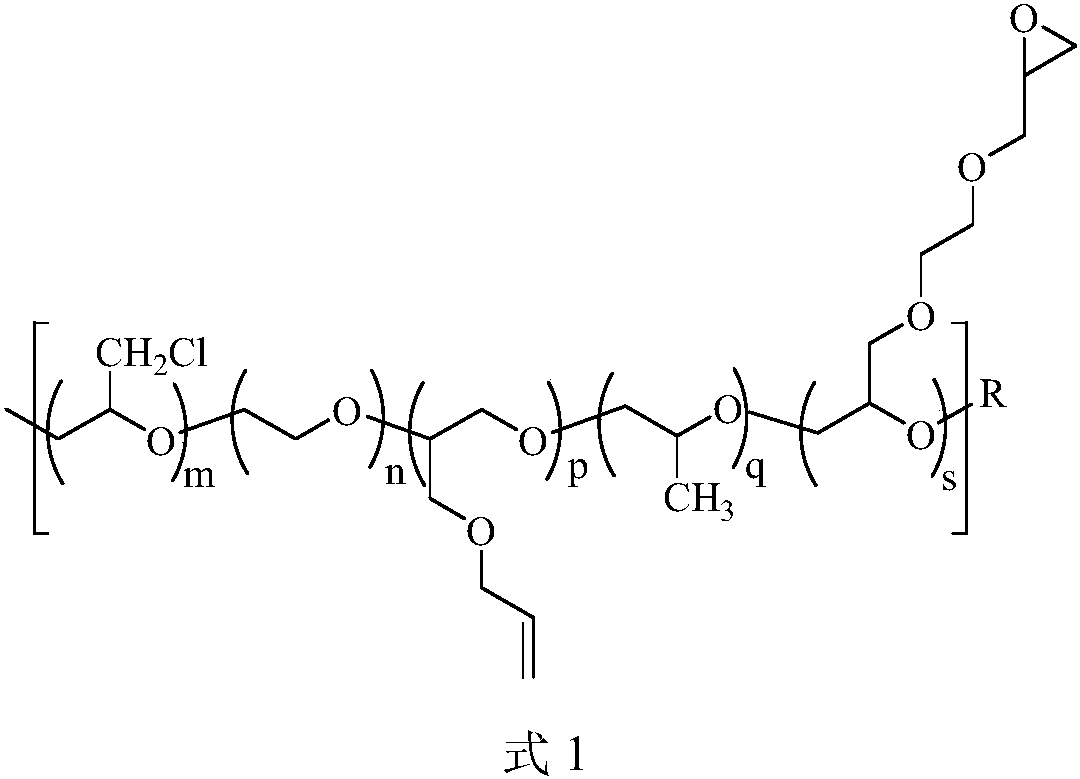

Tread rubber material for reducing tire rolling resistance as well as tread rubber and preparation method thereof

A technology of rolling resistance and tread rubber, which is applied in the direction of rolling resistance optimization, special tires, tire parts, etc., can solve the problems of tire heat generation is not obvious, the manufacturing process is complicated, and the payne effect is high, achieving high amorphous structure content, Effects of reduced fuel consumption and low content of crystalline block units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] Catalyst complex preparation:

[0101] Place the 200mL two-necked ox-horn bottle replaced with dry nitrogen into an ice-water bath at -5~5°C, and then use a syringe to inject 110mL of 20% triethylaluminum, 23mL of ether, 1.6mL of water, and 10.2mL of acetylacetone. Pour it into a horn bottle (the above are the mass contents), and after 30 minutes of magnetic stirring, the catalyst complex can be completely reacted, wherein the aluminum content in the complex solution is 1.21mol / L.

[0102] Add cyclohexane 2900mL, epichlorohydrin 37.0g, ethylene oxide 8.8g, allyl glycidyl ether 20.8g, propylene oxide 185.6g and ethylene glycol diglycidyl ether into a 5L steel polymerization kettle 0.70g, then the temperature of the material in the polymerization kettle is raised to 75~85°C with a hot water bath, and at this moment, a syringe is used to inhale a mixture of triethylaluminum: ether: water: acetylacetone=1: 1.5: 0.5: 0.5 (mol ratio ) composed of catalyst complex 26mL (the a...

Embodiment 2

[0104] In embodiment 1, other process conditions are kept unchanged, only the catalyst is changed into a catalyst complex (wherein the catalyst complex ring The aluminum content in the hexane solution is 1.05mol / L), inhale 30mL with a syringe and add it to the polymerization kettle for reaction. The finally obtained random alternating unsaturated epoxy-epoxyether rubber has a Mooney viscosity of 68.

