Low-density sound-absorbing and insulating polymer composite material and preparation method thereof

A composite material and polymer technology, applied in the field of polymer composite materials, can solve the physical and mental health hazards of drivers and urban residents, and the problems of polymer composite materials that have not been seen yet, achieve good sound absorption and insulation performance, and simple production process , The effect of less equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

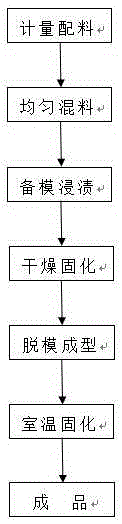

[0045] A preparation method for producing a low-density sound-absorbing and insulating polymer composite material, which is carried out as follows:

[0046] ① Measuring ingredients:

[0047] First select the raw material:

[0048] The raw material of epoxy resin is bisphenol A epoxy resin, which has a viscosity of 12500mPa·s at 25°C and an epoxy equivalent of 189g / eq;

[0049] Polyetheramine EC311 is used as the raw material of curing agent;

[0050] Acetone is selected as the raw material of the resin diluent, and its normal pressure boiling point is 56.5°C;

[0051] Glass fiber cotton is made of extra-fine glass fiber cotton with a glass fiber diameter of 4.5 μm.

[0052] Then weigh the raw materials respectively according to the following weight ratio:

[0053] 100 parts of bisphenol A type epoxy resin,

[0054] Polyetheramine EC31130 parts,

[0055] 35 parts of acetone,

[0056] 30 parts of superfine glass fiber cotton raw materials with a glass fiber diameter of 4....

Embodiment 2

[0063] A preparation method for producing a low-density sound-absorbing and insulating polymer composite material, which is carried out as follows:

[0064] ① Measuring ingredients:

[0065] First select the raw material:

[0066] The raw material of epoxy resin is bisphenol F epoxy resin, which has a viscosity of 800mPa·s at 25°C and an epoxy equivalent of 280g / eq;

[0067] The raw material of the curing agent is oligomeric polyamide 650;

[0068] The raw material of the resin diluent is ethanol, whose boiling point at normal pressure is 78.4°C;

[0069] Glass fiber cotton is made of extra-fine glass fiber cotton with a glass fiber diameter of 8.0 μm.

[0070] Then weigh the raw materials respectively according to the following weight ratio:

[0071] 100 parts of bisphenol F type epoxy resin,

[0072] Oligopolyamide 65020 parts,

[0073] 10 parts of ethanol,

[0074] 6 parts of superfine glass fiber cotton raw materials with a glass fiber diameter of 8.0 μm.

[0075] ...

Embodiment 3

[0081] A preparation method for producing a low-density sound-absorbing and insulating polymer composite material, which is carried out as follows:

[0082] ① Measuring ingredients:

[0083] First select the raw material:

[0084] The raw material of epoxy resin is o-cresol novolac epoxy resin, which has a viscosity of 27000mPa·s at 25°C and an epoxy equivalent of 220g / eq;

[0085] The raw material of the curing agent is cycloaliphatic amine EC331;

[0086] The raw material of the resin diluent is toluene, and its normal pressure boiling point is 110.6°C;

[0087] Glass fiber cotton is made of extra-fine glass fiber cotton with a glass fiber diameter of 1.5 μm.

[0088] Then weigh the raw materials respectively according to the following weight ratio:

[0089] 100 parts of o-cresol novolac epoxy resin,

[0090] Cycloaliphatic amine EC33150 parts,

[0091] 95 parts of toluene,

[0092] 120 parts of superfine glass fiber cotton raw materials with a glass fiber diameter of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com