Fireproof insulated door and manufacturing method thereof

A technology of heat-insulating doors and heat-insulating layers, which is applied in the field of fire-proof doors, can solve problems such as thermal insulation performance needs to be improved, and achieve better fire-proof effect, low cost and good fire-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

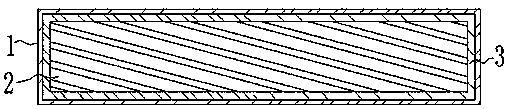

Image

Examples

Embodiment 1

[0035] Step 1): First take five steel plates with a thickness of 1cm, and weld them into a cuboid-shaped cavity, leaving one side open, and the internal height of the cavity is 2.5cm;

[0036] Step 2): Use a grinder to grind the inner wall of the cavity to a rough surface with a roughness of 1.4 μm;

[0037] Step 3): Put a layer of waterproof glue on the inner wall of the cavity, and stick glass wool with a thickness of 2.5mm to the inner wall of the cavity to form an insulation layer;

[0038] Step 4): Take another 1cm thick steel plate that can seal the opening of the cavity and perform the same operation from step 2) to step 3);

[0039] Step 5): Prepare the fireproof and heat insulation layer: take 15 parts of black mud powder, 8 parts of polytetrafluoroethylene, 3 parts of compound animal protein foaming agent, 12 parts of phenolic resin, 5 parts of carboxylated nitrile rubber and 1 part of tea soap Put the element into the mixer and stir well to make it evenly mixed to ...

Embodiment 2

[0042] Step 1): Take five aluminum alloy plates with a thickness of 1.5cm, and weld them into a cuboid-shaped cavity, leaving one side open, and the internal height of the cavity is 3.5cm;

[0043] Step 2): Use a grinder to grind the inner wall of the cavity to a rough surface with a roughness of 1.8 μm;

[0044] Step 3): Put a layer of waterproof glue on the inner wall of the cavity, and stick glass wool with a thickness of 3.5mm to the inner wall of the cavity to form an insulation layer;

[0045] Step 4): Take another 1.5cm thick aluminum alloy plate that can seal the opening of the cavity and perform the same operation from step 2) to step 3);

[0046] Step 5): Prepare the fireproof and heat insulation layer: take 20 parts of black mud powder, 12 parts of polytetrafluoroethylene, 5 parts of compound animal protein foaming agent, 15 parts of phenolic resin, 8 parts of carboxylated nitrile rubber and 1.5 parts of tea soap Put the element into the mixer and stir well to make...

Embodiment 3

[0049] Step 1): Cast a cuboid cavity in the mold by smelting steel, leaving one side open, the wall thickness is 1.2cm, and the internal height of the cavity is 2.7cm;

[0050] Step 2): Use a grinder to grind the inner wall of the cavity to a rough surface with a roughness of 1.5 μm;

[0051] Step 3): Put a layer of waterproof glue on the inner wall of the cavity, take glass wool with a thickness of 2.7mm and stick it on the inner wall of the cavity to form an insulation layer;

[0052] Step 4): Take another 1.2cm thick steel plate that can seal the opening of the cavity and perform the same operation from step 2) to step 3);

[0053] Step 5): Prepare the fireproof and heat insulation layer: take 15 parts of slag powder, 8 parts of polytetrafluoroethylene, 5 parts of compound animal protein foaming agent, 12 parts of phenolic resin, 5 parts of liquid nitrile rubber and 1 part of tea saponin Put it into a mixer and stir it well to make it evenly mixed to get the fireproof and he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com