Method for separating wuyiencin from fermentation liquor

A technology of Wuyiencin and fermentation liquid, which is applied in the field of bioengineering, can solve the problems of low purity and low extraction efficiency of Wuyiencin, and achieve high-efficiency extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

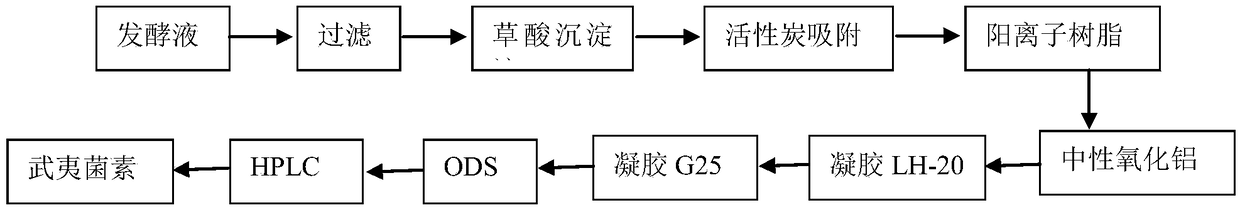

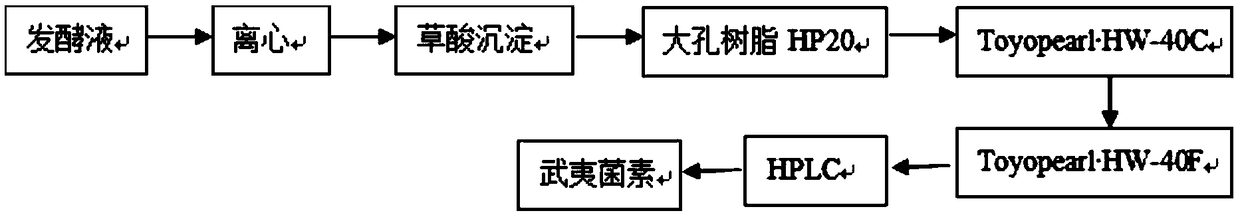

Method used

Image

Examples

Embodiment 1

[0064] 1. Fermentation and cultivation of Wuyiencin-producing strains

[0065] Use a scalpel to cut the Wuyiencin-producing strain - Streptomyces nonhygroscopicus Wuyi var. CK15 from the MS medium by 2 cm 2 Inoculate into Erlenmeyer flasks equipped with 200ml of fermentation medium, shake and culture at 28°C and 220rpm for 64h on a shaker, and ferment 30 flasks in total.

[0066] MS medium components are: mannitol 20g / L, soybean powder 20g / L, agar powder 20g / L.

[0067] The composition of the fermentation medium is: corn flour 20g / L, soybean flour 25g / L, glucose 25g / L, calcium carbonate 4g / L.

[0068] 2. Crude extraction of Wuyiencin

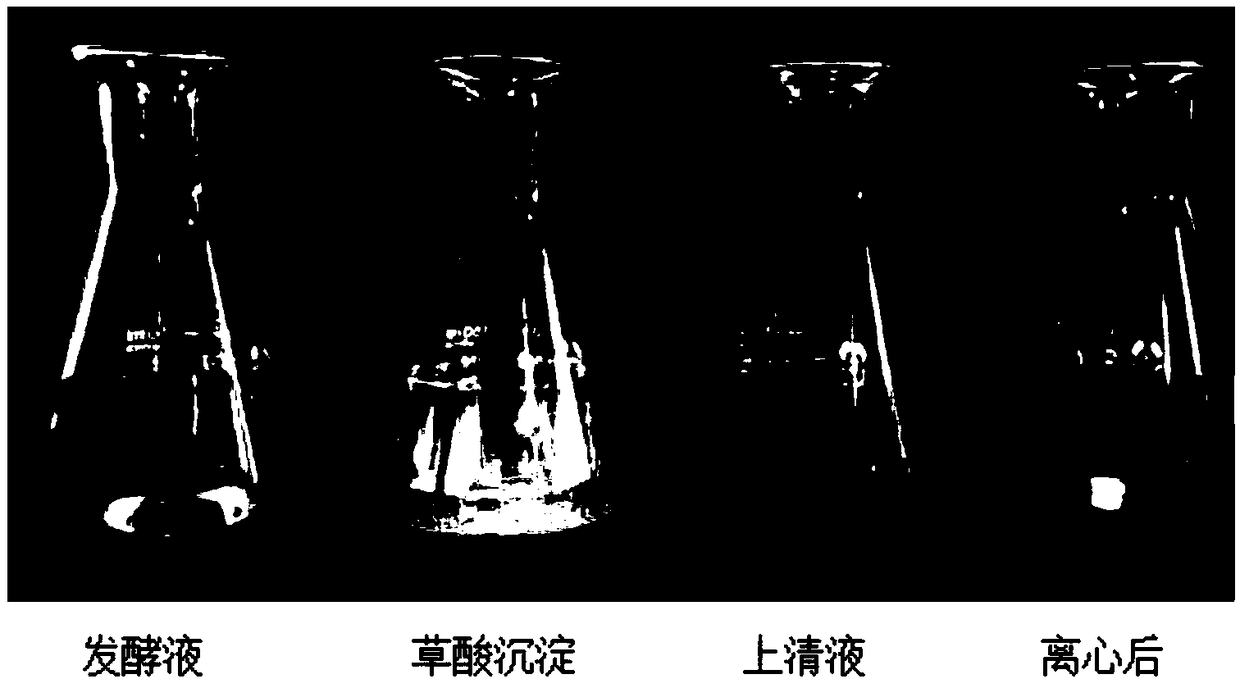

[0069] (1) Pretreatment of fermented liquid: Centrifuge 30 bottles of fermented liquid at room temperature (9500rpm, 15min), remove culture medium residue and bacterial cells therein, collect 4.8L fermented liquid altogether, determine by HPLC, titer is 1100ppm;

[0070] (2) Add oxalic acid to the fermentation broth, adjust the pH to 2.0-2.5,...

Embodiment 2

[0086] 1. Fermentation and cultivation of Wuyiencin-producing strains

[0087](1) Strain culture: inoculate CK15 onto 10 MS plates with a diameter of 9 cm, cultivate at 28°C for 7 days, and then use 50 ml of sterile water to elute the spores into a 200 ml Erlenmeyer flask;

[0088] The composition of MS medium is the same as that in Example 1.

[0089] (2) Seed liquid culture: inoculate the above spore liquid into a 50L fermenter with 30L of culture medium, at a temperature of 28°C, a speed of 200rpm, an air flow ratio of 1:0.5, and a tank pressure of 0.1kg / cm 2 Cultivate 24h under the condition of obtaining seed liquid;

[0090] The medium components are: glucose 10g / L, peptone 5g / L, yeast powder 3g / L, sucrose 260g / L.

[0091] (3) Fermentation tank culture: Transfer the vigorously growing primary seed liquid into a 500L fermenter tank with 300L fermentation medium inside, at a temperature of 28°C, a speed of 200rpm, an air flow ratio of 1:0.55, and a tank pressure of 0.12 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com