Lignin enhanced polyvinyl chloride wood plastic foam composite material, and preparation method thereof

A polyvinyl chloride and wood-plastic foaming technology, which is applied in the field of polymer materials, can solve problems such as short service life and poor performance, and achieve the effects of improving mechanical properties, reducing water absorption, and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

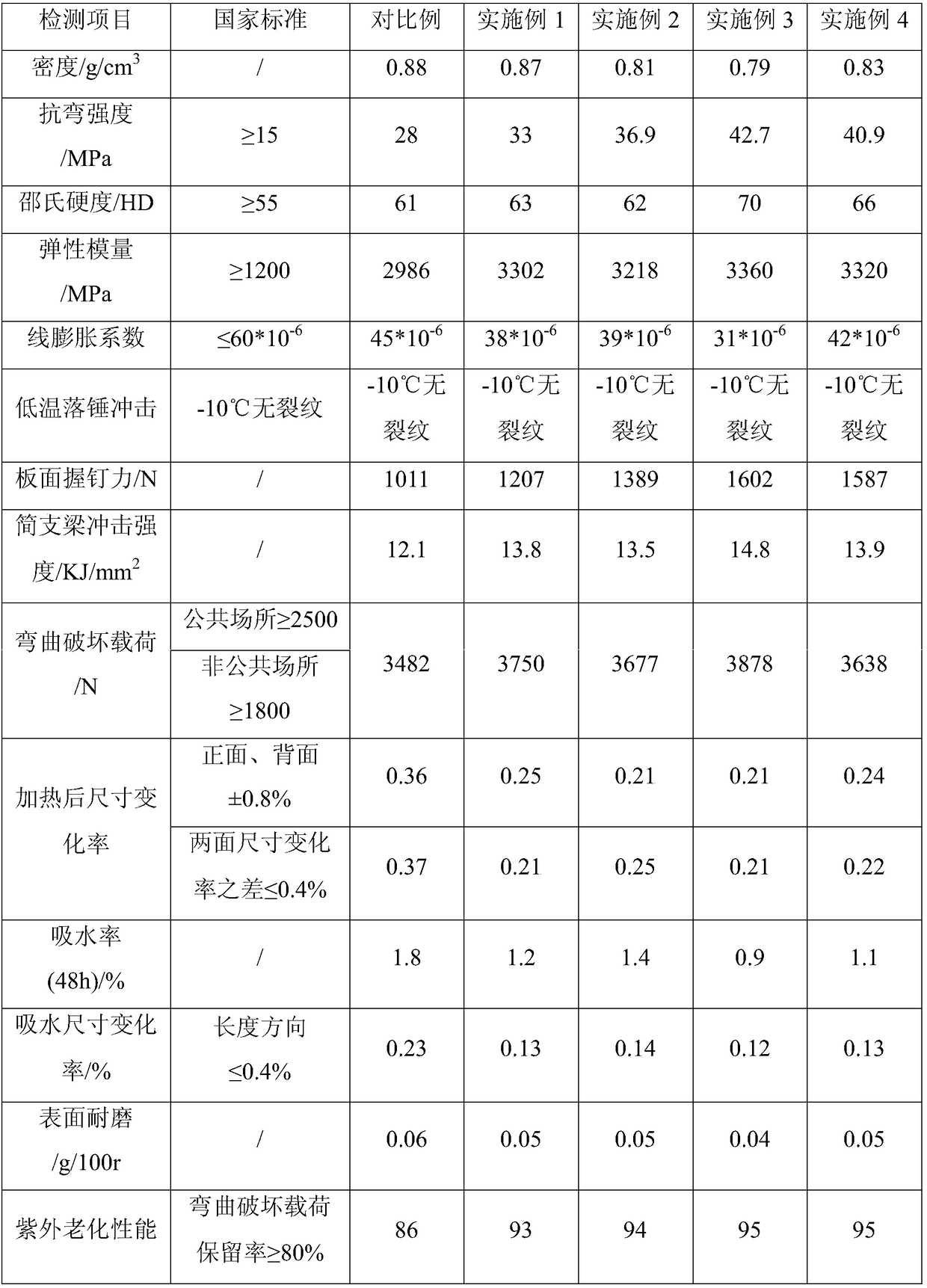

Embodiment 1

[0046] Raw materials: 100 parts of polyvinyl chloride, 60 parts of bamboo powder, 20 parts of calcium carbonate, 5 parts of composite lead salt stabilizer, 2 parts of polyethylene wax, 1 part of zinc stearate, 20 parts of alkali lignin, azodicarbonamide 3 parts, 15 parts of acrylate foam regulator, 5 parts of methacrylic acid-butadiene-styrene copolymer MBS. The preparation process is the same as in Comparative Example 1.

