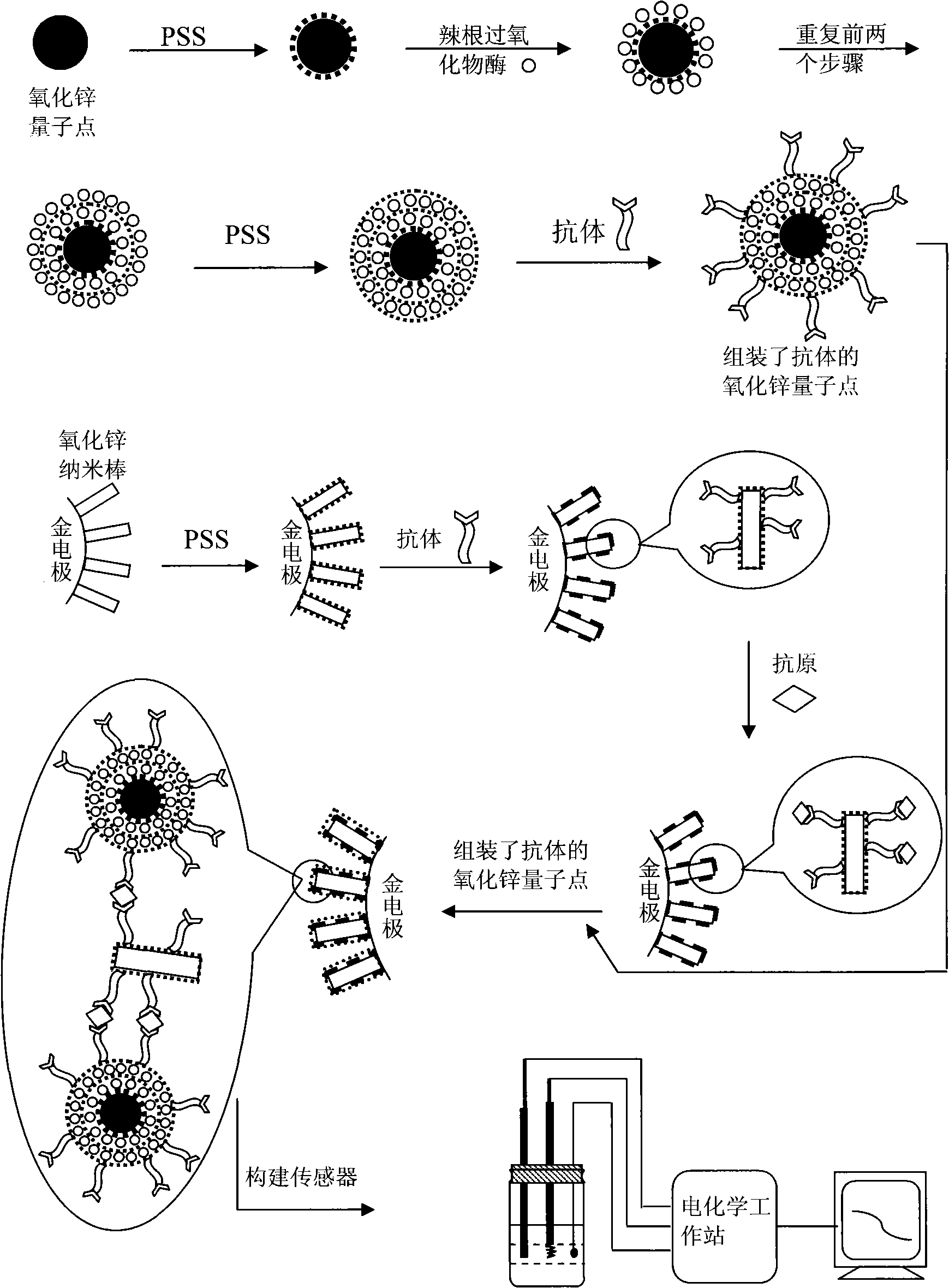

Method for immunoassay by utilizing zinc oxide quantum dots

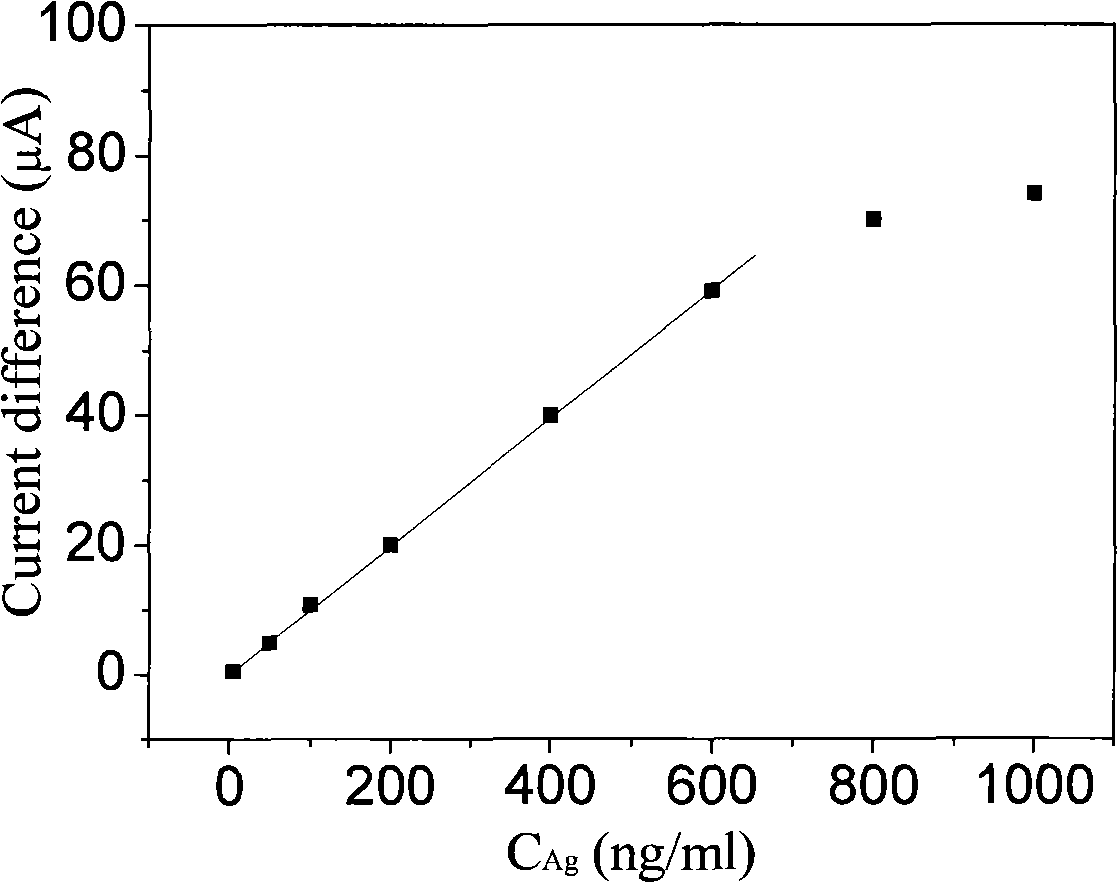

An immunoassay and quantum dot technology, which is applied to the electrochemical variables of materials, material analysis through electromagnetic means, and measurement devices, can solve the problems of delaying disease discovery and optimal treatment timing, long cycle, and poor accuracy. The effect of shortening the detection time, low detection limit, and lower detection limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Step 1: Burn one end of a gold wire or platinum wire to form a small ball, then vapor-deposit a layer of zinc with a thickness of about 200 nanometers on the surface of the ball, put it in a tube furnace for oxidation at about 300°C for 1 hour, and take it out Boil with 2M KOH for 2 hours, take it out, wash it with deionized water, and place it in a place containing 30% (volume ratio) H 2 o 2 H 2 SO 4 After 30 minutes, it was taken out, washed with deionized water, and dried at room temperature.

[0029] The second step: mix the zinc powder and deionized water for 20 minutes, let it stand for 30 minutes, pour off the water, transfer the zinc powder and water to the autoclave according to 1:100 (mass ratio), and let it stand until there is no suspension Granules, the gold or platinum treated in the first step is immersed in water without touching the zinc powder at the bottom of the autoclave. Sealed so that it can withstand a maximum pressure of not less than 1.5×10...

Embodiment 2

