Anti-cracking stainless steel welding wire and preparation method thereof

A stainless steel, anti-cracking technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems of high surface tension of stainless steel droplets, unsatisfactory welding process performance, and reduced mechanical properties of welds, so as to suppress hydrogen escape , Remarkable anti-cracking effect, prolonging the heat preservation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

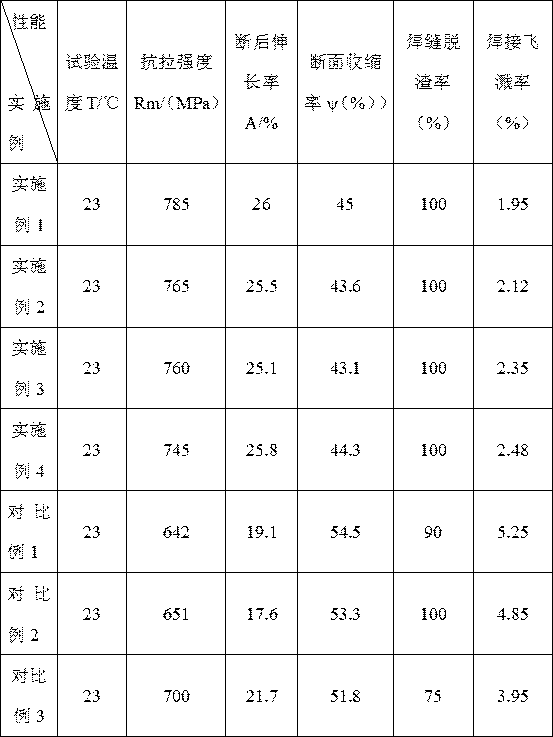

Examples

Embodiment 1

[0030] An anti-cracking stainless steel welding wire, which is composed of 304 stainless steel strip and a flux core, and the flux core is composed of the following components in terms of mass percentage: SiO 2 8%, 5 parts of rare earth fluoride, 3% of attapulgite clay, 5% of calcium oxalate, 10% of alloy powder composed of magnesium 30%, aluminum 20%, titanium 40%, boron 10%, metal chromium 5%, manganese content 55% ferromanganese 8%, molybdenum powder 2%, potassium carbonate 4%, alkali metal oxide 8% composed of lithium oxide, sodium oxide and potassium oxide in a mass ratio of 1:1:3, rutile 6%, and The amount is iron, and the sum of the mass percentages of the above components is 100%.

[0031] A preparation method of anti-cracking stainless steel welding wire, specifically comprising the steps of:

[0032] (1) Weigh SiO according to mass percentage 2 8%, 5 parts of rare earth fluoride, 3% of attapulgite clay, 5% of calcium oxalate, 10% of alloy powder, 5% of metal chro...

Embodiment 2

[0038] An anti-cracking stainless steel welding wire, which is composed of 304 stainless steel strip and a flux core, and the flux core is composed of the following components in terms of mass percentage: SiO 2 5%, 3 parts of rare earth fluoride, 1% of attapulgite clay, 3% of calcium oxalate, 12% of alloy powder composed of magnesium 35%, aluminum 15%, titanium 45%, boron 5%, metal chromium 5%, manganese content 60% ferromanganese 5%, molybdenum powder 1%, potassium carbonate 3%, alkali metal oxide composed of lithium oxide, sodium oxide and potassium oxide in a mass ratio of 1:2:1 5%, rutile 2%, and The amount is iron, and the sum of the mass percentages of the above components is 100%.

[0039] A preparation method of anti-cracking stainless steel welding wire, specifically comprising the steps of:

[0040] (1) Weigh SiO according to mass percentage 2 5%, 3 parts of rare earth fluoride, 1% of attapulgite clay, 3% of calcium oxalate, 12% of alloy powder, 5% of metal chrom...

Embodiment 3

[0046] An anti-cracking stainless steel welding wire, which is composed of 304 stainless steel strip and a flux core, and the flux core is composed of the following components in terms of mass percentage: SiO 2 10%, 8 parts of rare earth fluoride, 5% of attapulgite clay, 8% of calcium oxalate, 15% of alloy powder composed of magnesium 32%, aluminum 18%, titanium 45%, boron 5%, metal chromium 8%, manganese content 65% ferromanganese 10%, molybdenum powder 3%, potassium carbonate 5%, alkali metal oxide composed of lithium oxide, sodium oxide and potassium oxide in a mass ratio of 1:2:3 12%, rutile 9%, and The amount is iron, and the sum of the mass percentages of the above components is 100%.

[0047] A preparation method of anti-cracking stainless steel welding wire, specifically comprising the steps of:

[0048] (1) Weigh SiO according to mass percentage 2 10%, 8 parts of rare earth fluoride, 5% of attapulgite clay, 8% of calcium oxalate, 15% of alloy powder, 8% of metal c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com