Surface tack thermistor element

A thermistor element, surface adhesion technology, applied in the direction of resistors with negative temperature coefficient, resistors with positive temperature coefficient, etc., can solve the problem of poor heat transfer, inability to increase maintenance current, low sensitivity to ambient temperature, etc. problems, to achieve the effect of improving material properties, increasing maintenance current, and increasing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the above-mentioned and other technical content, features and advantages of the present invention more obvious and understandable, the following specifically cites relevant embodiments, together with the attached drawings, for detailed description as follows:

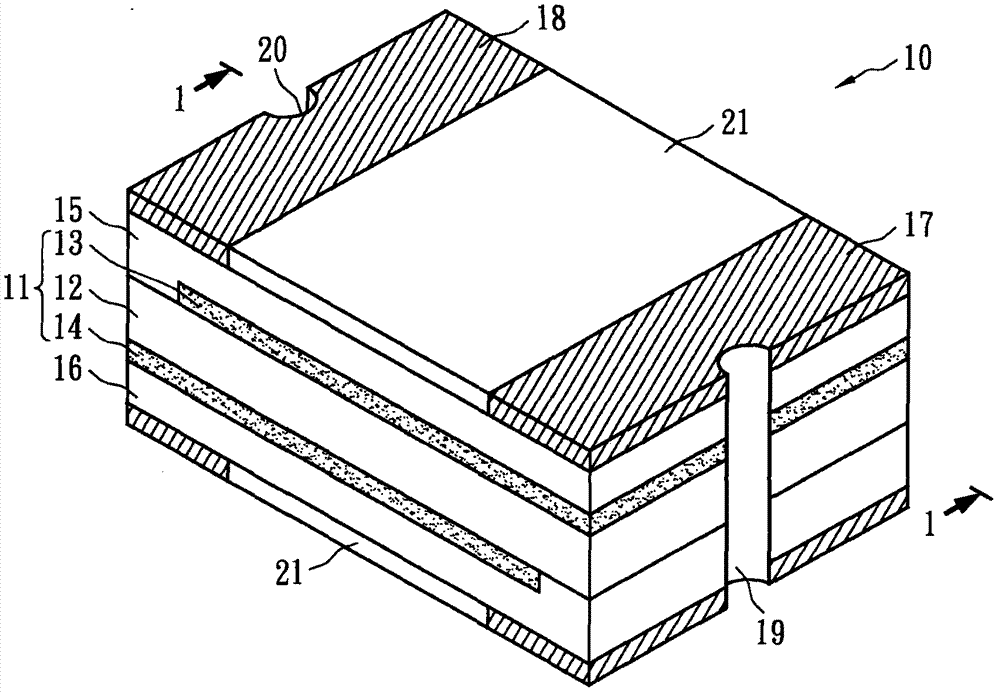

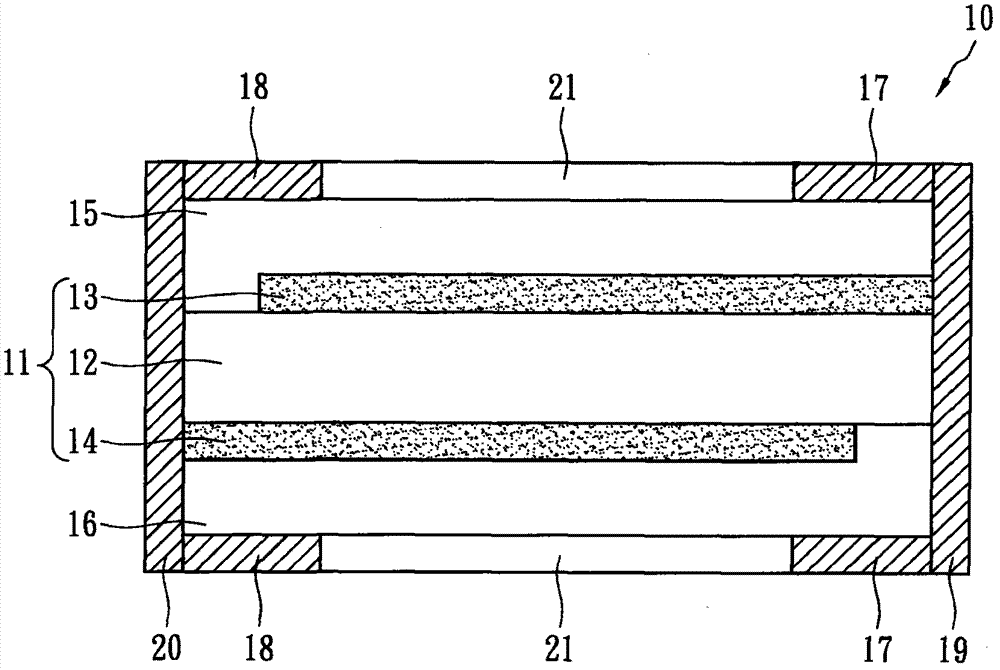

[0030] figure 1 A surface mount type thermistor element 10 showing a first embodiment of the present invention, figure 2 for figure 1 Schematic diagram of the cross-sectional structure along section line 1-1. The surface mount type thermistor element 10 includes a resistance element 11 , a first electrode 17 , a second electrode 18 , thermally conductive insulating layers 15 and 16 , a first conductive member 19 and a second conductive member 20 . The resistor element 11 includes a first conductive member 13 , a second conductive member 14 and a polymer material layer 12 . The polymer material layer 12 is stacked between the first conductive member 13 and the second conductive member 14, that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com