Halogen-free flame-retardant thermal-contraction material and method for preparing same

A technology of heat shrinkage and flame retardant, applied in the field of smart materials, can solve problems affecting disaster relief work, toxic gas, second disaster of life and property, etc., to reduce radiation dose, promote dispersion, reduce smoke and heat release Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

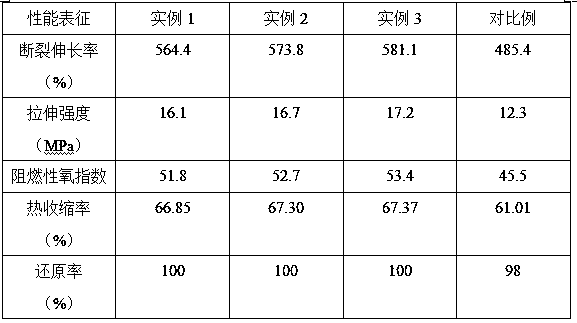

Examples

Embodiment Construction

[0022] Take 80~120g of magnesium nitrate, 40~50g of aluminum nitrate, 0.5~1.5g of lanthanum nitrate, 30~50g of melamine cyanurate, add 0.8~1.2L of deionized water, and put it in a constant temperature water bath at 25~30℃, at 300~ Stir at 400r / min for 30-40min, then add 100-200g montmorillonite, continue stirring for 1-2h to obtain a reaction solution, adjust the pH of the reaction solution to 11.0-11.5 with a mass fraction of 5% sodium hydroxide solution, and Insulate and react at 80°C for 1-2 hours. After the reaction, add 20-30g of cetyltrimethylammonium bromide, stir at 300-400r / min for 1-2 hours, then filter to obtain the filter residue, wash the filter residue with deionized water for 3- After 5 times, put it in a drying oven, dry it to constant weight at 105-110°C, put the dried filter residue into a pulverizer and grind it, and pass it through a 200-mesh sieve to obtain a flame retardant. Copolymerize ethylene-vinyl acetate Material, ethylene-1-octene copolymer, maleic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com