Thermoplastic polymer foam bead and method for preparing same

A technology of thermoplastic polymers and expanded beads, applied in the direction of climate sustainability, sustainable manufacturing/processing, chemical industry, etc., can solve the problem of increasing the post-processing separation and drying process, affecting the smooth discharge of solid materials, and not being able to complete smoothly Foaming and other problems, to achieve the effect of improving foaming ratio and mechanical properties, short heating time, and not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

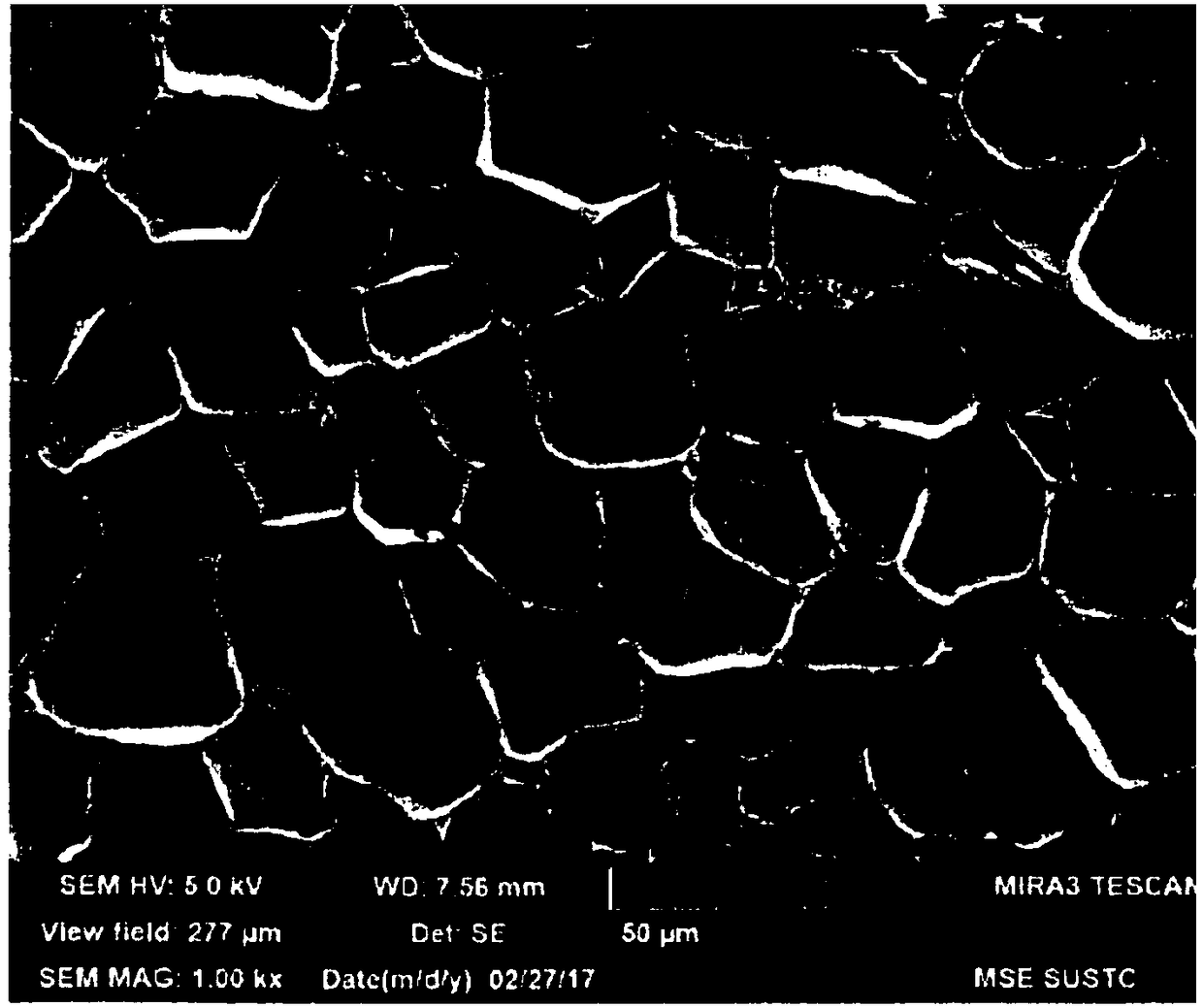

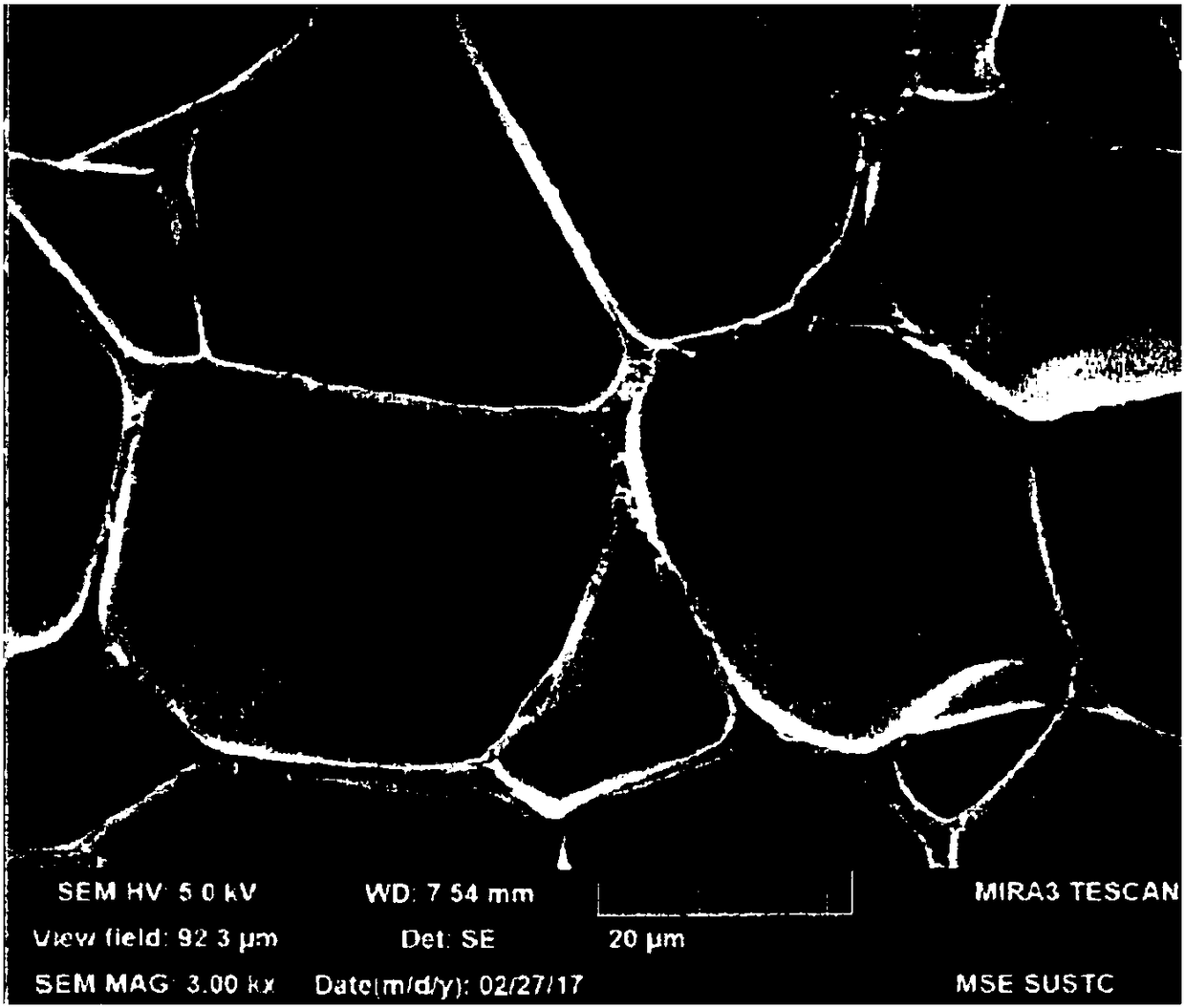

[0043] Weigh 100 parts of foaming grade polypropylene, resin MI at 3g / 10min (2.16kg weight at 190°C), 1.5 parts of nucleating agent (talcum powder), 0.1 part of viscosity modifier (polyethylene glycol diglycidylglycerol) ether), 8 parts of cell stabilizer (sodium alkyl sulfonate), mixed and extruded by a twin-screw extruder, cut into particles with a particle diameter of 0.5mm, and the weight of 100 particles of particles is 0.4g, and the resin particles are dried for subsequent use As particles to be expanded.

