Nickel-silver series hydrogenation catalysts and preparation method thereof

A hydrogenation catalyst and catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, selective hydrogenation refining, etc., can solve the problem of poor hydrogenation load and hydrogenation stability, uneven mixing of crystal particles, Catalyst strength deterioration and other problems, to achieve the effect of easy performance, simple process, and performance modulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

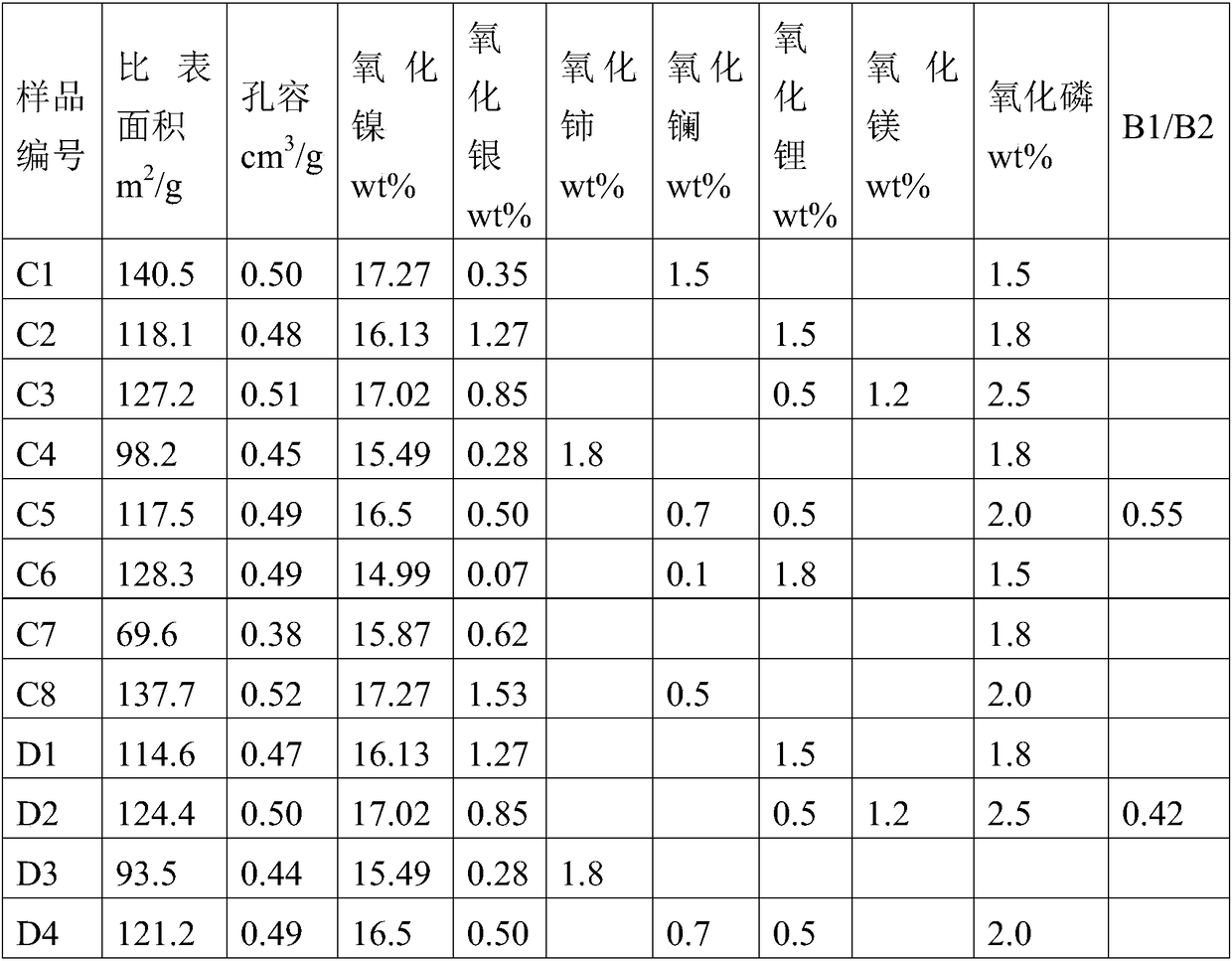

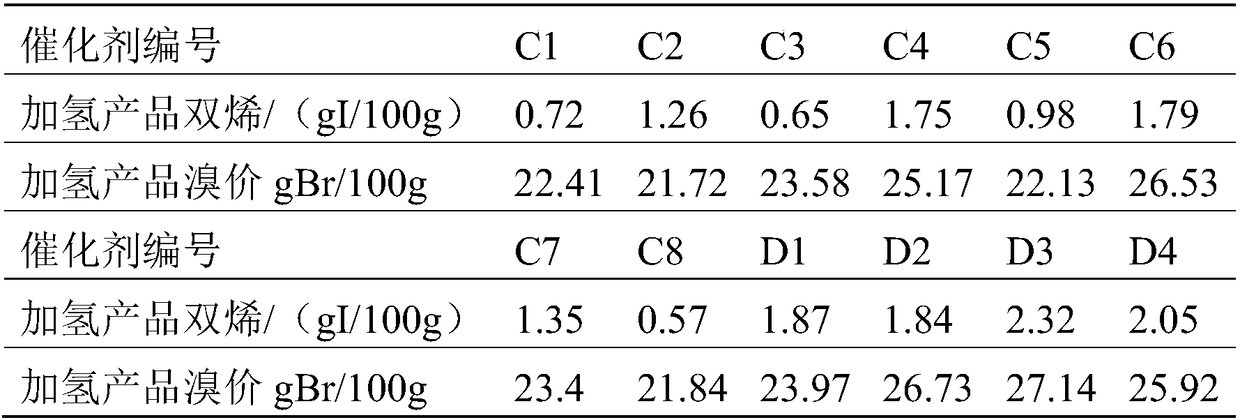

Examples

Embodiment 1

[0057] (1) Nickel-containing pseudoboehmite

[0058] Concentrate 3L to 65g Al 2 o 3 Aluminum nitrate solution per L and 1L nickel nitrate solution with a concentration of 11.8g NiO / L were mixed evenly and loaded into the container at the high position, and an ammonia solution with a concentration of 8wt% was prepared and loaded into the container at the high position, and the two containers were continuously wriggled The pump controls the flow rate and flows into a stainless steel container with a stirrer equipped with 3L bottom water and gas can be introduced into the bottom of the tank. The reaction temperature is 50°C, and the flow rate is controlled to adjust the pH value of the reaction system to 7.5. After the reaction is completed, add ammonia water to adjust the slurry. The pH value is 8.5, aging for 60 minutes, filtering and separating the mother liquor, and washing. Dry at 90°C for 3 hours and at 120°C for 2 hours to obtain nickel-containing pseudo-boehmite.

[00...

Embodiment 2

[0064] (1) Nickel-containing pseudoboehmite

