Double-pipe radiating pipe for radiator

A technology for heat dissipation pipes and radiators, applied in tubular components, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of low heat dissipation efficiency, low pressure, poor corrosion resistance, etc., achieve improved corrosion resistance and facilitate cleaning , Increase the effect of structural strength and bearing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

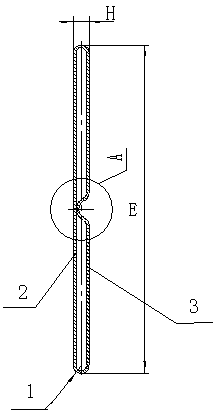

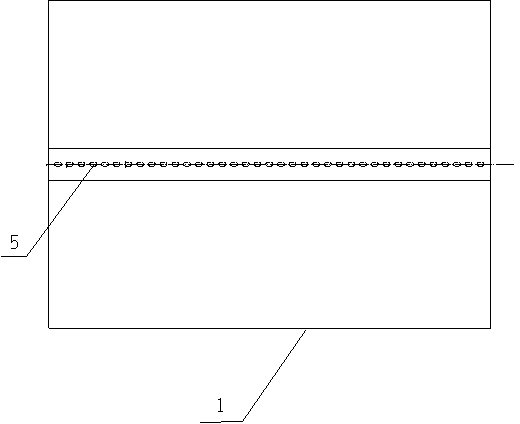

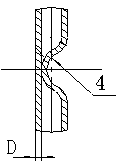

[0010] From figure 1 Schematic diagram showing the structure of the present invention, figure 2 From the right view, it can be seen that the present invention is a heat sink with a new structure, which is a high-frequency welded B-type heat sink. The aluminum foil material is formed by high-frequency welding after forming. There is an inward depression 4 in the middle of one side of the heat dissipation pipe 1, and a row of welding holes 5 at the top of the depression 4, which can be waist holes or round holes, and the depression 4 divides the heat dissipation pipe 1 into upper and lower double pipes. image 3 for figure 1 The partial schematic diagram marked A in the middle. From the cross-sectional shape, the left side 2 of the radiating pipe is a straight line, and the middle part of the right side 3 of the radiating pipe is recessed inward. The cross-sectional shape is "B". The recess 4 connects the two sides together, so that The upper and lower double pipes form independe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com