Heat-resistant anti-aging SBS modified asphalt waterproof coiled material

A technology for modifying asphalt and waterproofing membranes, which is used in building thermal insulation materials, building components, buildings, etc., can solve the problems of poor hardness and physical strength of waterproof coating films, inability to further swell and modify, and stress concentration in waterproof building materials. Achieve the effect of improving self-cleaning ability, improving load efficiency, and improving weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

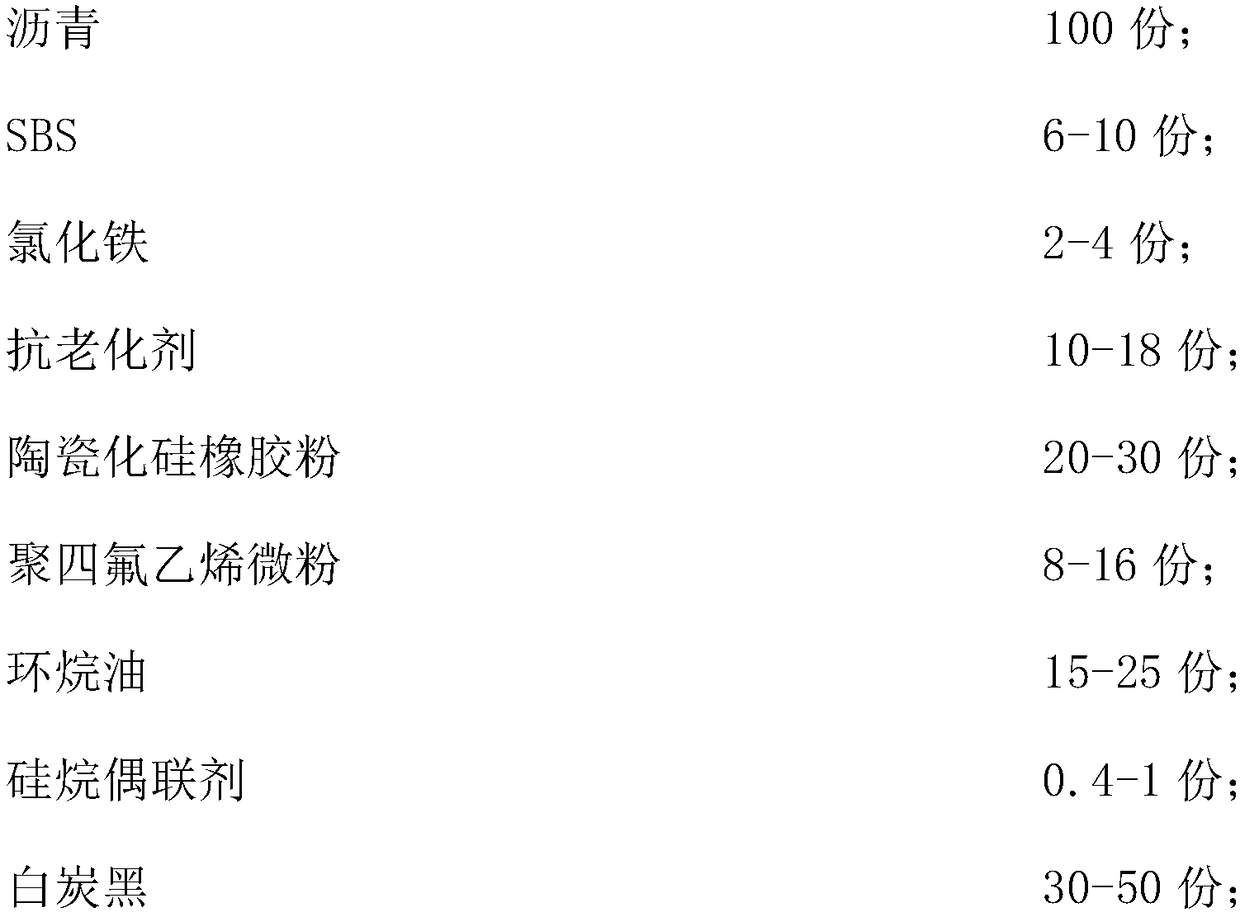

[0023] A heat-resistant and anti-aging SBS modified asphalt waterproof membrane, comprising the following raw materials in parts by weight:

[0024]

