13.3%, and obtain 21g of A1;

[0032] (2) React 21g of A1 with 24g of hydroxyethyl acrylate at 60-80°C until the NCO content is <0.1%, to obtain 45g of A2;

[0033] (3) Add 45g of propylene glycol methyl ether to 45g of A2 to obtain 90g of A3;

[0034] (4) Heat 90g A3 to 120-140°C, then mix uniformly 10g of acrylic acid, 50g of n-butyl acrylate, 10g of isobornyl acrylate, 15g of methyl methacrylate and 3g of initiator dicumyl peroxide , added dropwise to A3 at a uniform speed within 3 hours, and kept warm for 1 hour after dropping to obtain 178g A4;

[0035] (5) Cool 178g of A4 to 100°C, then extract 33g of propylene glycol methyl ether under 0.08MPa negative pressure to obtain 145g of A5;

[0036] (6) Cool 145g of A5 to 60°C, add 12g of neutralizing agent dimethylethanolamine dropwise at a constant speed within 0.5h, keep stirring for 1...

Embodiment 2

[0039] (1) Heat 25g of hexamethylene isocyanate trimer and 1.1g of trimethylolpropane in a reactor to 50-60°C, react until the NCO content is 16.5%, and obtain 26.1g of A1;

[0040] (2) React 21g of A1 with 28g of hydroxyethyl acrylate at 60-80°C until the NCO content is <0.1%, to obtain 54.1g of A2;

[0041] (3) Add 45g of propylene glycol butyl ether to 54.1g of A2 to obtain 99.1g of A3;

[0042] (4) Heat 99.1g of A3 to 120-140°C, then mix uniformly 10g of acrylic acid, 40g of n-butyl acrylate, 10g of isobornyl acrylate, 20g of methyl methacrylate and initiator tert-butyl peroxide 2.4g, added dropwise to A3 at a constant speed within 3 hours, and kept warm for 1 hour after dropping, to obtain 181.5g A4;

[0043] (5) Cool 181.5g of A4 to 100°C, and then extract 32.5g of propylene glycol butyl ether under a negative pressure of 0.08MPa to obtain 149g of A5;

[0044] (6) Cool 149g of A5 to 60°C, add 12g of neutralizing agent dimethylethanolamine dropwise at a constant speed w...

Embodiment 3

[0047] (1) Heat 25g of hexamethylene isocyanate trimer and 1.1g of trimethylolpropane in a reactor to 50-60°C, react until the NCO content is 16.5%, and obtain 26.1g of A1;

[0048] (2) 21g of A1 was reacted with 30g of hydroxypropyl acrylate at 60-80°C until the NCO content was <0.1%, and 56.1g of A2 was obtained;

[0049] (3) Add 45 g of propylene glycol butyl ether to 56.1 g of A2 to obtain 101.1 g of A3;

[0050] (4) Heat 101.1g of A3 to 120-140°C, then mix uniformly 9g of acrylic acid, 40g of n-butyl acrylate, 9g of isobornyl acrylate, 20g of methyl methacrylate and initiator tert-butyl peroxide 2.4g, added dropwise to A3 at a constant speed within 3 hours, and kept warm for 1 hour after dropping, to obtain 181.5g A4;

[0051] (5) Cool 181.5g of A4 to 100°C, and then extract 32.5g of propylene glycol butyl ether under a negative pressure of 0.08MPa to obtain 149g of A5;

[0052] (6) Cool 149g of A5 to 60°C, add 12g of neutralizing agent dimethylethanolamine dropwise at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com