A graphene metal composite multilayer heat sink with high thermal conductivity and preparation method thereof

A metal composite, graphene technology, applied in lighting and heating equipment, semiconductor devices of light-emitting elements, coatings, etc., can solve the problems of reducing the heat dissipation effect of graphene composite materials, uneven dispersion of graphene, unfavorable heat dissipation performance, etc. Achieve the effect of reducing temperature, low cost, solving trend inconsistency and uneven distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

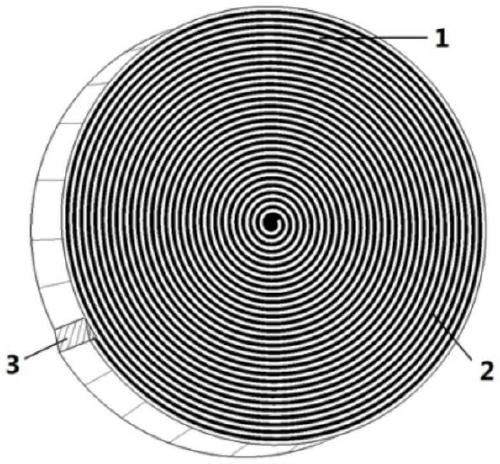

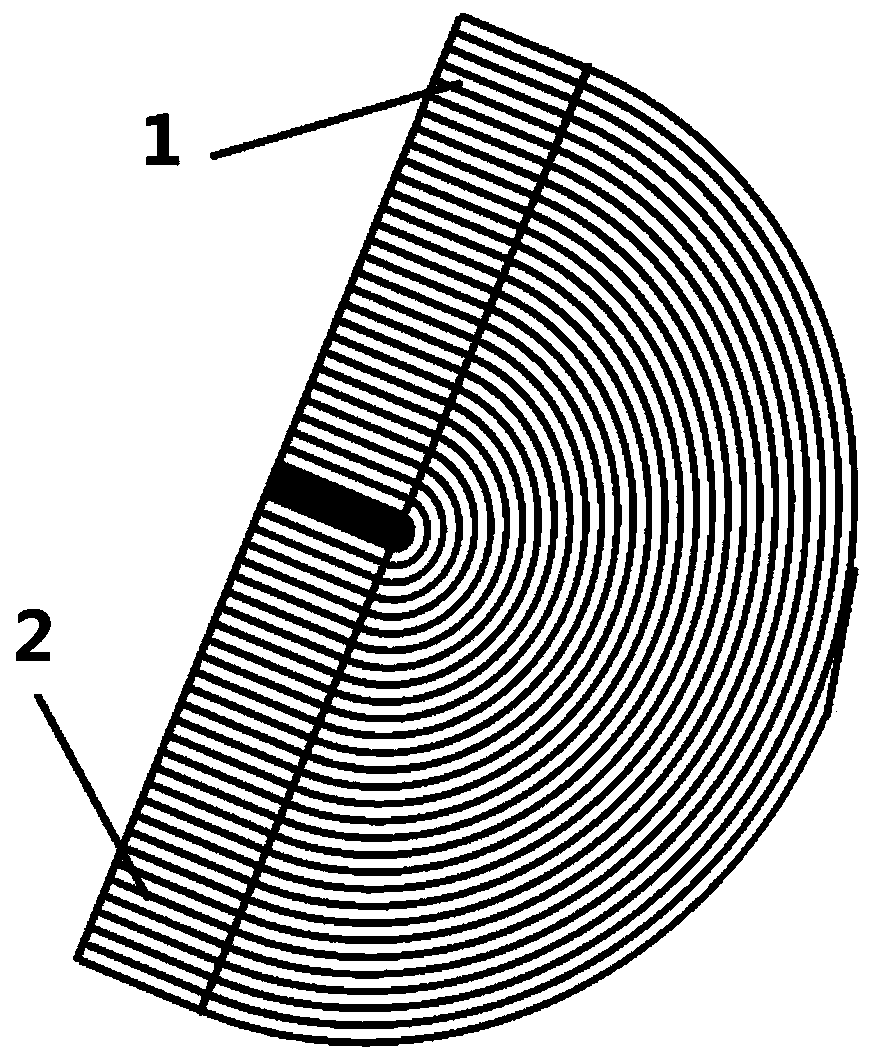

[0031]The graphene metal composite multilayer radiator with high thermal conductivity of the present invention comprises a metal base layer 1 , a graphene film layer 2 and a welding part 3 . The metal base layer 1 is composed of a strip-shaped aluminum sheet with a thickness of 1 mm. A layer of the graphene film layer 2 is uniformly deposited on the surface of the strip-shaped aluminum sheet, and its thickness is equal to that of single-layer or few-layer graphene. The welding part 3 is located on the outer side of the graphene-aluminum composite multilayer heat sink with high thermal conductivity. The graphene-aluminum composite multilayer heat sink with high thermal conductivity of the present invention is formed by tightly rolling the strip-shaped aluminum sheet and the graphene film layer 2 evenly deposited on the surface of the strip-shaped aluminum sheet into a round cake shape And constituted, inside the heat sink, the strip-shaped aluminum sheets and the graphene film...

Embodiment 2

[0036] The graphene metal composite multilayer heat sink with high thermal conductivity in this embodiment includes a metal base layer 1 , a graphene film layer 2 and a welding part 3 . The metal base layer 1 is composed of a strip-shaped aluminum alloy sheet with a thickness of 0.05 mm. A layer of the graphene film layer 2 is uniformly deposited on the surface of the strip-shaped aluminum alloy sheet, and its thickness is equal to that of single-layer or few-layer graphene. The welding part 3 is located on the outer side of the graphene-aluminum composite multilayer heat sink with high thermal conductivity. The graphene aluminum alloy composite multilayer heat sink with high thermal conductivity of the present invention is formed by tightly rolling the strip-shaped aluminum alloy sheet and the graphene film layer 2 evenly deposited on the surface of the strip-shaped aluminum alloy sheet. In the interior of the radiator, the strip-shaped aluminum alloy sheets and the graphene...

Embodiment 3

[0041] The graphene metal composite multilayer heat sink with high thermal conductivity in this embodiment includes a metal base layer 1 , a graphene film layer 2 and a welding part 3 . The metal base layer 1 is composed of a strip-shaped copper sheet with a thickness of 0.1 mm. A layer of graphene film layer 2 is uniformly deposited on the surface of the strip-shaped copper sheet, and its thickness is equal to that of single-layer or few-layer graphene. The welding portion 3 is located outside the graphene-copper composite multilayer heat sink with high thermal conductivity. The high thermal conductivity graphene copper composite multilayer heat sink of the present embodiment is that the strip copper sheet and the graphene thin film layer 2 uniformly deposited on the surface of the strip copper sheet are tightly rolled into a round cake inside the heat sink, the strip-shaped copper sheets and the graphene film layers 2 are stacked alternately to form a helical multilayer com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com