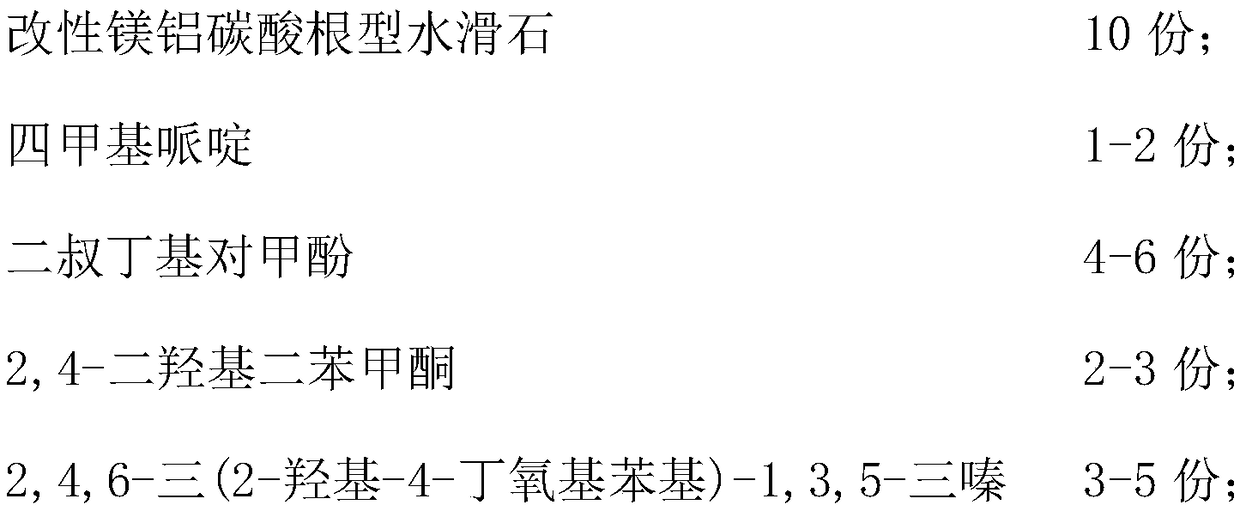

[0025] Wherein, anti-aging agent comprises following components by weight:

[0026]

[0027]

[0028] The present invention also provides a method for preparing the above-mentioned heat-resistant and anti-aging SBS modified asphalt waterproofing membrane, comprising the following steps:

[0029] S1: Treat the magnesium aluminum carbonate hydrotalcite with 0.02mol / L boric acid for 1-2 hours, then repeatedly suction-filtered to neutral pH, and calcined at 150°C under argon until the interlayer moisture content is ≤2%, and then Modified magnesium aluminum carbonate hydrotalcite and nano-titanium dioxide were added with tetramethylpiperidine, di-tert-butyl-p-cresol, 2,4-dihydroxybenzophenone, 2,4,6-tris(2-hydroxy- In the mixed solution of 4-butoxyphenyl)-1,3,5-triazine, ultrasonically disperse until the mixed solution and ...

Embodiment 2

[0033] A heat-resistant and anti-aging SBS modified asphalt waterproof membrane, comprising the following raw materials in parts by weight:

[0034]

[0035]

[0036] Wherein, anti-aging agent comprises following components by weight:

[0037]

[0038] The preparation method of above-mentioned waterproof coiled material is with embodiment 1, difference is:

[0039] S1: Boric acid treatment for 1.5 hours, the calcination temperature is 165°C;

[0040] S2: The mixing temperature and time are 175°C and 4h, respectively;

[0041] S3: The coating thickness on one side is 0.8mm.

Embodiment 3

[0043] A heat-resistant and anti-aging SBS modified asphalt waterproof membrane, comprising the following raw materials in parts by weight:

[0044]

[0045] Wherein, anti-aging agent comprises following components by weight:

[0046]

[0047] The preparation method of above-mentioned waterproof coiled material is with embodiment 1, difference is:

[0048] S1: Boric acid treatment for 2 hours, the calcination temperature is 180°C;

[0049] S2: The mixing temperature and time are 185°C and 5h respectively;

[0050] S3: The coating thickness on one side is 1.2 mm.

[0051] Taking ordinary SDS modified asphalt coils as a comparative example, the mechanical properties and stability of Examples 1-3 and comparative examples were tested respectively, and the results are shown in the following table:

[0052]

[0053] It can be seen from the above table that the present invention obviously improves the comprehensive performance of the waterproof membrane, and the produced ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com