Moisturizing co-transportation nano composition and preparation method and application thereof

A technology of nanocomposites and hygroscopic agents, which is applied in the field of moisturizing co-delivery nanocomposites and its preparation, can solve the problems of low active ingredient addition, poor skin permeability, easy crystallization and precipitation, etc., to achieve large drug loading, improve Good hydration ability and water dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

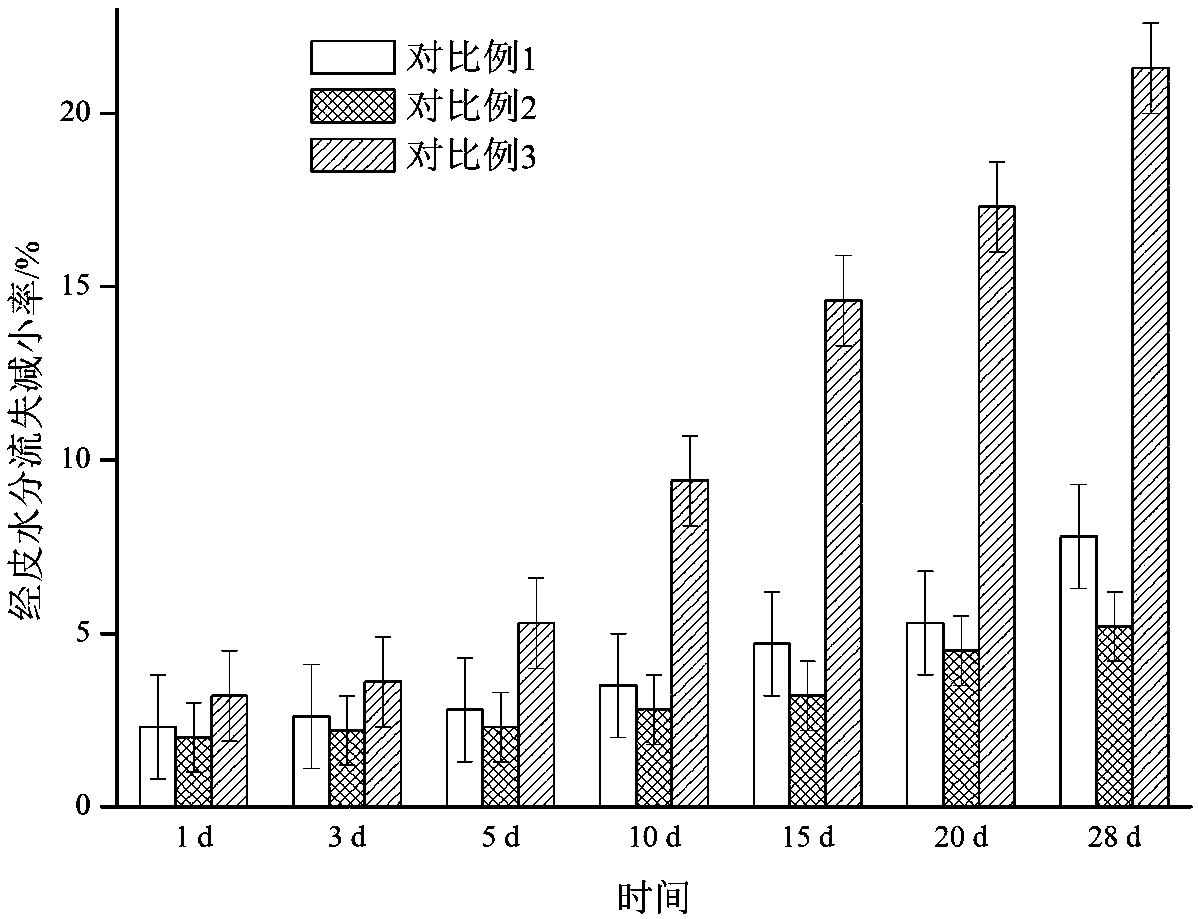

Image

Examples

preparation example Construction

[0050] The present invention provides a method for preparing the moisturizing co-delivery nanocomposite described in the above scheme, which includes the following steps:

[0051] In the present invention, liquid oils, emulsifiers, partial co-emulsifiers, physiological lipids, and emollients are mixed and stirred until completely dissolved to obtain an oil phase; the dissolution temperature is preferably 50°C to 75°C, and more It is preferably 55°C to 70°C; the dissolution time is preferably 10 to 30 minutes, more preferably 11 to 20 minutes. In the present invention, the dissolution process preferably uses a water bath to heat and dissolve.

[0052] In the present invention, the biological macromolecules combined with water and the remaining co-emulsifier are evenly mixed and dispersed, then mixed with the moisture absorbent and water, and stirred until completely dissolved to obtain the water phase; the dissolution temperature is preferably 50°C~ 75°C, more preferably 55°C to 70...

Embodiment 1

[0065] Combine 15.0% lauric acid polyethylene glycol glyceride, 20.0% fatty alcohol polyoxyethylene ether, 20.0% coco glucoside, 2.0% octyldodecanol, 8.0% ceramide type 3B, 0.2% wheat germ oil in Stir and dissolve in a water bath at a temperature of 70°C to obtain an oil phase for use;

[0066] Add 3.0% 1,3-butanediol to 3.0% hyaluronic acid to make the dispersion uniform, add 6.0% allantoin and 22.8% water, stir and dissolve in a water bath at a temperature of 70°C to obtain an aqueous phase for use;

[0067] After the oil phase and the water phase are obtained, the oil phase is added dropwise to the water phase at a rate of 2 drops / sec under the condition of a 70°C water bath. During the addition, the stirring rate is controlled to 600 rpm. After the mixing is completed, add 0.05% pentane Alcohol and 0.05% octanoyl hydroxamic acid are emulsified under high-speed shearing at 7000rpm for 9min to prepare micron-level dispersion;

[0068] The micron-level dispersion is subjected to hi...

Embodiment 2

[0071] Combine 5.0% isopropyl palmitate, 10.0% sorbitol laurate, 5.0% ceteareth, 5.0% diethylene glycol monoethyl ether, 10.0% glycerol, 0.5% ceramide type 2, 2.0 % Castor oil is stirred and dissolved in a water bath at a temperature of 55°C to obtain an oil phase for use;

[0072] Add 10.0% 1,3-butanediol to 6.0% hyaluronic acid to make it uniformly dispersed, add 2.0% panthenol and 44.5% water, stir and dissolve in a water bath at a temperature of 55°C to obtain an aqueous phase for use;

[0073] After obtaining the oil phase and the water phase, add the oil phase to the water phase dropwise at a rate of 2 drops / sec under the condition of 55°C water bath. During the dropping process, control the stirring speed to 600 rpm. After the mixing is completed, add 0.5% hexane Alcohol and 0.5% sorbitan caprylate, emulsify at 6000rpm for 3min under high-speed shearing to make a micron-level dispersion;

[0074] The micron-level dispersion is subjected to high-pressure homogenization treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com