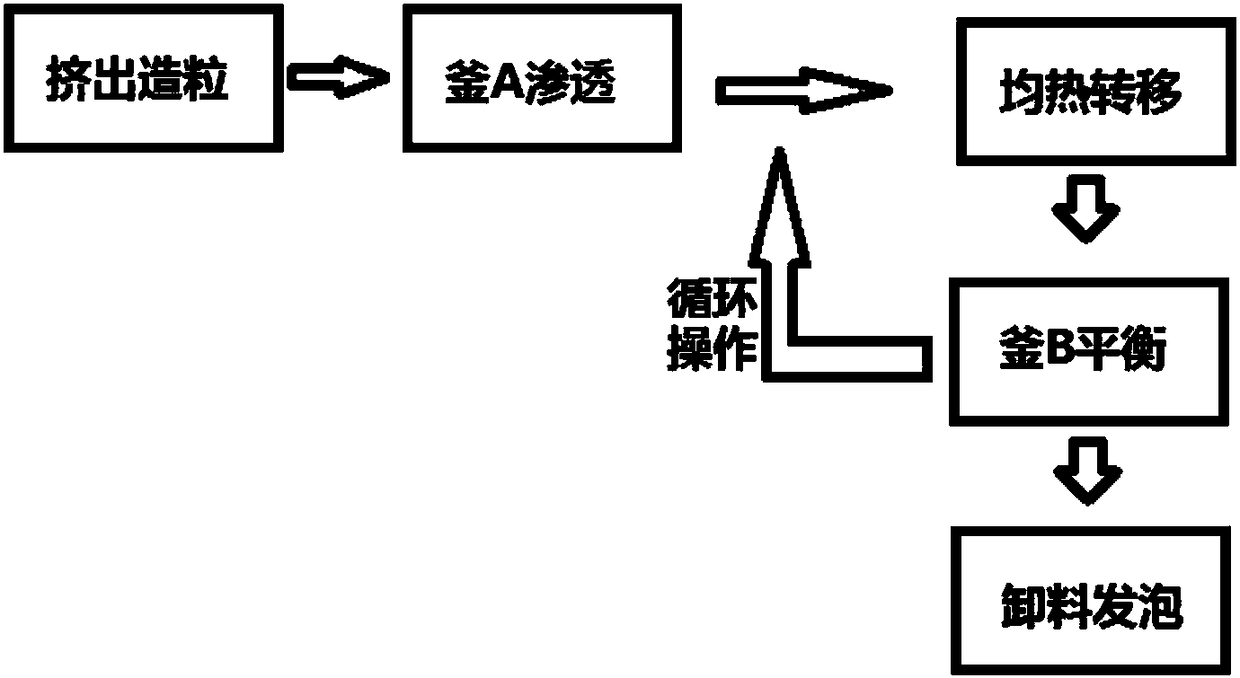

[0044] The preparation method of polypropylene foam beads is as follows:

[0045] (1) Place the granules to be expanded in a high-pressure reactor A, keep the constant temperature at 80°C, replace the air in the kettle, fill it with carbon dioxide to a supercritical state, control the pressure in the kettle at 15MPa, and infiltrate for 15 minutes under pressure;

[0046] (2) Transport the materials in the high-pressure reactor A to the reactor B through a magnetically ...

Embodiment 2

[0050] Weigh 100 parts of foaming grade polypropylene, resin MI at 3g / 10min (2.16kg weight at 190°C), 2 parts of nucleating agent (calcium carbonate), 6 parts of viscosity regulator (1,4-butanediol di Glycidyl ether), 8 parts of cell stabilizer (sodium alkylaryl sulfonate), mixed and extruded by a twin-screw extruder, cut into particles with a particle diameter of 1.5mm, and the weight of 100 particles of particles is 1.0g , the resin granules are dried and used as the granules to be expanded.

[0051] The preparation method of polypropylene foam beads is as follows:

[0052] (1) Put the granules to be expanded in the autoclave A, keep the constant temperature at 120°C, replace the air in the autoclave, fill it with carbon dioxide to a supercritical state, control the pressure in the autoclave at 7.3MPa, and infiltrate for 60 minutes under pressure.

[0053] (2) Transport the materials in the high-pressure reactor A to the reactor B through a magnetic-sealed stirring device. ...

Embodiment 3

[0057] Weigh 100 parts of foaming grade polyethylene terephthalate, the IV value is 1.10-1.40dL / g (using Ubbelohde viscometer at 30°C with phenol and 1,1,2,2-tetrachloroethylene 6:4 mixed solvent of alkane to detect), 5 parts of nucleating agent (kaolin), 8 parts of viscosity modifier (glycerol diglycidyl ether), 2 parts of cell stabilizer (alkylphenol polyether), through The twin-screw extruder is mixed and extruded, cut into particles with a particle diameter of 1.5mm, and the weight of one hundred particles is 1.0g, and the resin particles are dried and used as particles to be expanded.

[0058] The preparation method of polyethylene terephthalate expanded beads is as follows:

[0059] (1) Place the particles to be expanded in the autoclave A, keep the constant temperature at 180°C, replace the air in the autoclave, fill it with carbon dioxide to a supercritical state, control the pressure in the autoclave at 12MPa, and infiltrate for 180min under pressure.

[0060] (2) Tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com