Nitrogen-doped porous carbon catalyst, preparation method of catalyst and preparation method of beta-isophorone

A nitrogen-doped porous carbon and isophorone technology is applied in the preparation of carbon-based compounds, the preparation of organic compounds, organic chemical methods, etc. Realize the effect of circular application, high value-added utilization, and reduction of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Take 0.50g of coal tar pitch (Shanxi Zhongqiang Coal Chemical Co., Ltd.) to grind and sieve to obtain 150 mesh powder, then mix it with 15.0g of isoquinoline and 20.0g of p-phenylenediamine for ultrasonic treatment, then cool and reflux at 350°C, and air atmosphere ( Under the condition of flow rate of 150mL / g coal tar pitch powder / min), the oxidative crosslinking reaction was carried out, and the reaction time was 3h. After the reaction system dropped to room temperature, the reaction solution was filtered and dried to obtain nitrogen-rich heavy organic matter.

[0062] The resulting nitrogen-rich heavy organic matter was placed in a quartz boat and placed in a tube furnace in a nitrogen atmosphere (flow rate of 250mL / g nitrogen-rich heavy organic matter / min) from room temperature at a rate of 1°C / min. Pre-carbonize at 250°C for 2h; then in a carbon dioxide atmosphere (flow rate of 200mL g nitrogen-rich heavy organic matter / min), continue to heat up to 700°C for 2h at ...

Embodiment 2

[0064] Relevant process parameters are shown in Table 1, the air flow rate is 200mL / g coal tar pitch powder / min, the flow rate of nitrogen, carbon dioxide, and ammonia are respectively 200mL / g nitrogen-rich heavy organic matter / min, and the remaining process parameters refer to Example 1 to prepare nitrogen Doped porous carbon catalysts B, C, D, E, the result analysis is shown in Table 2.

[0065] Table 1 Preparation process parameters of nitrogen-doped porous carbon catalyst

[0066]

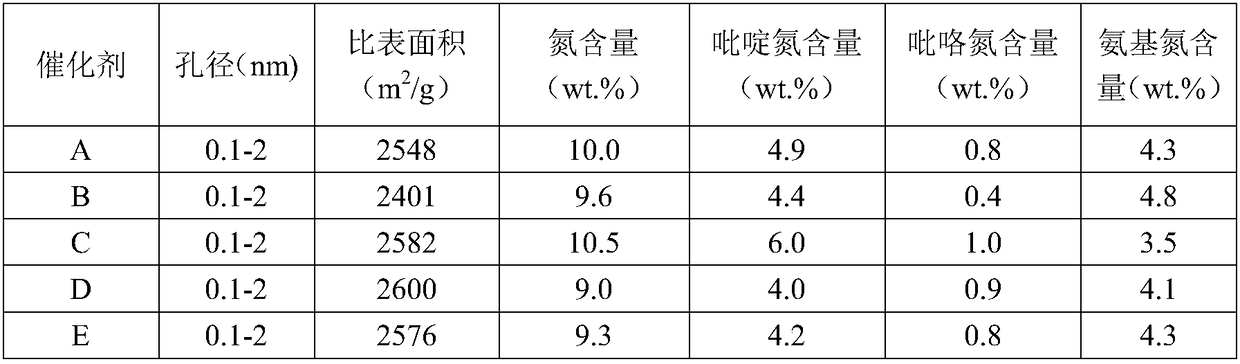

[0067] Table 2 Comparison table of structures and properties of nitrogen-doped porous carbon catalysts

[0068]

Embodiment 3

[0086] Add α-isophorone containing 0.5wt% nitrogen-doped porous carbon catalyst A to the still of a plate tower reactor with 30 plates, at 220°C, absolute pressure 0.1MPa, reflux ratio 10:1 The rectification reaction is carried out under certain conditions, and the α-IP isomerization reaction occurs. The reaction results are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com