Comprehensive treatment method for harmless recycling of pickling sludge and pickling waste liquid

A technology for pickling waste liquid and pickling sludge, applied in the directions of iron oxide/iron hydroxide, iron oxide, etc., can solve the problems of complex metal composition, difficult extraction, unscientific and non-standard disposal methods, etc., and achieve simple process operation. , production safety and environmental protection, the effect of product morphology specification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

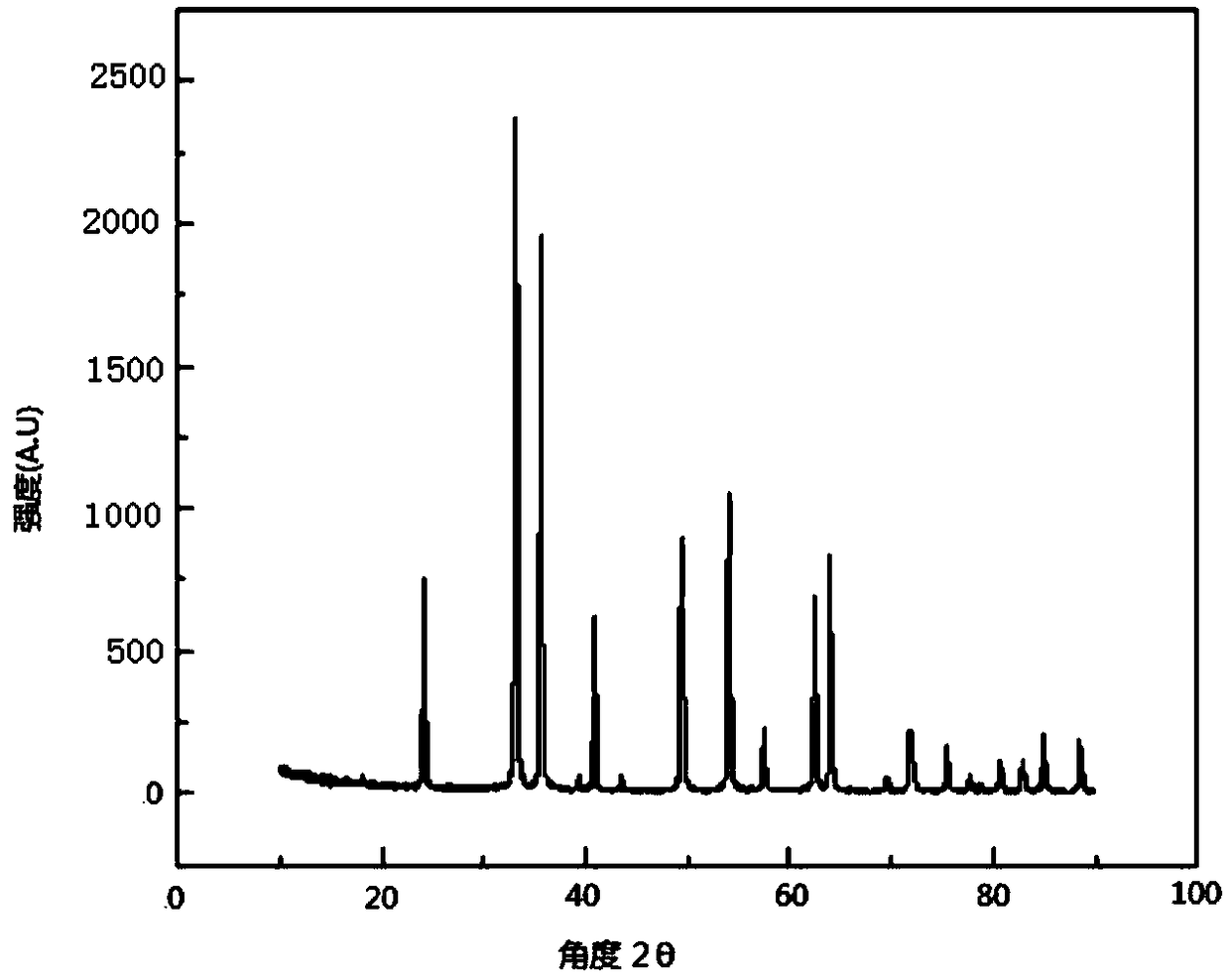

Image

Examples

Embodiment 1

[0036] A method for harmless and resourceful comprehensive treatment of pickling sludge and pickling waste liquid, comprising the following steps:

[0037] (1) Mix 30g of hydrochloric pickling sludge with 150ml of pickling waste solution with a hydrochloric acid concentration of 3mol / L, stir at 60°C for 30min, cool to room temperature, filter to obtain filter cake and filtrate, and dry the filter cake to make building materials use;

[0038] (2) by the ratio of 100ml:2g, add waste iron scale in the filtrate that step (1) obtains, stir evenly, place 10h at normal temperature, solid-liquid separation, solid is used as the waste iron scale of next processing step (2);

[0039] (3) in the ratio of 100ml:4g, add scrap iron filings in the filtrate that step (2) obtains, stir evenly, place 10h at normal temperature, solid-liquid separation, solid is used as the scrap iron filings of next processing step (3);

[0040] (4) Adjust the pH of the filtrate obtained in step (3) to 5, add p...

Embodiment 2

[0045] A method for harmless and resourceful comprehensive treatment of pickling sludge and pickling waste liquid, comprising the following steps:

[0046] (1) Mix 30g of hydrochloric pickling sludge with 300ml of pickling waste solution with a hydrochloric acid concentration of 2mol / L, stir at 80°C for 10 minutes, cool to room temperature, filter to obtain filter cake and filtrate, and dry the filter cake to make building materials use;

[0047] (2) In the ratio of 100ml:0.2g, add waste iron scale to the filtrate obtained in step (1), stir evenly, place at room temperature for 36h, separate the solid and liquid, and the solid is used as the waste iron scale of the next processing step (2);

[0048] (3) In the ratio of 100ml:0.1g, add iron scraps to the filtrate obtained in step (2), stir evenly, place at room temperature for 36h, separate the solid and liquid, and the solid is used as the scrap iron scraps of the next processing step (3);

[0049] (4) Adjust the pH of the fi...

Embodiment 3

[0054] A method for harmless and resourceful comprehensive treatment of pickling sludge and pickling waste liquid, comprising the following steps:

[0055] (1) Mix 30g of hydrochloric pickling sludge with 90ml of pickling waste solution with a hydrochloric acid concentration of 5mol / L, stir at 30°C for 120min, cool to room temperature, filter to obtain filter cake and filtrate, and dry the filter cake to make building materials use;

[0056] (2) in the ratio of 100ml:5g, add scrap iron sheet to the filtrate that step (1) obtains, stir evenly, place 2h at normal temperature, separate solid and liquid, and solid is used as the scrap iron sheet of next processing step (2);

[0057] (3) in the ratio of 100ml:5g, add scrap iron filings to the filtrate that step (2) obtains, stir evenly, place 2h at normal temperature, separate solid and liquid, and solid is used as the scrap iron filings of next processing step (3);

[0058] (4) Adjust pH=8 in the filtrate obtained in adjustment s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com