Preparation and use method of low-temperature cellulase

A low-temperature cellulase and cellulase technology, applied in the biological field, can solve the problems of low fermentation temperature, environmental secondary pollution, singleness, etc., and achieve the effects of low growth temperature, no secondary pollution, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Detection of the cellulase activity of the low temperature cellulase

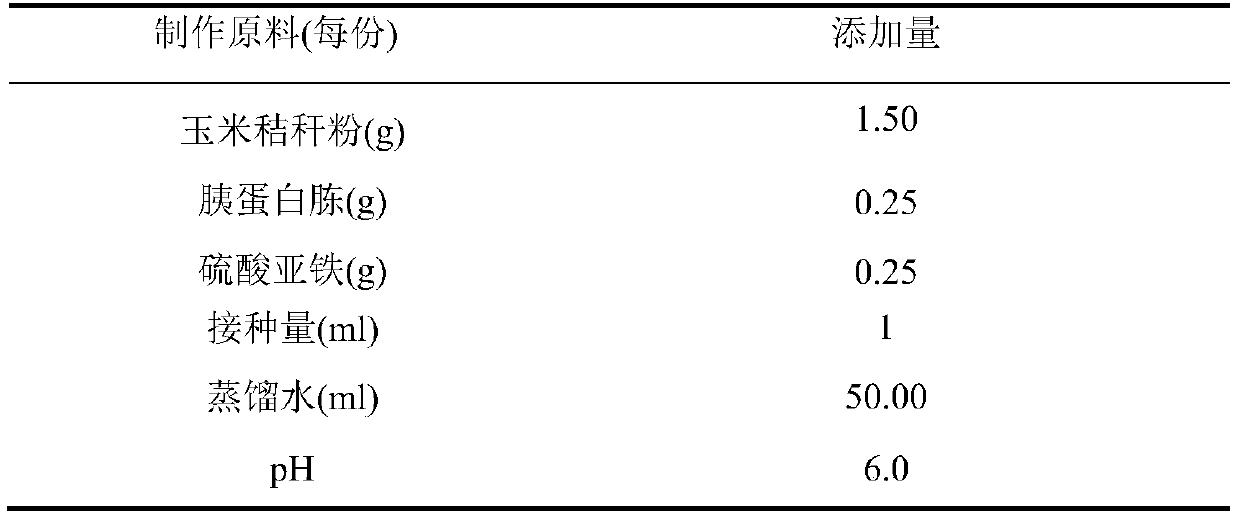

[0046] In order to explore the production of cellulase produced by the strain under the current conditions, insert Bacillus cereus into the culture medium under the above conditions to ferment and produce enzymes according to the above conditions, and do three parallel groups. After the fermentation, take fresh fermentation broth at 4°C Centrifuge at 10000r / min for 10min, and the supernatant obtained by centrifugation is the low-temperature cellulase enzyme solution of the strain; the enzyme activity of the cellulase in the enzyme solution is measured by 3,5-dinitrosalicylic acid colorimetry, and the enzyme activity is expressed as 1mL of cellulase solution catalyzes the substrate to generate 1.0μg of glucose in 1min, which is an enzyme activity unit. The measurement results are shown in Table (2).

[0047] Table 2)

[0048]

[0049] As can be seen from the measurement results in Table (2), when...