Embodiment 2

[0048]Raw materials: 100 parts of polyvinyl chloride, 30 parts of birch powder, 20 parts of calcium sulfate, 5 parts of calcium-zinc composite stabilizer, 1 part of polyethylene wax, 1 part of microcrystalline paraffin, 15 parts of enzymatic lignin, azodicarbonamide 3 parts, 1 part of sodium bicarbonate, 12 parts of acrylate foam regulator, 7 parts of high elastic acrylonitrile-styrene-butadiene copolymer ABS. The preparation process is the same as in Comparative Example 1.

Embodiment 3

[0050] Raw materials: 100 parts of polyvinyl chloride, 50 parts of poplar wood powder, 50 parts of talc powder, 6 parts of composite lead salt stabilizer, 2 parts of polyol ester, 1 part of stearic acid, 30 parts of organic solvent lignin, titanate 4 parts of joint agent, 2 parts of azodicarbonamide, 1 part of urea, 18 parts of acrylate foam regulator, 8 parts of ethylene-vinyl acetate copolymer EVA. The preparation process is the same as in Comparative Example 1.

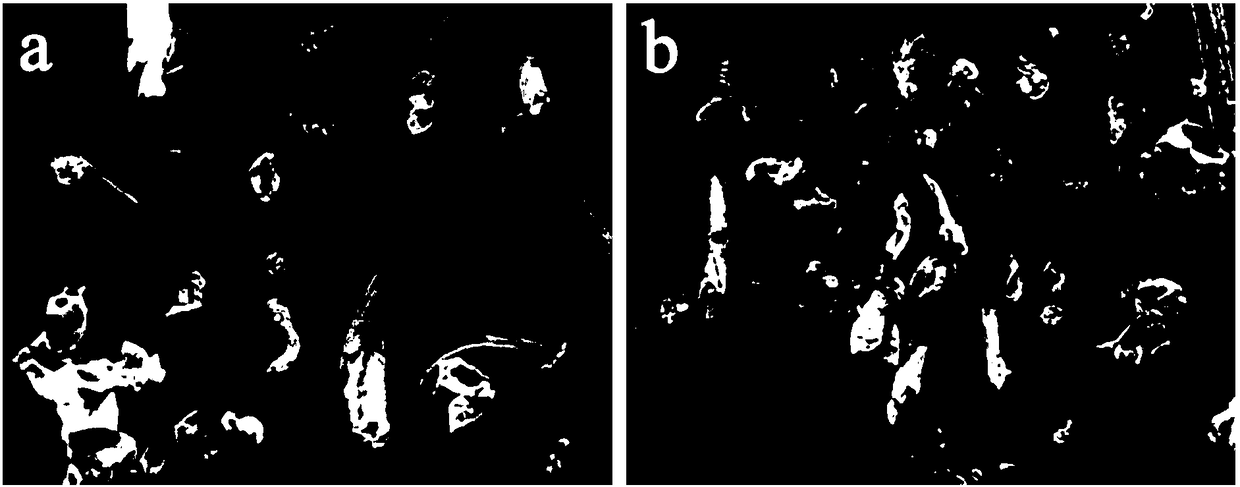

[0051] The interfacial bonding between lignocellulose and polymer matrix is a key factor affecting the performance of composite materials. figure 1 It is the SEM picture of the product in the comparative example and the product of this embodiment, showing the interface bonding status of the two. In figure a, there is a large gap between the interfaces of wood-plastic composite materials; in figure b, after adding lignin, lignin has a certain grafting effect, which solves the compatibility problem between wood fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com