A kind of high hardenability high boron cast steel and preparation method thereof

A high hardenability, high boron technology, applied in the field of anti-wear metal materials, can solve the problems of surface oxidation, low toughness, small quenching stress and other problems of the workpiece, and achieve the effects of short production cycle, simple process and low residual stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

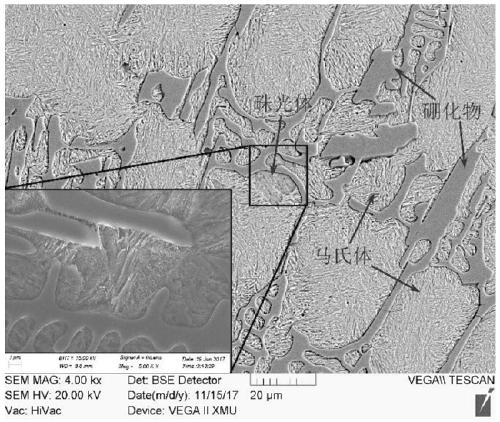

Image

Examples

preparation example Construction

[0030] A method for preparing high-hardenability high-boron cast steel disclosed by the invention comprises the following steps:

[0031] 1) Take scrap steel, ferrochrome, ferromanganese, carbon steel, ferroboron, pure copper rod and pure nickel rod as the furnace charge, first mix scrap steel, ferrochrome, ferromanganese and carbon steel, then fill them into the melting furnace, and heat until melting ;

[0032] 2) After pulverizing and drying the ferroboron, place it at the bottom of the ladle, and add the ferroboron into the melting furnace by pouring into the ladle;

[0033] 3) Raise the temperature of the melting furnace to 1500~1580°C, add deoxidizer aluminum wire for deoxidation, and then add pure copper rods and nickel rods after the furnace charge is completely melted;

[0034] 4) When the temperature of the molten steel reaches 1400~1480°C, pour it into a casting, then anneal the casting, and air cool it to room temperature to produce a high hardenability and high b...

Embodiment 1

[0040] Adopt 500 kilograms of medium-frequency induction furnaces to smelt the high-boron cast steel of the present invention, and its manufacturing process steps are:

[0041] 1) Mix steel scrap, ferrochrome, ferromanganese and carbon steel and heat to melt;

[0042] 2) Break the ferroboron into small pieces smaller than 15mm, after drying below 250°C, place it at the bottom of the ladle, and add the ferroboron by pouring into the ladle;

[0043] 3) Raise the temperature of the melting furnace to 1560°C, add deoxidizer aluminum wire, and add pure copper rods and pure nickel rods after the furnace charge is completely melted;

[0044] 4) When the temperature of the molten steel reaches 1450°C, it is directly poured into castings, and finally the castings are annealed at 200°C for 3 hours for stress relief, and then air cooled to room temperature.

[0045] The specific composition of the high-boron cast steel obtained in this embodiment is shown in Table 2. Its hardness reaches ...

Embodiment 2

[0047] Adopt 500 kilograms of medium-frequency induction furnaces to smelt the high-boron cast steel of the present invention, and its manufacturing process steps are:

[0048] 1) Mix steel scrap, ferrochrome, ferromanganese and carbon steel and heat to melt;

[0049] 2) Break the ferroboron into small pieces smaller than 15mm, after drying below 250°C, place it at the bottom of the ladle, and add the ferroboron by pouring into the ladle;

[0050] 3) Raise the temperature of the smelting furnace to 1560°C, add deoxidizer aluminum wire, and add pure nickel rods after the furnace charge is completely melted;

[0051] 4) When the temperature of the molten steel reaches 1450°C, it is directly poured into castings, and finally the castings are annealed at 200°C for 3 hours for stress relief, and then air cooled to room temperature.

[0052] The specific composition of the high-boron cast steel obtained in this embodiment is shown in Table 2. Its hardness reaches 65.2 ± 1HRC, its i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| residual stress | aaaaa | aaaaa |

| residual stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com