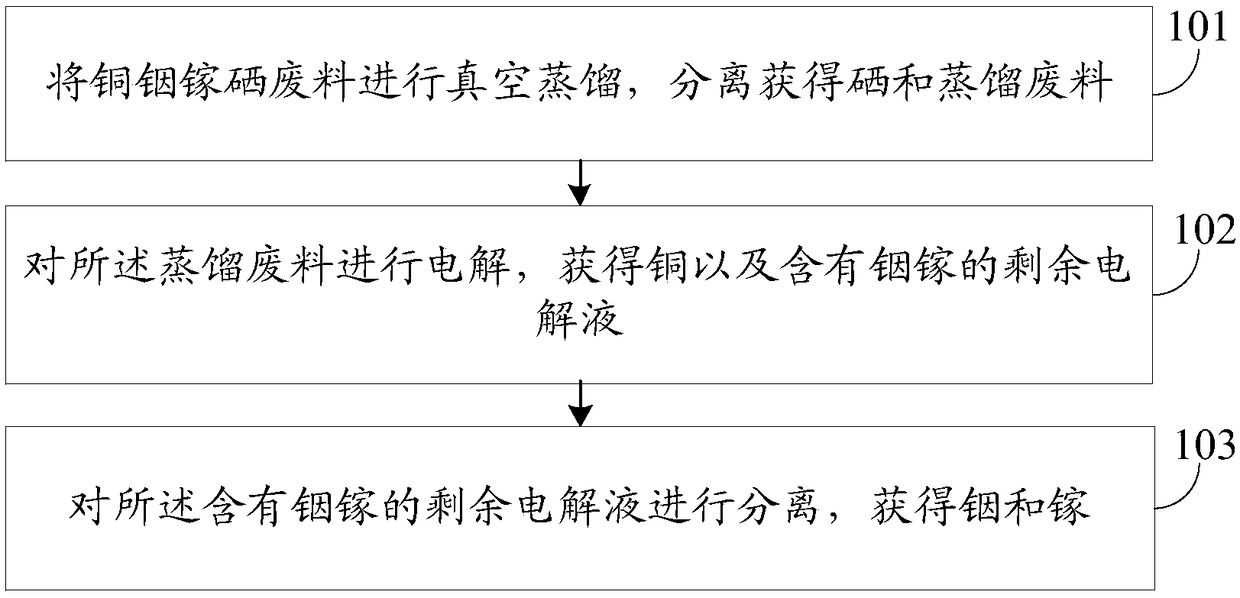

Recovery method of copper-indium-gallium-selenium waste materials

A technology of copper indium gallium selenide and recovery method, which is applied in the direction of element selenium/tellurium, improvement of process efficiency, photography process, etc., can solve the problems of large environmental pollution and waste water, and achieve the goals of reducing pollution, simple process and reducing emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Put the copper indium gallium selenium waste into a vacuum furnace for distillation. The vacuum degree of the vacuum furnace is 5Pa, the distillation temperature is 400°C, and the distillation time is 2 hours. Selenium and distillation waste are obtained by condensing and separating in a condenser; the purity of selenium powder is > 99.9%, the recovery rate> 99%;

[0068] The above-mentioned distillation waste is used as the anode, and the stainless steel plate is used as the cathode. The distillation waste is dissolved in the copper sulfate electrolyte in the electrolytic cell for electrolysis. The voltage of the electrolytic cell is 0.3V, the electrolysis temperature is 30°C, and the current density is 200A / m 2 , copper is precipitated in the cathode, and the remaining electrolyte solution containing indium gallium is obtained; the copper purity is >99.99%;

[0069] adjusting the pH value of the remaining electrolyte solution containing indium gallium to 0.01, using P...

Embodiment 2

[0073] Put the copper indium gallium selenide waste into a vacuum furnace for distillation. The vacuum degree of the vacuum furnace is 30Pa, the distillation temperature is 600°C, and the distillation time is 3 hours. Selenium and distillation waste are obtained after separation by a condenser; the purity of selenium powder is >99.9 %, recovery > 98%;

[0074] The above-mentioned distillation waste is used as the anode, and the stainless steel plate is used as the cathode. The distillation waste is dissolved in the copper sulfate electrolyte in the electrolytic cell for electrolysis. The voltage of the electrolytic cell is 0.5V, the electrolysis temperature is 60°C, and the current density is 400A / m 2 , depositing copper in the cathode, and obtaining the remaining electrolyte containing indium gallium; wherein, the purity of copper is >99.99%;

[0075] Adjusting the pH value of the remaining electrolyte containing indium gallium to 1, using a P204 extractant to obtain an indiu...

Embodiment 3

[0079] Put the copper indium gallium selenium waste into a vacuum furnace for distillation. The vacuum degree of the vacuum furnace is 10Pa, the distillation temperature is 450°C, and the distillation time is 2.3 hours. Selenium and distillation waste are obtained through separation by a condenser; the purity of the selenium powder is >99.9 %, recovery > 99%;

[0080] The above-mentioned distillation waste is used as the anode, and the stainless steel plate is used as the cathode. In the electrolytic cell, the distillation waste is dissolved in copper sulfate electrolyte for electrolysis. The voltage of the electrolytic cell is 0.35V, the electrolysis temperature is 35°C, and the current density is 250A / m 2 , depositing copper in the cathode, and obtaining the remaining electrolyte containing indium gallium; wherein, the purity of copper is >99.99%;

[0081] Adjusting the pH value of the remaining electrolyte solution containing indium gallium to 0.2, using a P204 extractant t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com