Embodiment 3

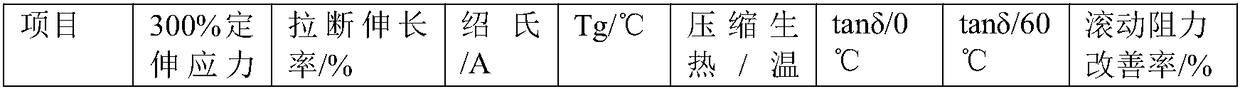

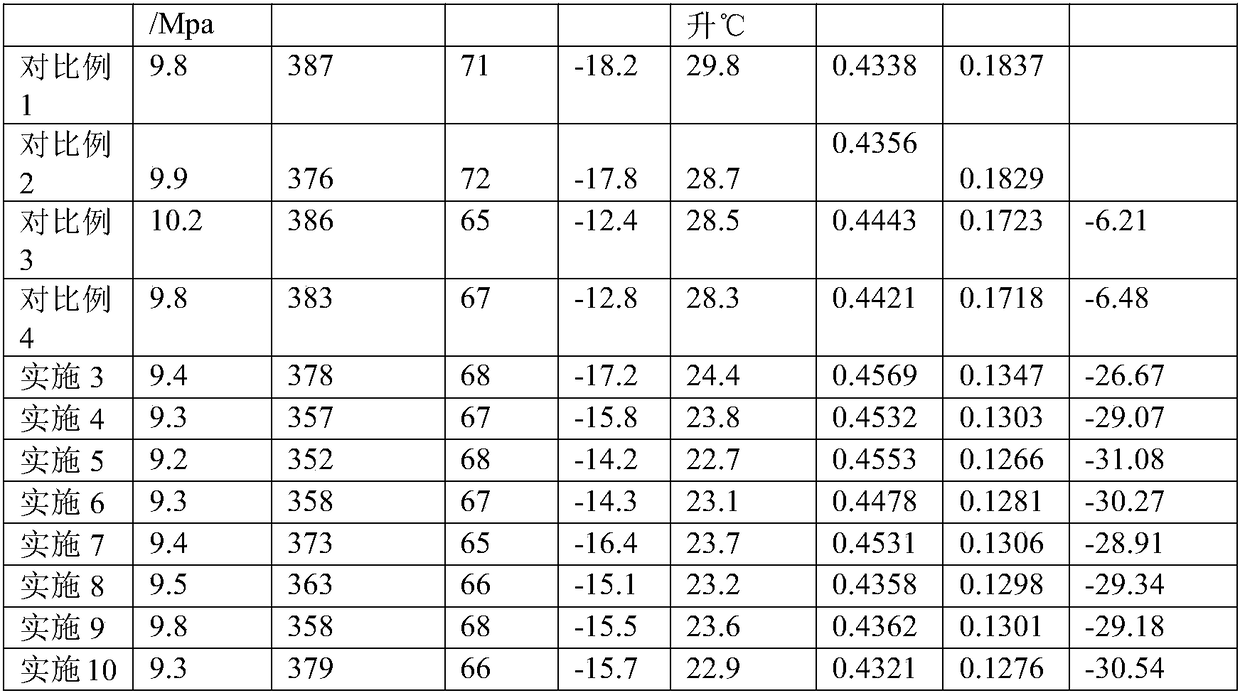

[0106]Preheat the 160×320 two-roll mill to 80-120°C. At this time, 15g of the unsaturated epoxy-ether chloride rubber prepared in Implementation 1, 112.5g of VSL5025-2HM (wherein, the oil content is 27.3wt%, ethylene Base content 63moL%, S / B=25 / 75), BR-9000 37.5g, dibutyl phthalate 7.5g into the two-roller mill, adjust the roller distance until the rubber material is broken and completely wrapped in the roller After that, mix 20g of TDAE oil and Si-69 10.5g into 90g of white carbon black, and add it to the mixed rubber on the mill in two times, and then put 10g of carbon black and 4.5g of zinc oxide on the roller , 2.25g of stearic acid, 3.0g of anti-aging agent 4020, 1.5g of anti-aging agent RD, and 1.5g of wax are added to the rubber material of the roller. Cool the masterbatch to room temperature. Next, put the masterbatch into the opened cooling mill, and put chilled water into it, control the roll temperature to 50-60°C, after the masterbatch is completely wrapped, put 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com