Multi-level-pore composite material supported with TS-1 zeolite film and preparation method of composite material

A composite material, TS-1 technology, applied in the direction of chemical instruments and methods, crystalline aluminosilicate zeolite, ceramic products, etc., can solve problems such as the limitation of application range, achieve easy adjustment and control, simple and easy repeatability, and reduce side effects Effects of reaction and carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment is a micron-scale through-hole α-Al 2 o 3 Preparation of monolithic material A1.

[0047] 0.09g polyethylene oxide, 4.32g AlCl 3 ·6H 2 O was dissolved in 4 mL of water and 4.35 g of absolute ethanol in a mixed solvent, and stirred until it was uniformly dissolved to form a colorless and transparent homogeneous solution. Add 3.11 g of propylene oxide under stirring and ice-bath conditions, and after vigorously stirring for 5 minutes, transfer the resulting mixture sol into a polytetrafluoroethylene test tube or a glass tube. The tube was sealed, aged at 40°C for 24 hours, and the wet gel was dried and calcined to obtain micron-sized through-hole α-Al 2 o 3 Overall material A1.

Embodiment 2

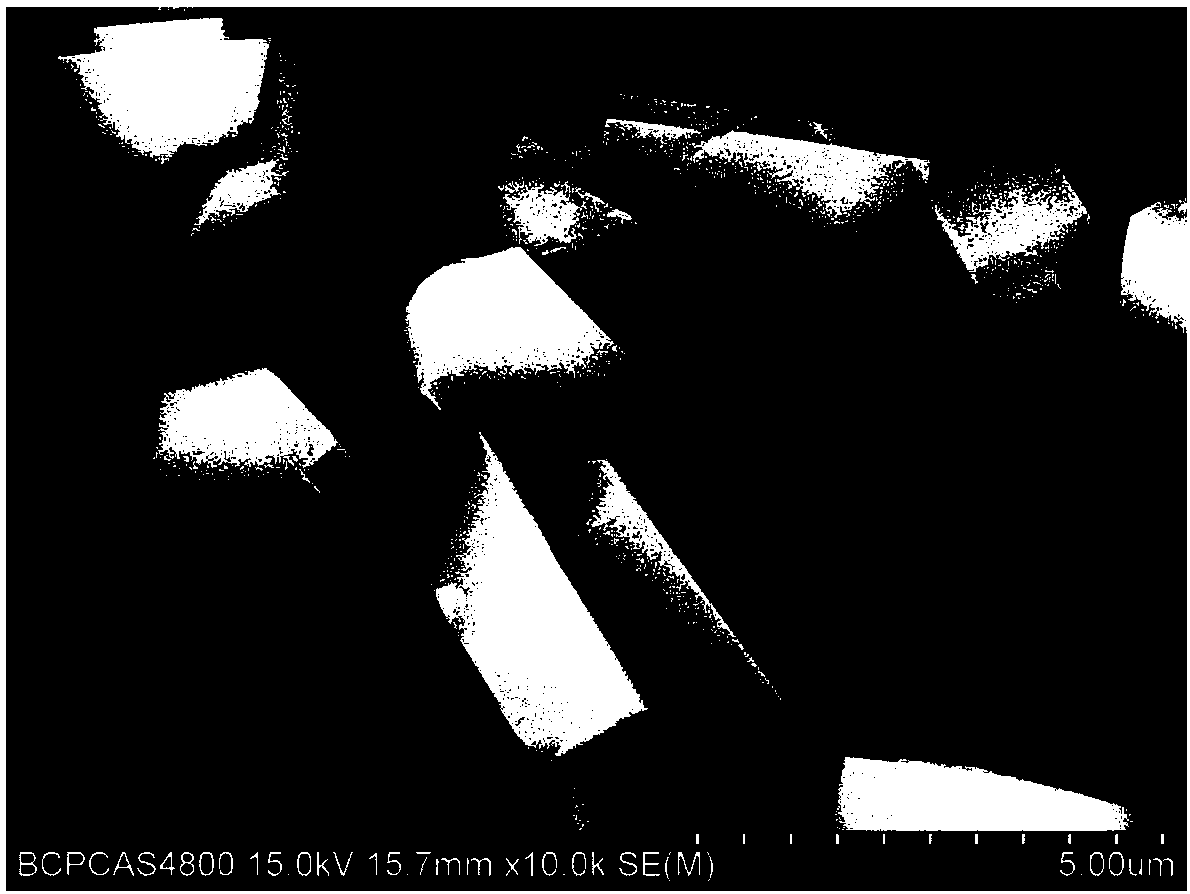

[0052] Dissolve 0.25g of potassium hydroxide in 20g of water, add 2.52g of tetrapropylammonium bromide and stir to mix evenly. Slowly add 1.67 g of tetraethyl orthosilicate into the system under vigorous stirring, and after mixing uniformly, continue hydrolysis for 16 hours under magnetic stirring. Add 0.08 g of tetrabutyl titanate and 0.2 g of hydrogen peroxide into 8 g of water, stir for 4 hours, then slowly drop them into the silicon source hydrolysis solution system, and stir for 1 hour after the dropwise addition is complete. The temperature of the system was raised to 80°C, and the alcohol was fully removed by heating for 5 hours. Water was added to replenish the lost mass, and the system was cooled to room temperature to obtain a crystallization solution. Under ultrasonic or negative pressure, the micron-scale through-hole α-Al 2 o 3 The carrier was immersed in the crystallization solution for 30min. Then, the carrier and the crystallization solution were placed in a...

Embodiment 3

[0054] Dissolve 0.18g of sodium hydroxide in 22.34g of water, add 1.95g of TPAOH and stir to mix evenly. Slowly add 1.67 g of tetraethyl orthosilicate into the system under vigorous stirring, and after mixing uniformly, continue hydrolysis for 24 hours under magnetic stirring. Add 0.07g of tetrabutyl titanate and 0.2g of hydrogen peroxide into 5g of water, stir for 2 hours, then slowly drop into the silicon source hydrolysis solution system, and stir for no less than 30 minutes after the dropwise addition. The temperature of the system was raised to 85°C, and the alcohol was fully removed by heating for 3 hours, and the lost mass was replenished by adding water, and the system was lowered to room temperature to obtain a crystallization solution. Under ultrasonic or negative pressure, the micron-scale through-hole α-Al 2 o 3 The carrier was immersed in the crystallization solution for 30min. Then the carrier and the crystallization solution were placed in a closed stainless ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| macropore | aaaaa | aaaaa |

| mesopore | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com