Method for extracting and separating tungsten and molybdenum from molybdenum-contained ammonium tungstate solution

A technology of molybdenum tungstic acid and ammonium solution, applied in the direction of improving process efficiency, etc., can solve problems such as large amount of waste water, decline in the grade of molybdenum products, unfavorable added value of molybdenum products, etc., and achieve the effect of high separation efficiency and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

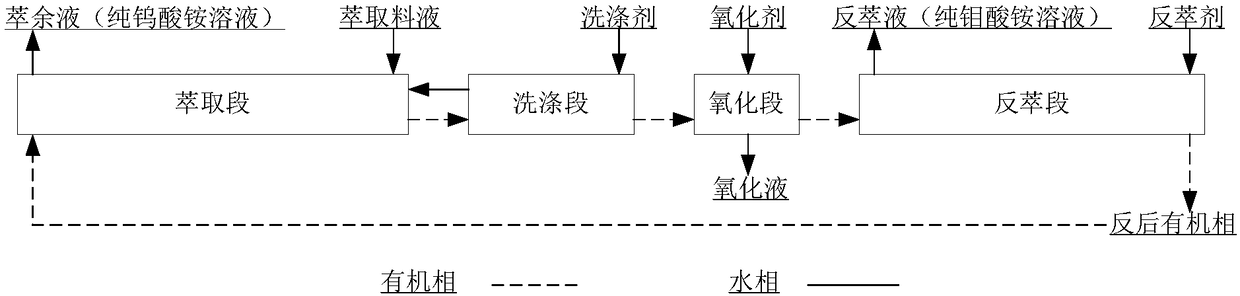

Method used

Image

Examples

Embodiment 1

[0032] Aqueous phase material liquid: industrial molybdenum-containing ammonium tungstate solution after thiolation treatment, in which WO 3 172.9g·L -1 , Mo 0.77g / L, total S 2- 3.0g / L, Mo / WO 3 = 0.45%, pH 9.75.

[0033] Organic phase: 10% N263+20% isooctyl alcohol+70% No. 260 solvent oil (percentage by volume), wherein N263 is the product code of domestic quaternary ammonium salt extractant, is a kind of methyl trialkylammonium chloride, wherein The number of carbon atoms in the three alkyl groups is 8-10, respectively. Before extraction, contact the organic phase with ammonium bicarbonate-ammonium carbonate mixed solution (total carbon concentration is 2.5mol / L, total nitrogen concentration is 3.5mol / L) in advance to chlorinate the methyl trialkyl in the organic phase Ammonium is converted to a mixture of bicarbonates and carbonates of methyltrialkylammonium.

[0034] Detergent: ammonium bicarbonate-ammonium carbonate mixed solution, wherein the total carbon concentrati...

Embodiment 2

[0041] Aqueous phase material liquid: industrial molybdenum-containing ammonium tungstate solution after thiolation treatment, in which WO 3 300.5g·L -1 , Mo 6.5g / L, total S 2- 13.5g / L, pH 10.2.

[0042] Organic phase: 10% methyl trioctyl ammonium chloride + 30% sec-octanol + 60% sulfonated kerosene (volume percentage). Before the extraction, the organic phase was contacted with ammonium bicarbonate-ammonium carbonate mixed solution (total C 2.5mol / L, total N 3.5mol / L) in advance so that the methyl trioctyl ammonium chloride in the organic phase was converted into formazan Mixture of bicarbonate and carbonate salts of trioctylammonium.

[0043] Detergent: ammonium bicarbonate-ammonium carbonate mixed solution, in which the total C is 1.0 mol / L, and the total N is 1.0 mol / L.

[0044] Oxidizing agent: 10% H 2 o 2 solution.

[0045] Stripping agent: ammonium bicarbonate-ammonium carbonate mixed solution, in which the total C is 3.0 mol / L, and the total N is 6.0 mol / L.

[...

Embodiment 3

[0050] Aqueous phase material liquid: molybdenum-containing ammonium tungstate solution after sulfidation treatment, in which WO 3 80.0g·L -1 , Mo 12.0g / L, total S 2- 18g / L, pH 8.5.

[0051] Organic phase: 15% methyl trioctyl ammonium chloride + 40% sec-octanol + 55% aviation kerosene (volume percentage). Before the extraction, the organic phase was contacted with ammonium bicarbonate-ammonium carbonate mixed solution (total C 2.5mol / L, total N 3.5mol / L) in advance so that the methyl trioctyl ammonium chloride in the organic phase was converted into formazan Mixture of bicarbonate and carbonate salts of trioctylammonium.

[0052] Detergent: ammonium bicarbonate-ammonium carbonate mixed solution, in which the total C is 3.5mol / L, and the total N is 7.0mol / L.

[0053] Oxidizing agent: 10% H 2 o 2 solution.

[0054] Stripping agent: ammonium bicarbonate-ammonium carbonate mixed solution, in which the total C is 3.0 mol / L, and the total N is 6.0 mol / L.

[0055] Operation: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com