[0065] Concentrate 4L to 50g Al 2 o 3 Aluminum nitrate solution per L and 0.5L concentration of nickel nitrate solution that is 14.5g NiO / L are mixed evenly and loaded into the container at the high position, and the ammonia solution with a concentration of 8wt% is prepared and packed into the container at the high position, and the two containers are connected under The peristaltic pump controls the flow rate and flows into a stainless steel container with 2L bottom water with agitator and gas at the bottom of the tank. The reaction temperature is 55°C, and the flow rate is controlled to adjust the pH value of the reaction system to 7.7. After the reaction, add ammonia water to adjust The pH value of the slurry is 8.6, aged for 30 minutes, filtered to separate the mother liquor, and washed. Dry at 120°C for 5 hours to obtain nickel-containing pseudo-boehmite.

[0066] (2) Nickel-containing carrier

[0067] Weigh the prepared n...

Embodiment 3

[0078] (1) Nickel-containing pseudoboehmite

[0079] Dilute 1L concentration to 50g Al 2 o 3 / L of aluminum sulfate solution and 0.5L of nickel nitrate solution with a concentration of 6g NiO / L are mixed evenly and placed in a container at a high position, and the prepared concentration is 50g Al 2 o 3 / / 3 L of sodium metaaluminate solution is put into a container at a high position, and the two containers are connected with a peristaltic pump to control the flow rate and flow into a stainless steel container with a stirrer equipped with 2L of bottom water and the bottom of the tank can be fed into the gas, the reaction temperature 60°C, control the flow rate to adjust the pH value of the reaction system to 9, adjust the pH value of the slurry to 9.6 by adding ammonia water dropwise, age for 30 minutes after the reaction, filter and separate the mother liquor, and wash. Dry at 90°C for 3 hours and at 120°C for 2 hours to obtain nickel-containing pseudo-boehmite.

[0080] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com