Universal waterborne hub baking paint

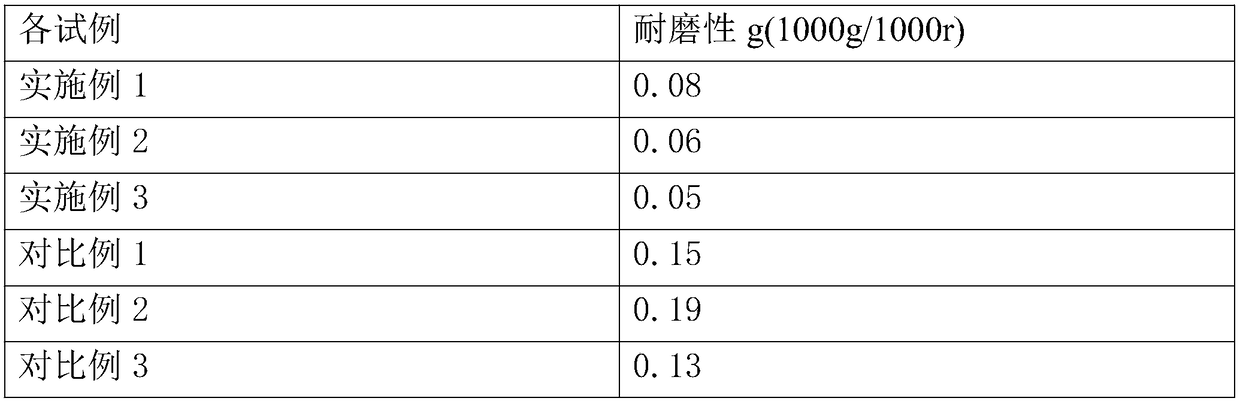

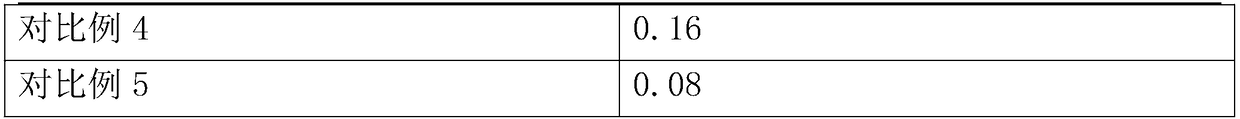

A general-purpose, water-based technology, applied in the direction of fire-resistant coatings, coatings, etc., can solve the problems of reduced wear resistance of wheel hub paint, time-consuming and labor-intensive problems, and achieve the effect of beautiful paint film, good wear resistance and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: a kind of universal type water-based wheel hub baking varnish comprises following weight parts material:

[0046] 15 parts of water;

[0047] 25 parts of water-based acrylic resin;

[0048] 5 parts of amino resin;

[0049] 3 parts of isopropanol;

[0050] 2 parts of dispersant;

[0051] 2 parts of defoamer;

[0052] Leveling agent 1 part;

[0053] 1 part adhesion promoter;

[0054] 1 part of wetting agent;

[0055] 1 part of film-forming agent;

[0056] 2 parts of PH regulator;

[0057] 1 part of solubilizer;

[0058] 1 part of 2-[acetoxy (polyoxyethylene) propyl] heptamethyltrisiloxane;

[0059] 2 parts of 1,1,3,3-tetramethyl-1,3 bis[3-(oxiranylmethoxy)propyl]disiloxane;

[0060] 1 part of tripropylene glycol diacrylate;

[0061] 0.5 parts of 2,2,6,6-tetramethyl-4-piperidine stearate;

[0062] 1 part of resorcinol monobenzoate;

[0063] 2 parts of calcium bis(2,2,6,6,-tetramethyl-3,5-heptanedionate).

[0064] It also includes 5 parts of wat...

Embodiment 2

[0084] A general-purpose water-based wheel hub baking varnish, comprising the following materials in parts by weight:

[0085] 25 parts of water;

[0086] 40 parts of water-based acrylic resin;

[0087] 8 parts of amino resin;

[0088] 4 parts isopropanol;

[0089] 3 parts of dispersant;

[0090] 2 parts of defoamer;

[0091] Leveling agent 2 parts;

[0092] 1.5 parts of adhesion promoter;

[0093] 1.5 parts of wetting agent;

[0094] 1.5 parts of film-forming agent;

[0095] 3 parts of PH regulator;

[0096] 1.5 parts of solubilizer;

[0097] 1.5 parts of 2-[acetoxy (polyoxyethylene) propyl] heptamethyltrisiloxane;

[0098] 3 parts of 1,1,3,3-tetramethyl-1,3 bis[3-(oxiranylmethoxy)propyl]disiloxane;

[0099] 2 parts of tripropylene glycol diacrylate;

[0100] 0.8 parts of 2,2,6,6-tetramethyl-4-piperidine stearate;

[0101] 1.5 parts of resorcinol monobenzoate;

[0102] 2.5 parts of calcium bis(2,2,6,6,-tetramethyl-3,5-heptanedionate).

[0103] It also includes ...

Embodiment 3

[0123] Embodiment 3: a kind of general-purpose water-based wheel hub baking varnish, comprises following material by weight:

[0124] Water: 40 parts;

[0125] 60 parts of water-based acrylic resin;

[0126] 10 parts of amino resin;

[0127] 6 parts of isopropanol;

[0128] 4 parts of dispersant;

[0129] 3 parts of defoamer;

[0130] Leveling agent 3 parts;

[0131] Adhesion promoter 2 parts;

[0132] 2 parts of wetting agent;

[0133] 2 parts of film-forming agent;

[0134] 5 parts of pH regulator;

[0135] 2 parts of solubilizer;

[0136] 2 parts of 2-[acetoxy (polyoxyethylene) propyl] heptamethyltrisiloxane;

[0137] 4 parts of 1,1,3,3-tetramethyl-1,3 bis[3-(oxiranylmethoxy)propyl]disiloxane;

[0138] 3 parts of tripropylene glycol diacrylate;

[0139] 1 part of 2,2,6,6-tetramethyl-4-piperidine stearate;

[0140] 2 parts of resorcinol monobenzoate;

[0141] 3 parts of calcium bis(2,2,6,6,-tetramethyl-3,5-heptanedionate).

[0142] It also includes 10 parts of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com