Hydrogenation method for pyrolysis gasoline

A technology for pyrolysis gasoline and hydrogenation catalyst, which is applied in the field of hydrogenation of diene unsaturated hydrocarbons, and can solve the problems of incomplete dissolution of active metal components, difficult combination, and poor catalyst strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

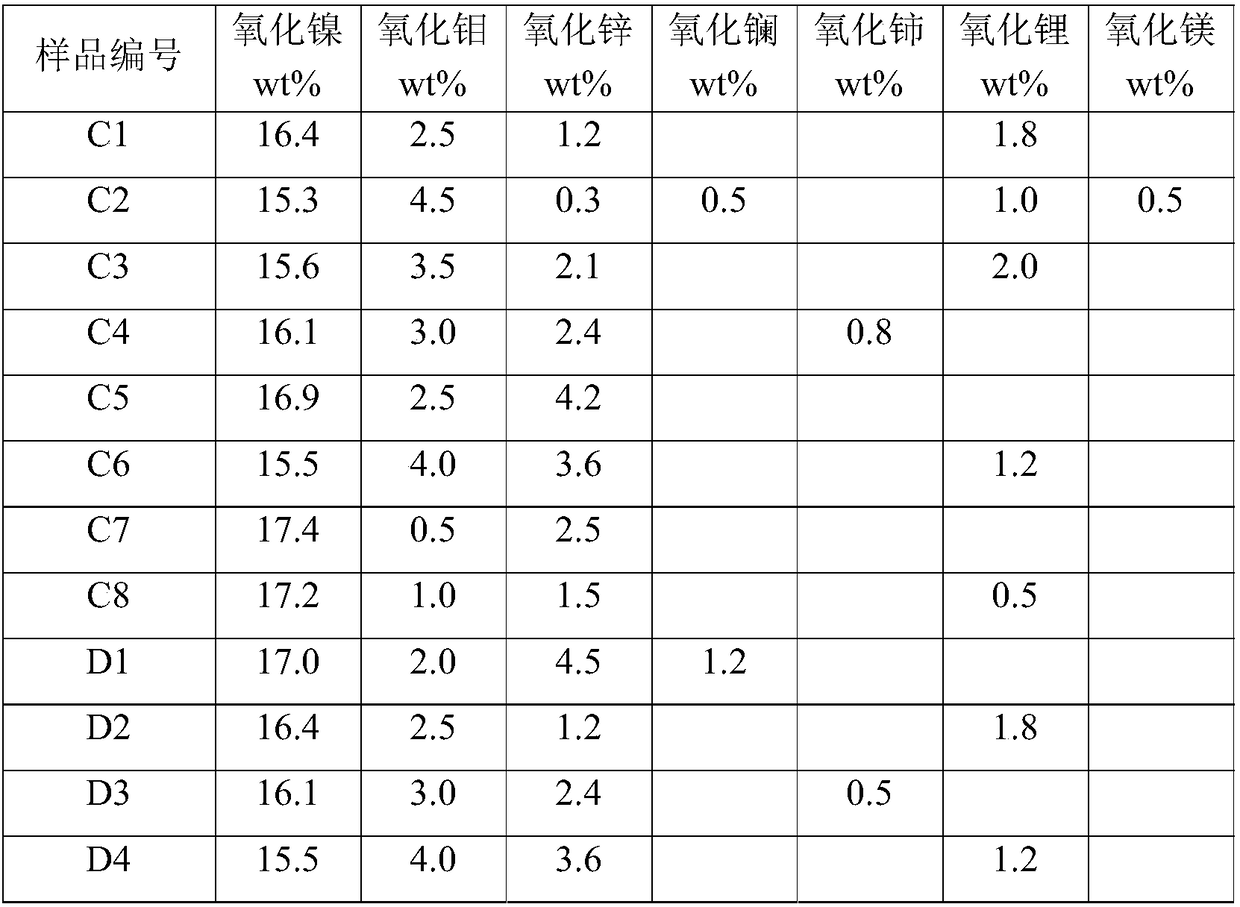

Embodiment 1

[0066] Concentrate 1L to 48g Al 2 o 3 / L of aluminum sulfate solution and 1L of nickel nitrate solution with a concentration of 8.3g NiO / L are mixed evenly and placed in a container at a high position, and the prepared concentration is 70g Al 2 o 3 / L Sodium metaaluminate solution 2L is put into the container at the high position, and the peristaltic pump is connected under the two containers to control the flow rate and flow into the stainless steel container with 3L bottom water with agitator and gas at the bottom of the tank, the reaction temperature is 54 ℃, control the flow rate to adjust the pH value of the reaction system to 9.3, adjust the pH value of the slurry to 9.5 by adding ammonia water dropwise, age for 30 minutes after the reaction, filter and separate the mother liquor, wash, and dry at 120°C for 3 hours to obtain pseudo-boehmite containing nickel . Weigh the prepared nickel-containing pseudo-boehmite, mix and knead it with nitric acid, citric acid, kale po...

Embodiment 2

[0068] Dilute 1L concentration to 50g Al 2 o 3 / L of aluminum sulfate solution and 0.5L of nickel nitrate solution with a concentration of 6g NiO / L are mixed evenly and placed in a container at a high position, and the prepared concentration is 150g Al 2 o 3 / / 1 L of sodium metaaluminate solution is put into a container at a high position, and the two containers are connected with a peristaltic pump to control the flow rate and flow into a stainless steel container with a stirrer equipped with 5 L of bottom water and the bottom of the tank can be fed into the gas. The reaction temperature 60°C, control the flow rate to adjust the pH value of the reaction system to 9, adjust the pH value of the slurry to 9.6 by adding ammonia water dropwise, age for 40 minutes after the reaction, filter and separate the mother liquor, and wash. Dry at 90°C for 3 hours and at 120°C for 3 hours to obtain nickel-containing pseudo-boehmite. Weigh the prepared nickel-containing pseudo-boehmite, m...

Embodiment 3

[0070] Concentrate 1L to 190g Al 2 o 3 / L sodium metaaluminate solution and 1L nickel nitrate solution with a concentration of 8g NiO / L are mixed evenly and placed in a stainless steel container with a stirrer and the bottom of the tank can be fed with gas, and a mixed gas of carbon dioxide and air is introduced, and the mixed gas Medium carbon dioxide concentration is 60v%, flow rate is 5Nm 3 / h. The reaction temperature is 40° C., the pH value at the end of the reaction is 10, stop feeding carbon dioxide, age for 35 minutes, filter and separate the mother liquor, and wash. Dry at 110°C for 3 hours to obtain nickel-containing pseudo-boehmite. Weigh the prepared nickel-containing pseudo-boehmite, mix and knead it with nitric acid, phosphoric acid, citric acid, scallop powder and water to form a plastic body, extrude into a strip, then dry at 120°C for 4 hours, and roast at 620°C for 4 hours to obtain nickel-containing carrier. Lithium carbonate and citric acid aqueous sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com