Embodiment 2

[0051] Determination of Enzymatic Properties of Low Temperature Cellulase

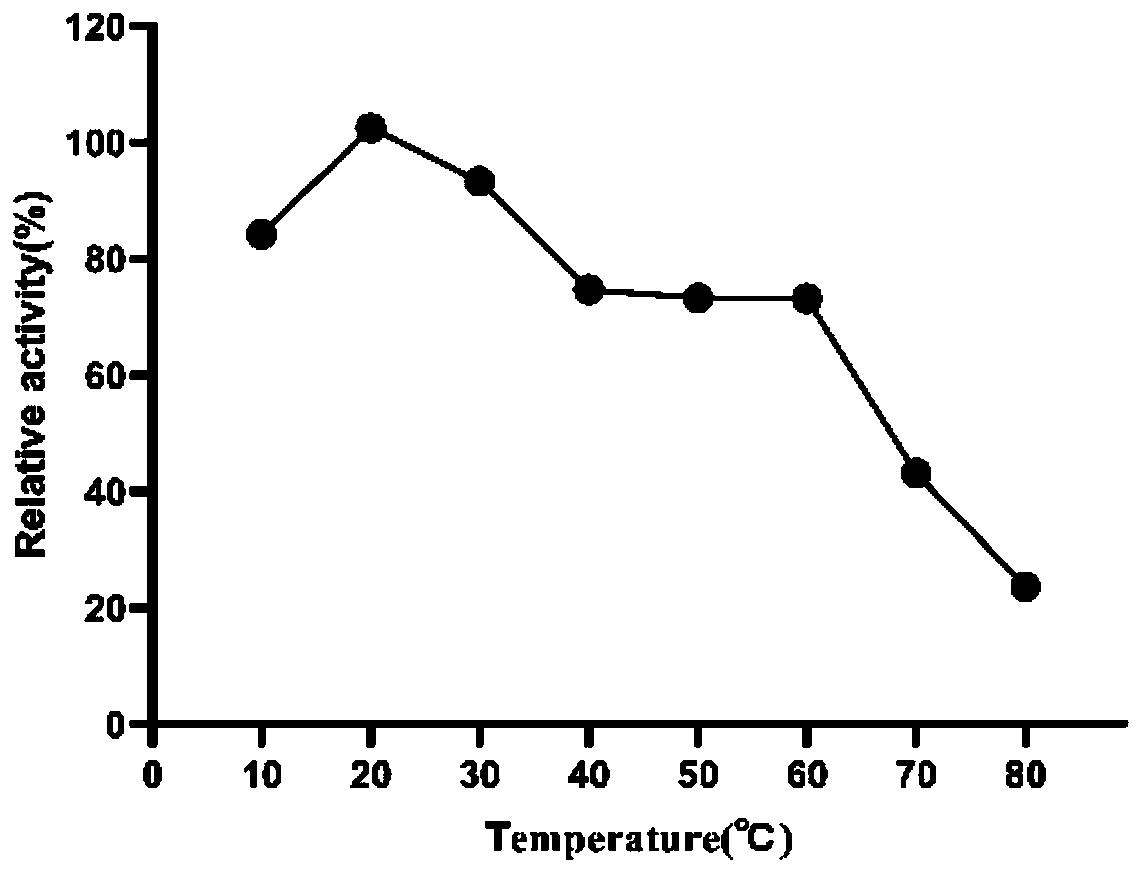

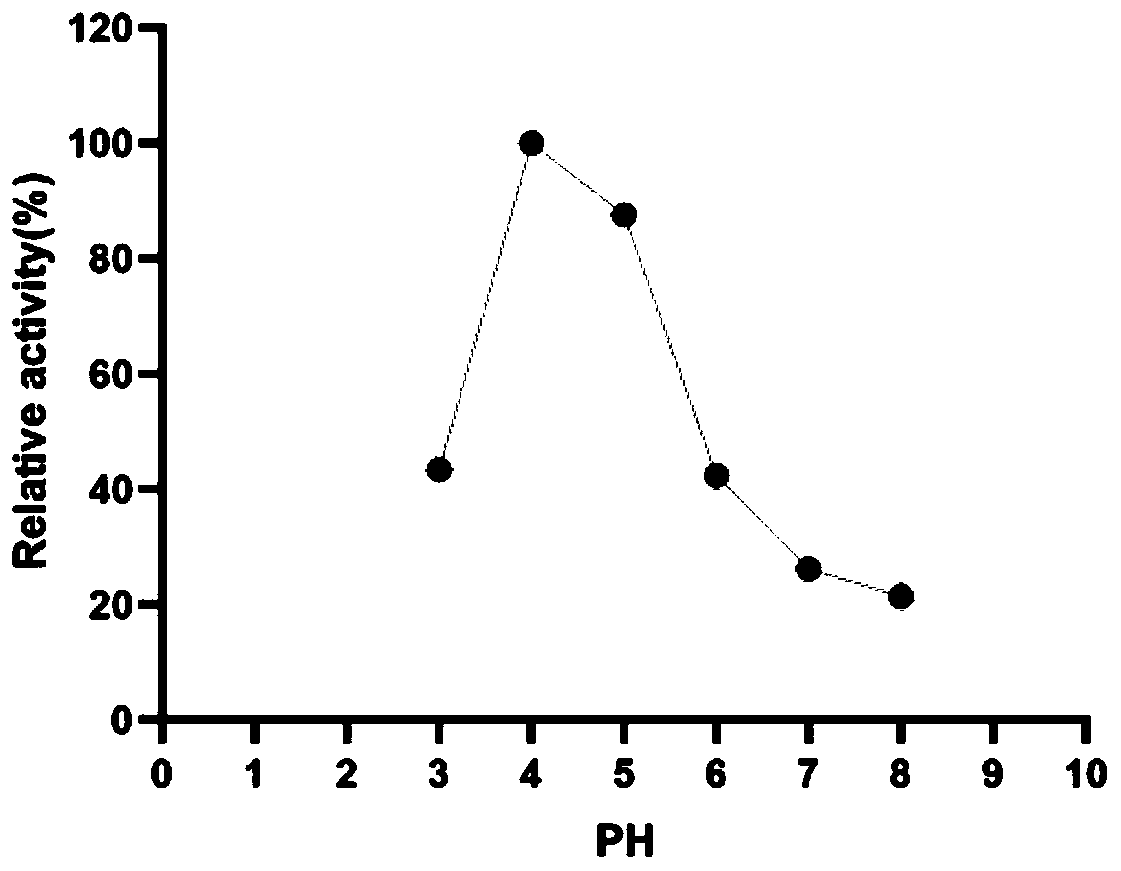

[0052] The enzymatic activity of the obtained cellulase liquid is measured, and the stability of the cellulase liquid to temperature and pH is measured respectively, so as to determine the application conditions of the cellulase. Place the crude enzyme solution obtained by centrifugation at 10°C, 20°C, 30°C, 40°C, 45°C, 50°C, 60°C, 70°C, 80°C, and 90°C and incubate for 60 minutes, and measure the enzyme activity after rapid cooling. The untreated crude enzyme is 100% and calculates the remaining enzyme activity percentage, the result is as follows figure 1 shown. Adjust the crude enzyme solution obtained by centrifugation to different pH (3-8), incubate at 4°C for 60 minutes, calculate the percentage of remaining enzyme activity with the untreated crude enzyme as 100%, and the result is as follows figure 2 shown.

[0053] like figure 1 As shown, the cellulase activity is measured after the crude e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com