[0038] Step 1: Melt one end of a gold wire with a diameter of 0.5 mm into a small ball with a diameter of about 1.2 mm, evaporate a layer of zinc with a thickness of about 200 nanometers on the surface of the ball, put it in a tube furnace at 300 ° C to oxidize 1 hours, take it out and boil it with 2M KOH for 2 hours, take it out and wash it with deionized water, and then place it in a place containing 30% H 2 o 2 H 2 SO 4 (volume ratio) after 30 minutes, take it out, and then wash it with deionized water.

[0039] The second step: mix the zinc powder and deionized water for 20 minutes, let it stand for 30 minutes, pour off the water, transfer the zinc powder and water to the autoclave according to 1:100 (mass ratio), and let it stand until there is no suspension Granules, the gold wire treated in the first step is immersed in water without touching the zinc powder at the bottom of the autoclave. Sealed so that it can withstand a maximum pressure of not less than 1.5×10 5...

Embodiment 3

[0048] Step 1: Melt one end of a gold wire with a diameter of 0.5 mm into a small ball with a diameter of about 1.2 mm, evaporate a layer of zinc with a thickness of about 200 nanometers on the surface of the ball, put it in a tube furnace at 300 ° C to oxidize 1 hours, take it out and boil it with 2M KOH for 2 hours, take it out and wash it with deionized water, and then place it in a place containing 30% H 2 o 2 H 2 SO 4 (volume ratio) after 30 minutes, take it out, and then wash it with deionized water.

[0049] The second step: mix the zinc powder and deionized water for 20 minutes, let it stand for 30 minutes, pour off the water, transfer the zinc powder and water to the autoclave according to 1:100 (mass ratio), and let it stand until there is no suspension Granules, immerse the gold wire treated in the first step in water without touching the zinc powder at the bottom. Seal and heat to 90°C for 12 hours. Cool naturally to room temperature, take it out, and wash it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com