Semi-conductor surface emitting laser and production method and applications thereof

A surface emitting laser, semiconductor technology, applied in semiconductor lasers, lasers, laser parts and other directions, can solve the problems of reducing device life and reliability, difficult heat dissipation, device life and stability effects, etc., to improve working life and Work reliability, improve heat dissipation performance, improve the effect of heat dissipation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

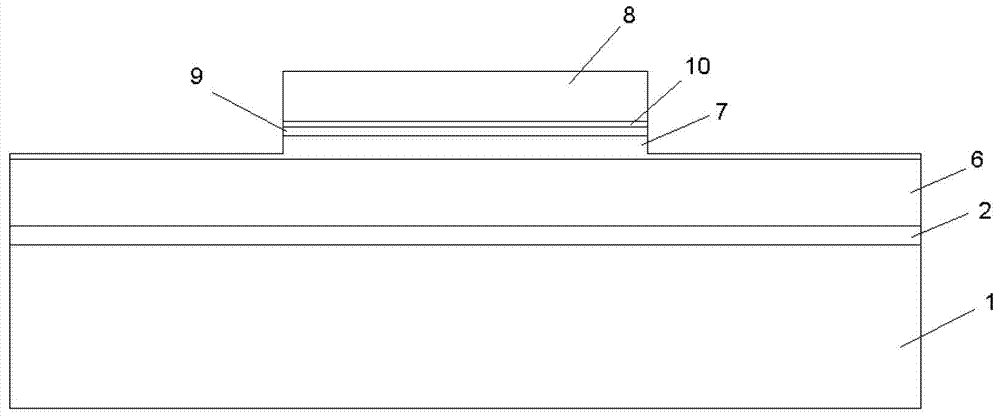

[0049] A semiconductor surface-emitting laser, comprising a sequentially connected substrate layer 1, an N-type GaAs buffer layer 2, a lower distributed Bragg reflector DBR layer 6, an upper layer 7 of the lower distributed Bragg reflector DBR layer, and an active layer 9 , an oxidized current confinement layer 10 and an upper DBR layer 8; the buffer layer 2 is provided with an N-type electrode 4, and the upper DBR layer 8 is provided with a P-type electrode 12; the oxidized current confinement layer 10 is provided with There is a light outlet 11; the lower DBR layer 6 uses binary N-type AlAs / GaAs pairs; the number of binary N-type AlAs / GaAs pairs in the lower distributed Bragg reflector DBR layer 6 is thirty pairs; the The diameter of the light exit hole 11 is 14-18 μm; the upper layer of the lower distributed Bragg reflector DBR layer 6 is a ternary N-type distributed Bragg reflector DBR layer, and the upper distributed Bragg reflector DBR layer 8 is three Element P-type dis...

Embodiment 2

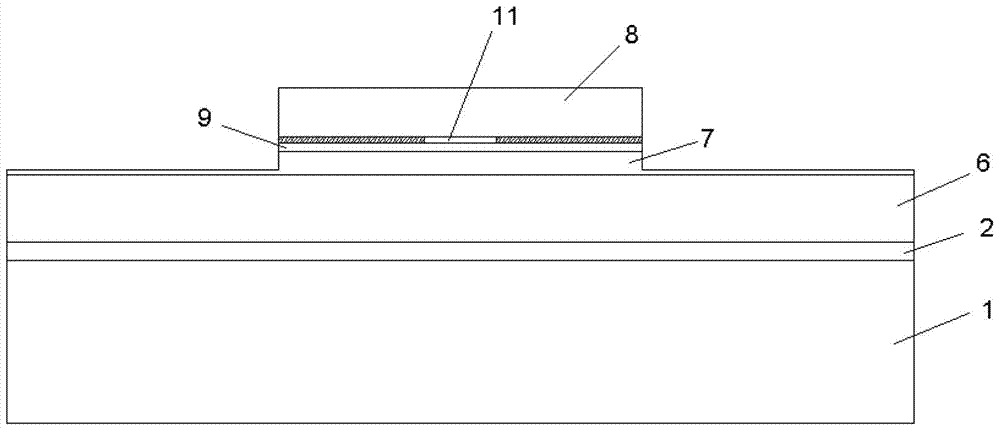

[0051] A semiconductor surface-emitting laser, comprising a substrate layer 1, a buffer layer 2, a lower distributed Bragg reflector DBR layer 6, an upper layer 7 of the lower distributed Bragg reflector DBR layer, an active layer 9, an oxidized The current confinement layer 10 and the upper distributed Bragg reflector DBR layer 8; the buffer layer 2 is provided with an N-type electrode 4, and the upper distributed Bragg reflector DBR layer 8 is provided with a P-type electrode 12; the oxidation The current confinement layer 10 is provided with a light exit hole 11; the diameter of the light exit hole 11 is 14-18 μm; the lower distributed Bragg reflector DBR layer 6 uses a binary N-type AlAs / GaAs pair; the lower distributed The number of binary N-type AlAs / GaAs pairs in the DBR layer 6 of the Bragg reflector is thirty pairs; well; the entire thickness of the active layer 9 is a length of λ; the substrate layer 1 is a semi-insulating GaAs substrate layer; the buffer layer 2 is ...

Embodiment 3

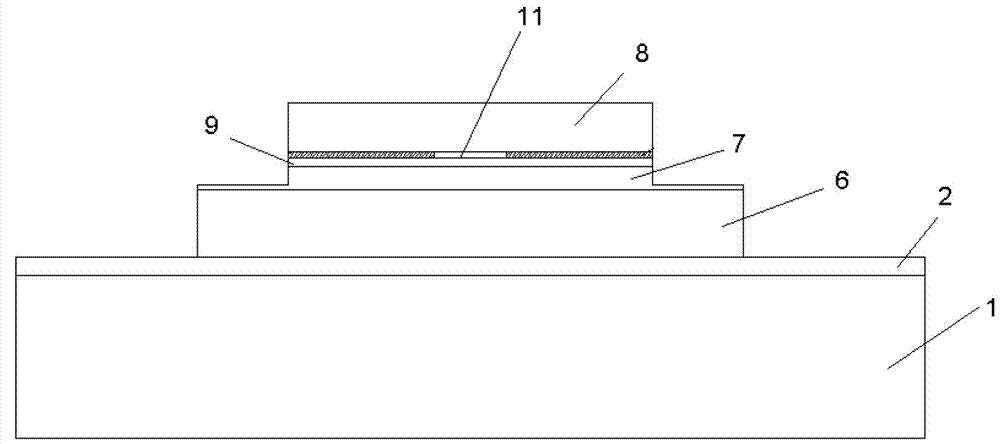

[0053] A semiconductor surface-emitting laser, comprising a substrate layer 1, a buffer layer 2, a lower distributed Bragg reflector DBR layer 6, an upper layer 7 of the lower distributed Bragg reflector DBR layer, an active layer 9, an oxidized A current confinement layer 10 and an upper DBR layer 8; the buffer layer 2 is provided with an N-type electrode 4, and the upper distributed Bragg reflector DBR layer 8 is provided with a P-type electrode 12; the oxidized current confinement layer 10 A light exit hole 11 is provided on the top; the diameter of the light exit hole 11 is 14-18 μm; the lower DBR layer 6 adopts a binary N-type AlAs / GaAs pair; the binary N-type AlAs / GaAs pair of the lower DBR layer 6 The number is thirty pairs; the buffer layer 2, the lower distributed Bragg reflector DBR layer 6, the upper layer 7 of the lower distributed Bragg reflector DBR layer, the active layer 9, the oxidized current confinement layer 10 and the upper distributed The upper and side s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com